Method for degrading naphthalene in soil through combination of microwave induction and catalytic oxidation

A technology of synergistic catalysis and oxidative degradation, applied in the field of environmental organic pollutants remediation, can solve the problems of being easily restricted by environmental factors and climatic conditions, the long-term restoration period of bioremediation methods, and the inability to achieve restoration effects, so as to promote oxidative decomposition. ability, improve mineralization and decomposition ability, and the effect of fast oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

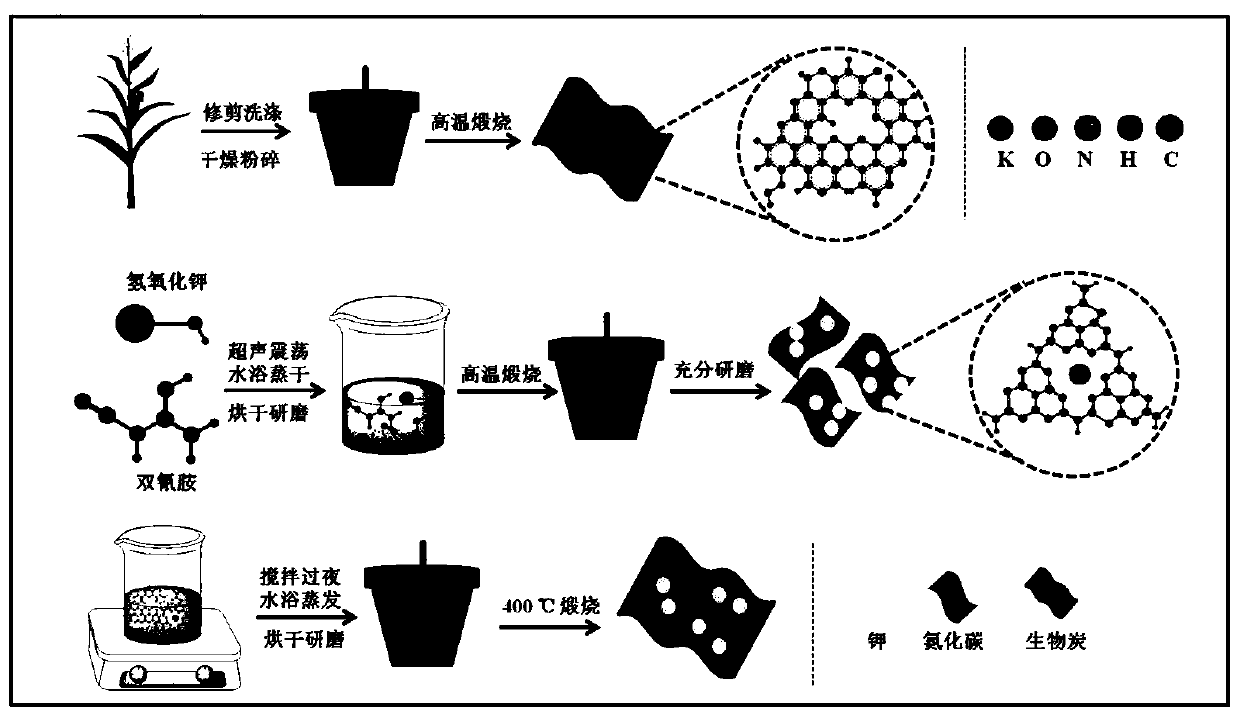

Method used

Image

Examples

Embodiment 1

[0038] Take uncontaminated fresh soil samples, add 50mL of ethanol solution with a concentration of 1mg / L naphthalene (preparation of ethanol stock solution of 100mg / L naphthalene, and then dilute it to 1mg / L), stir well, and place in a fume hood The ethanol solution was volatilized cleanly, and then passed through a 2mm sieve to ensure that the soil was uniformly contaminated, and a soil sample contaminated with naphthalene, a polycyclic aromatic hydrocarbon, could be obtained, with a concentration of 10mg / kg.

[0039] Weigh 5g of the above uniformly poisoned soil samples, add 50mg of biochar, carbon nitride, potassium-doped carbon nitride, and biochar-loaded potassium-doped carbon nitride, then add 1g of distilled water, mix well and put in poly In the vinyl fluoride reactor, put it in a microwave digestion apparatus for degradation. The microwave treatment time is 2min, 4min, 6min, 8min, 10min respectively, the microwave frequency is 2450MHz, the output power is 400-700W, an...

Embodiment 2

[0042] Take uncontaminated fresh soil samples, add 50mL of ethanol solution with a concentration of 1mg / L naphthalene (preparation of ethanol stock solution of 100mg / L naphthalene, and then dilute it to 1mg / L), stir well, and place in a fume hood The ethanol solution was volatilized cleanly, and then passed through a 2mm sieve to ensure that the soil was uniformly contaminated, and a soil sample contaminated with naphthalene, a polycyclic aromatic hydrocarbon, could be obtained, with a concentration of 10mg / kg.

[0043] Weigh 5g of the above uniformly poisoned soil samples, add 10mg of biochar, carbon nitride, potassium-doped carbon nitride, biochar-loaded potassium-doped carbon nitride, and then add 0.6g, 0.7g, 0.8g, 0.9g, 1.0g of distilled water, mix them evenly, put them into a polytetrafluoroethylene reactor, place them in a microwave digestion apparatus for degradation, the microwave treatment time is 8min, the microwave frequency is 2450MHz, the output power is 400-700W, ...

Embodiment 3

[0046] Take uncontaminated fresh soil samples, add 50mL of ethanol solution with a concentration of 1mg / L naphthalene (preparation of ethanol stock solution of 100mg / L naphthalene, and then dilute it to 1mg / L), stir well, and place in a fume hood The ethanol solution was volatilized cleanly, and then passed through a 2mm sieve to ensure that the soil was uniformly contaminated, and a soil sample contaminated with naphthalene, a polycyclic aromatic hydrocarbon, could be obtained, with a concentration of 10mg / kg.

[0047] Weigh 5g of the above uniformly poisoned soil samples, add biochar, carbon nitride, potassium-doped carbon nitride, and biochar-supported potassium-doped carbon nitride catalysts, respectively, and add 10mg, 20mg, 30mg, 40mg, 50mg, add 0.6g distilled water to each sample, mix evenly, put it into a polytetrafluoroethylene reactor, and place it in a microwave digestion apparatus for degradation. The microwave treatment time is 8min respectively, and the microwave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com