Test method and device for acquiring steam curing parameters of prefabricated part at low temperature and steam curing method

A prefabricated component and parameter acquisition technology, applied in manufacturing tools, ceramic molding machines, etc., can solve problems such as uncontrollable temperature, large steam loss, quality problems, etc., to improve mold turnover rate, better product quality, and reduce steam curing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The present invention is carried out in conjunction with the production line of the fixed mold table, the temperature probe is placed in the curing shed, and the temperature is controlled by an automatic temperature control valve;

[0050] The concrete mix ratio was fixed throughout the test;

[0051] Steam curing is divided into four stages: static stop stage, heating stage, constant temperature stage, and cooling stage

[0052] When the mold entry temperature is 5°C, the static stop temperature is calculated 4 hours from the completion of concrete pouring, and the static stop temperature is 20°C.

[0053] In the heating stage, the heating rate is 20°C / h, and the heating time is 1 hour

[0054] The constant temperature is 40°C, and the constant temperature time is 4h;

[0055] The cooling rate is 10°C / h, and the cooling time is 3.5 hours.

[0056] The curing time for the whole stage from static stop to cooling is 12.5h.

[0057] The heating rate is controlled by sett...

Embodiment 2

[0060] When the mold entry temperature is 10°C, the static stop temperature is calculated for 5 hours from the completion of concrete pouring, and the static stop temperature is 30°C.

[0061] The constant temperature is 30°C, and the constant temperature time is 4h;

[0062] The cooling rate is 10°C / h, and the cooling time is 2.5 hours.

[0063] The curing time for the whole stage from static stop to cooling is 11.5h.

[0064] It has been verified that after 11.5 hours of steam curing, the demoulding strength is 22.6Mpa, which meets the mold release strength, and the quality of the components is good. After the steam curing is transferred to the standard curing, the 3d strength is 38.2, and the 7d age strength is 44.4Mpa. The law of strength growth does not affect the growth of strength in the later stage.

Embodiment 3

[0066] When the mold entry temperature is 15°C, the static stop temperature is calculated 4 hours from the completion of concrete pouring, and the static stop temperature is 30°C.

[0067] The constant temperature is 50℃, and the constant temperature time is 3h;

[0068] The cooling rate is 10°C / h, and the cooling time is 4.5 hours.

[0069] The curing time for the whole stage from static stop to cooling is 12h.

[0070] It has been verified that after 12 hours of steam curing, the demoulding strength is 26.6Mpa, which meets the mold release strength, and the quality of the components is good. After the steam curing is transferred to the standard curing, the 3d strength is 34.2, and the 7d age strength is 39.2Mpa. The law of strength growth does not affect the growth of strength in the later stage.

[0071]

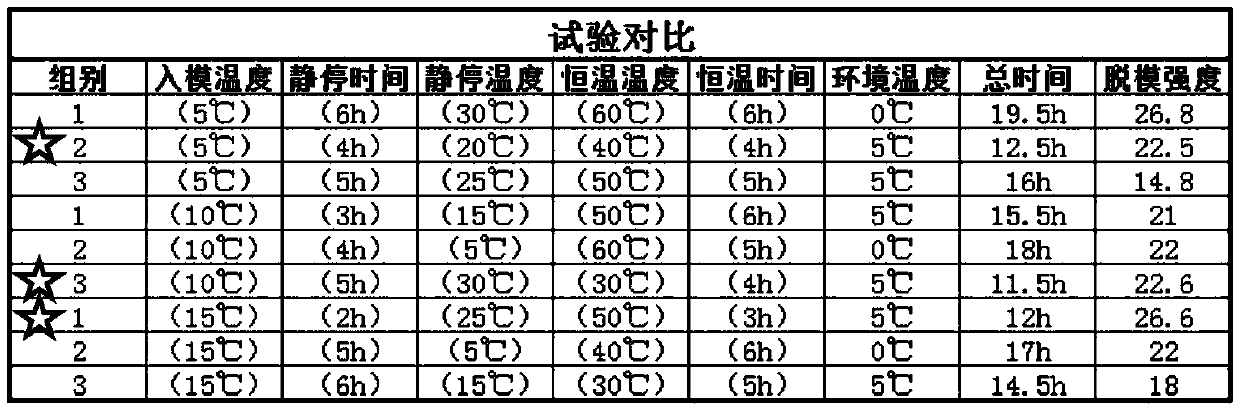

[0072] As can be seen from the comparison in the above table, it can be seen that the ejection strength of prefabricated components that meets the specification requ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com