High-speed rail overhead line system cantilever automatic installation equipment and installation method

An automatic installation and catenary technology, applied in the direction of overhead lines, etc., can solve the problems of large number of tool personnel, low degree of standardization, long working hours, etc., achieve high level of mechanization, save labor, and improve the effect of assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0070] The present invention designs a wrist-arm integral mechanized installation device for the installation of the wrist-arm, so as to improve the mechanization level of the installation of the wrist-arm, reduce manpower, and improve construction accuracy.

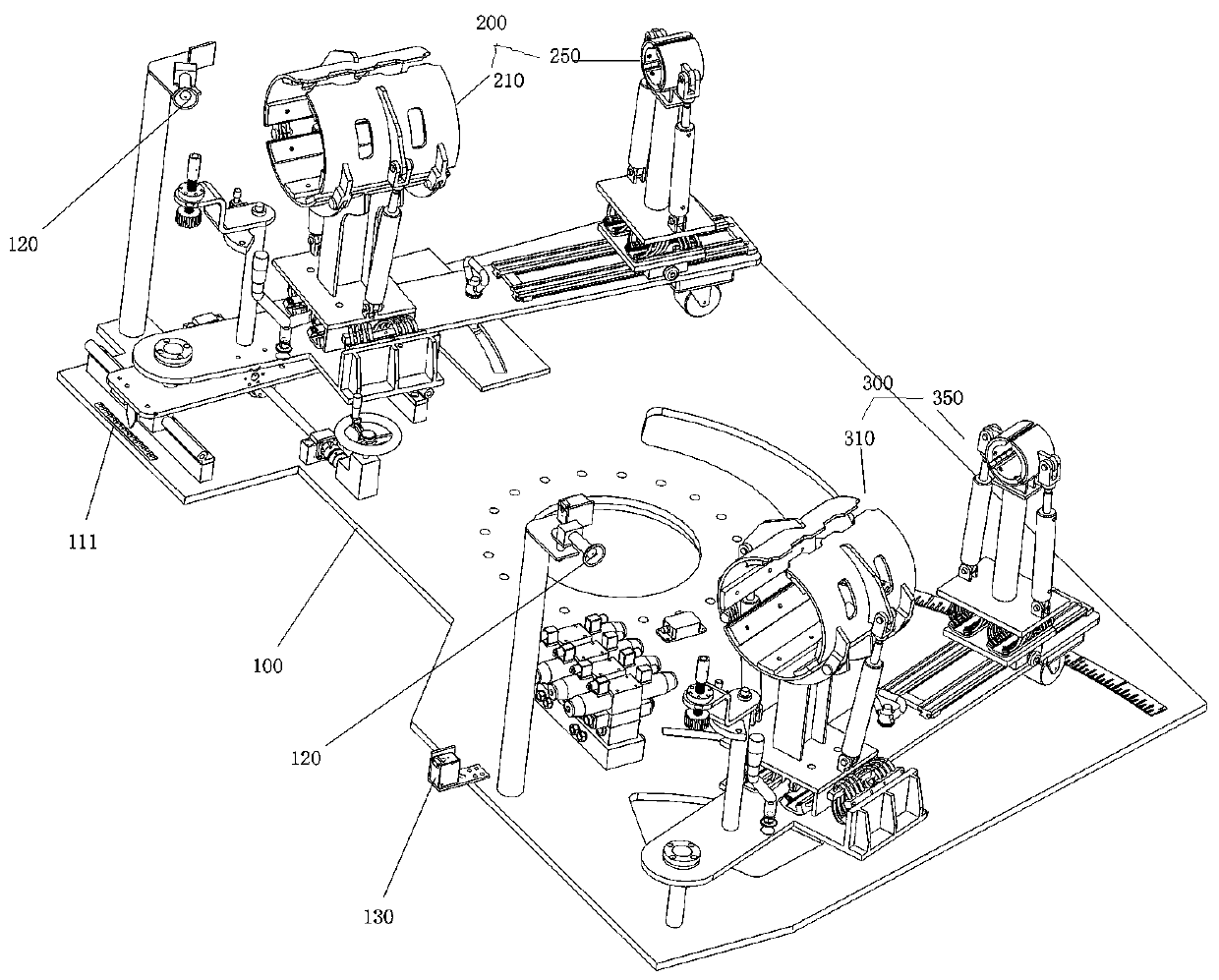

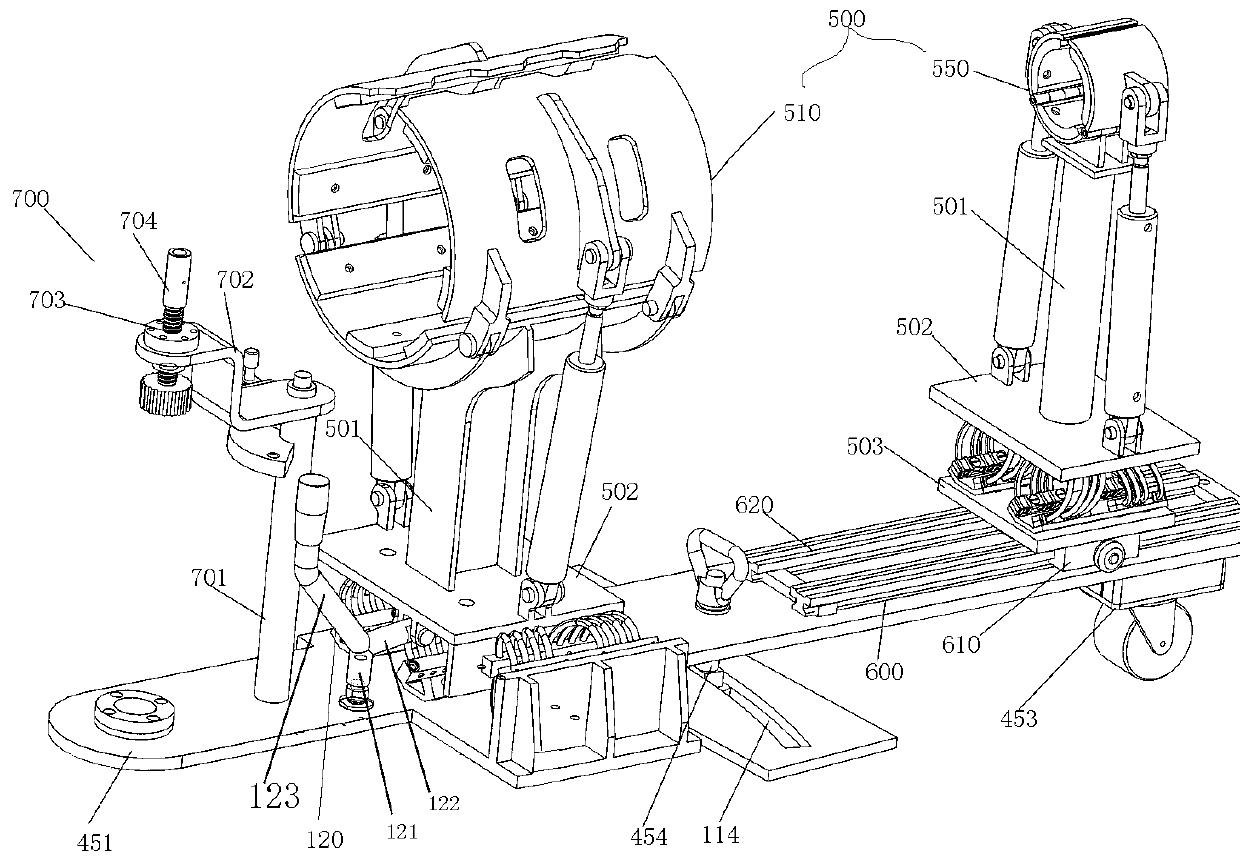

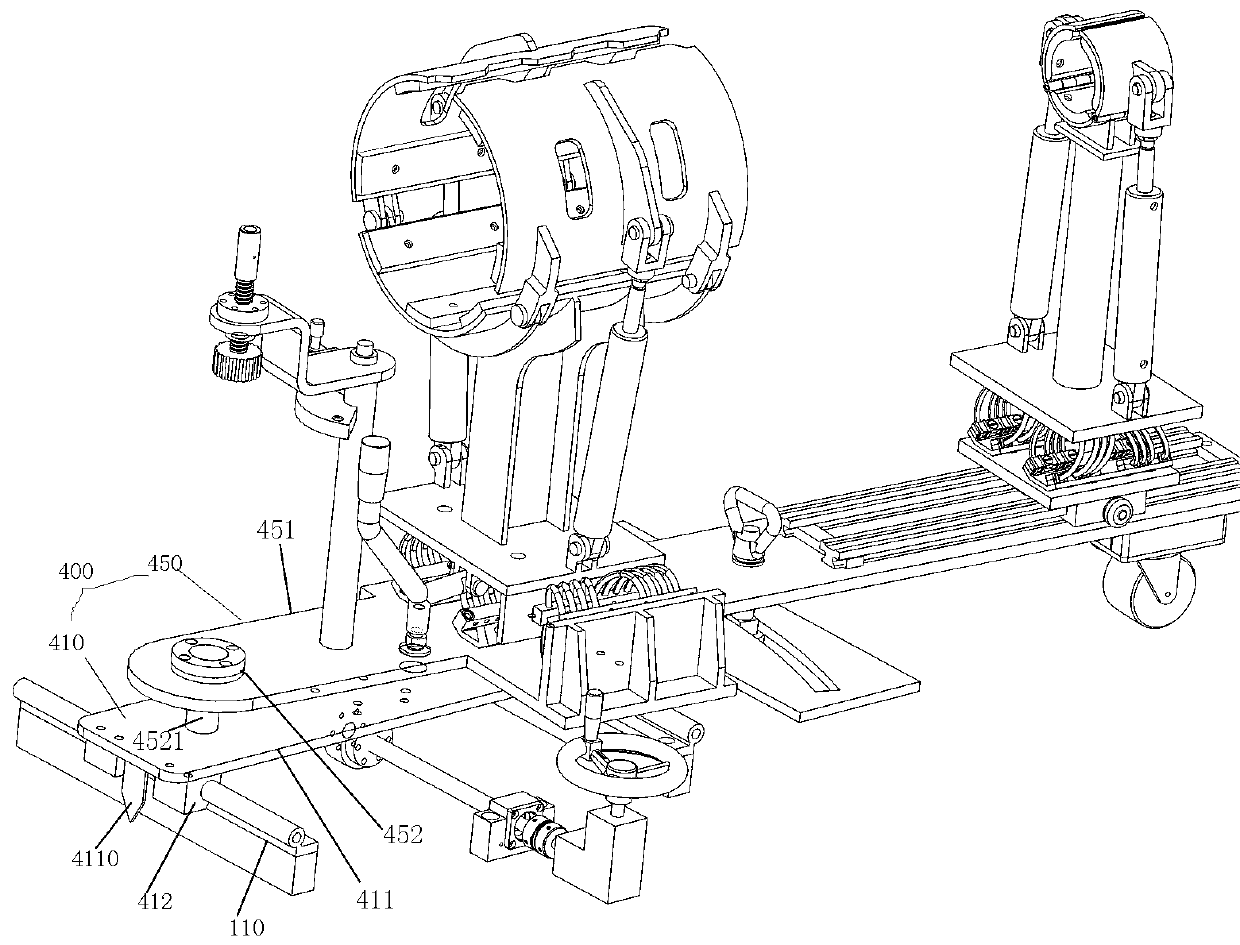

[0071] The technical scheme of the present invention divides the operation into two main operation items: ① using the assembly template to complete the assembly of the wrist arm on site; ② precise alignment and installation of the wrist arm and the pillar. The main equipment is: wrist arm assembly formwork, hoisting alignment mechanical arm. The auxiliary equipment is the aerial work vehicle 910, and the hoisting and alignment mechanical arm can be installed on the aerial work vehicle, or special mechanical arm equipment can be used. The aerial work vehicle 910 can transport th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com