A kind of airflow premixing method for preparing rice starch phosphate monoester

A rice starch and phosphate monoester technology, which is applied in the field of starch deep processing, can solve the problems of waste of starch resources, etc., and achieve the effects of stable product quality, high degree of esterification, and uniform esterification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

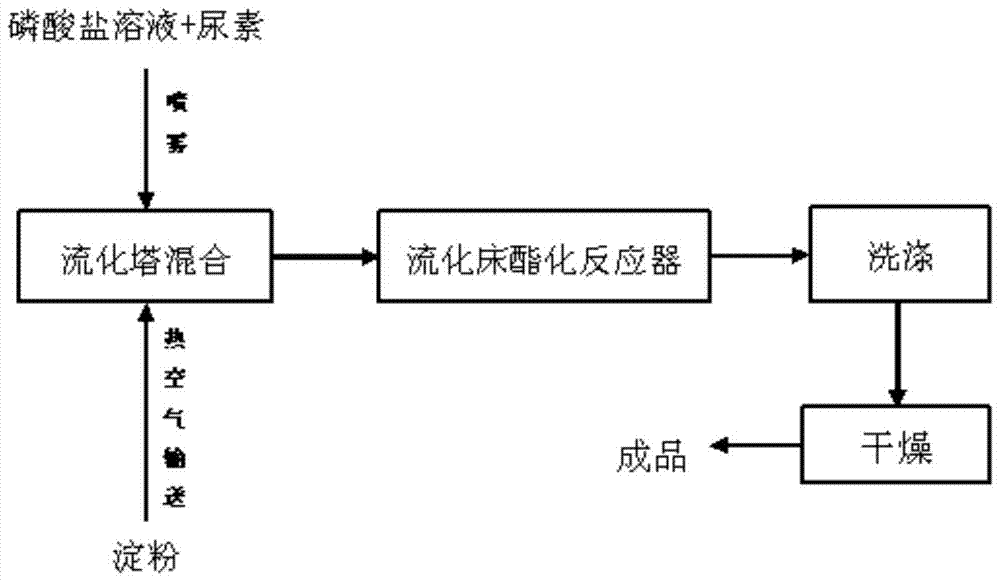

Method used

Image

Examples

Embodiment 1

[0036] (1) Add 35 parts of sodium dihydrogen phosphate, 96 parts of disodium hydrogen phosphate and 90 parts of water, and add 8 parts of urea to make a mixed solution, adjust the pH to 5.5, and heat to 50°C;

[0037] (2) Convey 180 parts of rice starch into the air conveyor with hot air at 50°C, and use a sprayer to spray the heated orthophosphate mixed solution into a mist at the front end 1 / 3 of the air conveyor. Fully mixed with starch in the conveyor;

[0038] (3) The mixture of starch and orthophosphate mixed solution coming out from the air conveyor directly enters a fluidized bed reactor, and is heated and reacted at 150° C. for 2.5 hours;

[0039] (4) After the reaction, the reactants were washed, and then air-dried or vacuum-dried at 50° C. for 24 hours to obtain rice starch phosphate monoester with a substitution degree of 0.018.

Embodiment 2

[0041] (1) Add 30 parts of sodium dihydrogen phosphate, 100 parts of disodium hydrogen phosphate and 90 parts of water, and add 9 parts of urea to make a mixed solution, adjust the pH to 6, and heat to 45°C;

[0042] (2) Convey 180 parts of rice starch into the air conveyor with hot air at 50°C, and use a sprayer to spray the heated orthophosphate mixed solution into a mist at the front end 1 / 3 of the air conveyor. Fully mixed with starch in the conveyor;

[0043] (3) The mixture of starch and orthophosphate mixed solution coming out of the air conveyor directly enters a fluidized bed reactor, and heats and reacts at 130° C. for 4 hours;

[0044] (4) After the reaction, the reactants were washed, and then air-dried or vacuum-dried at 50° C. for 24 hours to obtain rice starch phosphate monoester with a substitution degree of 0.021.

Embodiment 3

[0046] (1) Add 40 parts of sodium dihydrogen phosphate, 85 parts of disodium hydrogen phosphate and 100 parts of water, and add 10 parts of urea to make a mixed solution, adjust the pH to 5, and heat to 30°C;

[0047](2) Convey 180 parts of rice starch into the air conveyor with hot air at 50°C, and use a sprayer to spray the heated orthophosphate mixed solution into a mist at the front end 1 / 3 of the air conveyor. Fully mixed with starch in the conveyor;

[0048] (3) The mixture of starch and orthophosphate mixed solution coming out of the air conveyor directly enters a fluidized bed reactor, and is heated and reacted at 140° C. for 3 hours;

[0049] (4) After the reaction, the reactants were washed, and then air-dried or vacuum-dried at 50° C. for 24 hours to obtain a rice starch phosphate monoester with a substitution degree of 0.015.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com