Lower vehicle body rear frame assembly

A rear and frame technology, which is applied in the field of rear frame components of the lower body, can solve the problems of discontinuous cavity, limited force, performance defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

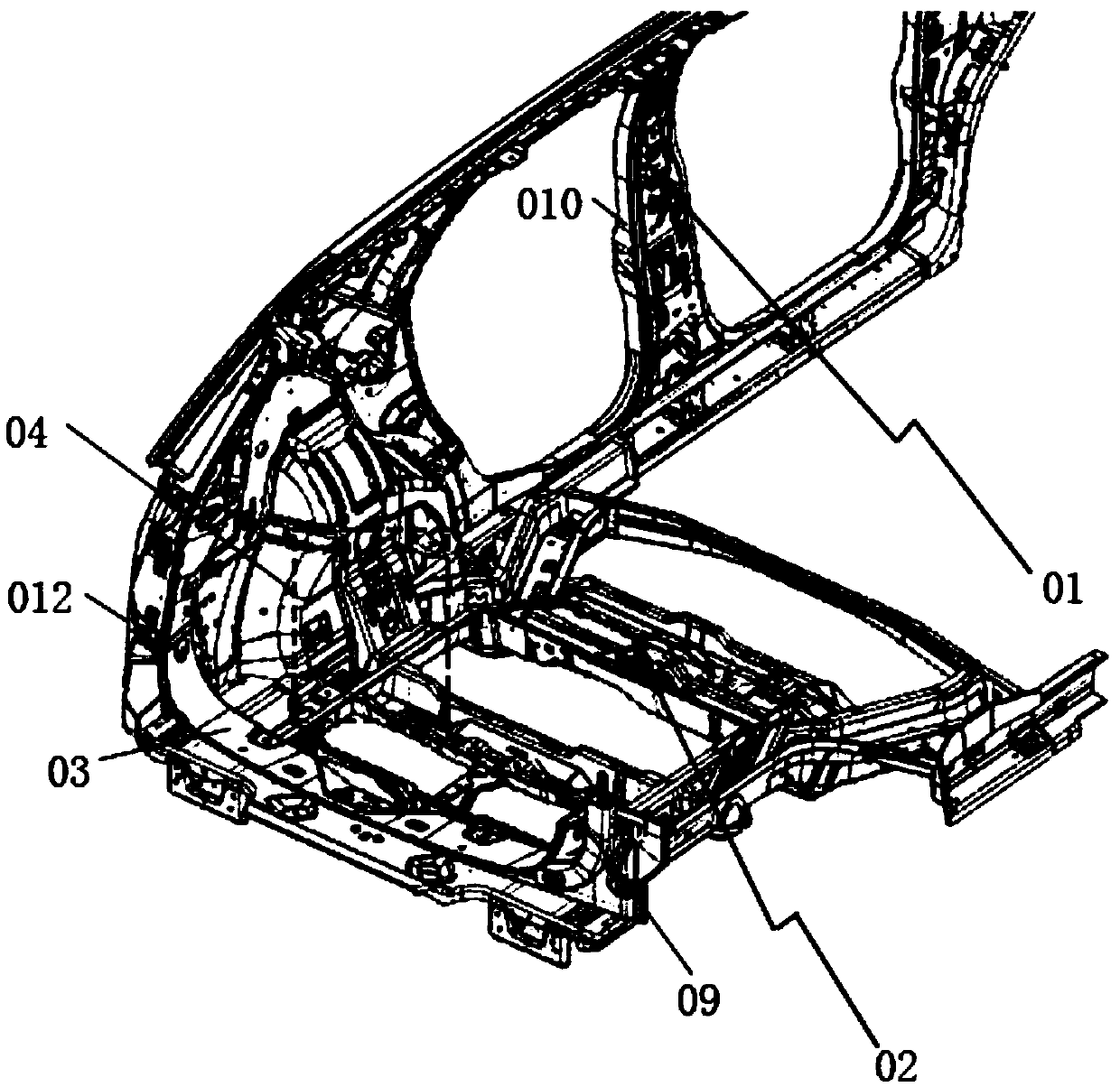

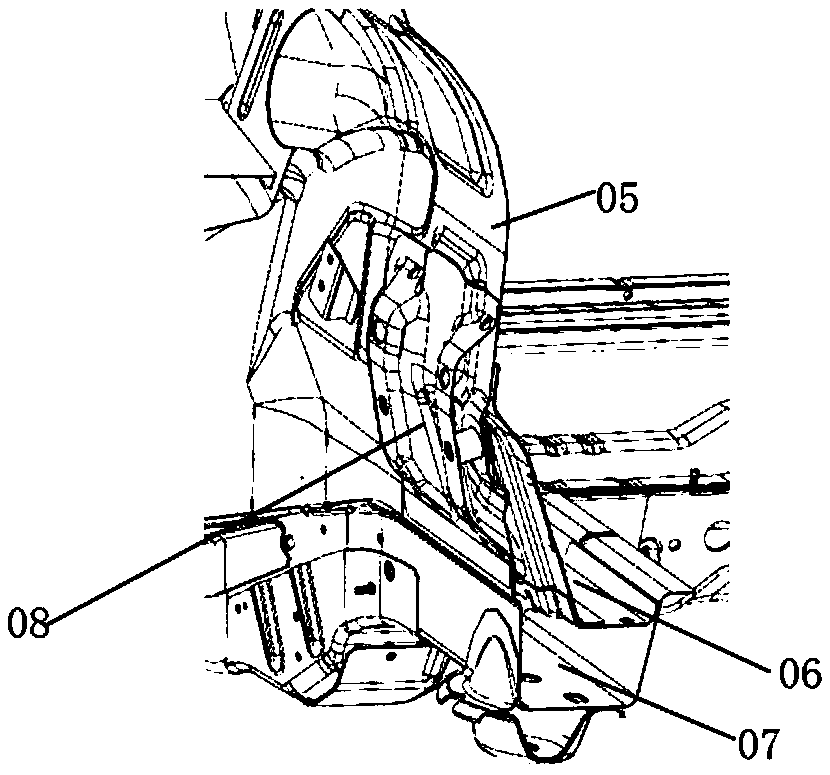

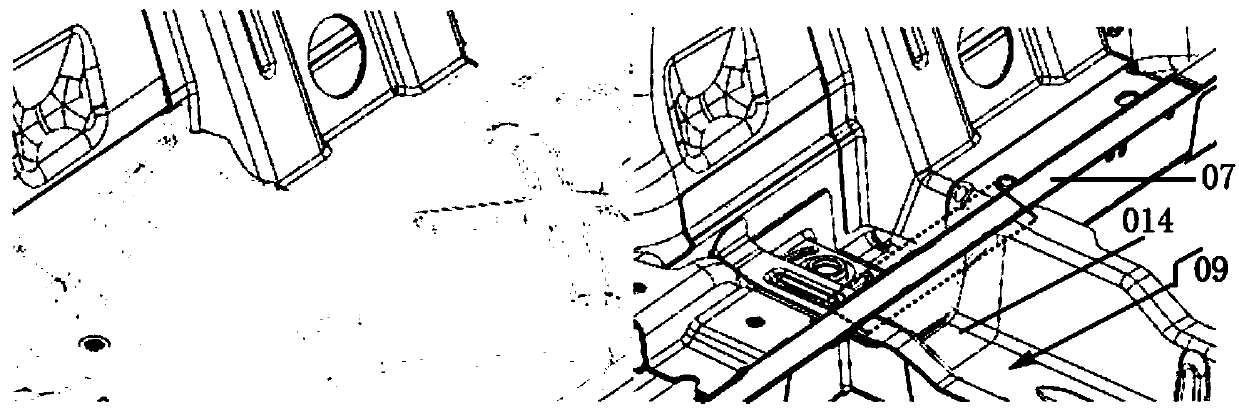

[0042] Below in conjunction with the attached drawings Figure 4 to Figure 9 A further detailed description of the rear frame assembly of the lower vehicle body of the present invention.

[0043] The rear frame assembly of the lower car body of the present invention, please refer to Figure 4 to Figure 9 As shown, it includes a wheel cover support plate 2, a rear frame partition 1, a rear frame assembly 3, the longitudinal section of the rear frame partition 1 is n-shaped, and the longitudinal section of the wheel cover support plate 2 is L-shaped. The longitudinal section of the rear frame assembly 3 is U-shaped, the rear frame partition 1 includes two first vertical walls 4 and a first horizontal wall 5, and the two first vertical walls 4 are respectively fixed on the first The left and right ends of a horizontal wall 5, the bottom walls of the two first vertical walls 4 are respectively fixedly connected with the bottom wall of the rear frame assembly 3, and the front and rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com