Assembled power distribution cabinet

A power distribution cabinet and assembled technology, which is applied in substation/power distribution device housing, electrical components, substation/switch layout details, etc., can solve the problems of difficult to ensure the personal safety of staff, difficulties in dust removal or maintenance process, and large side panels and other problems, to achieve the effect of convenient manufacturing and transportation, convenient modular installation, and increased operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

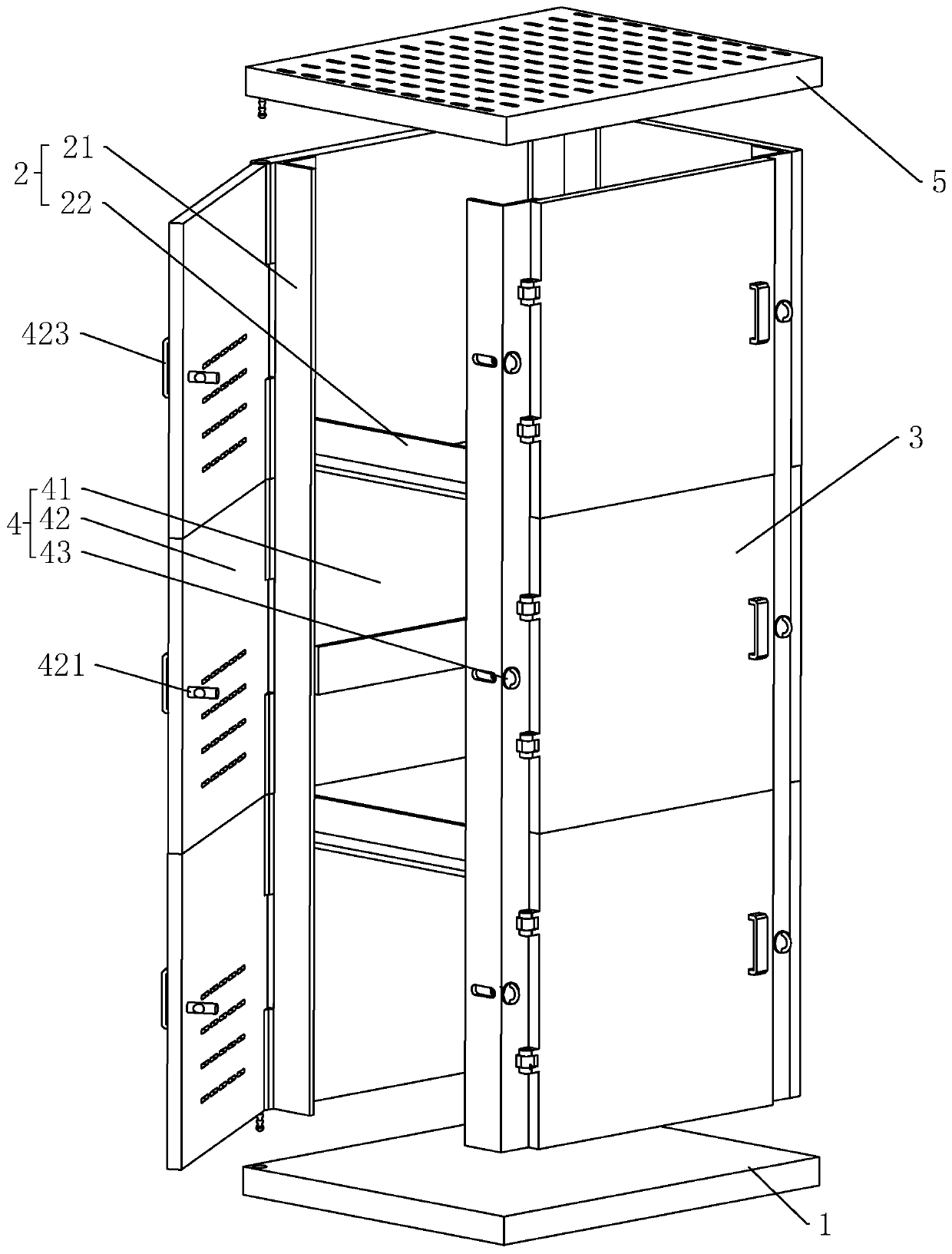

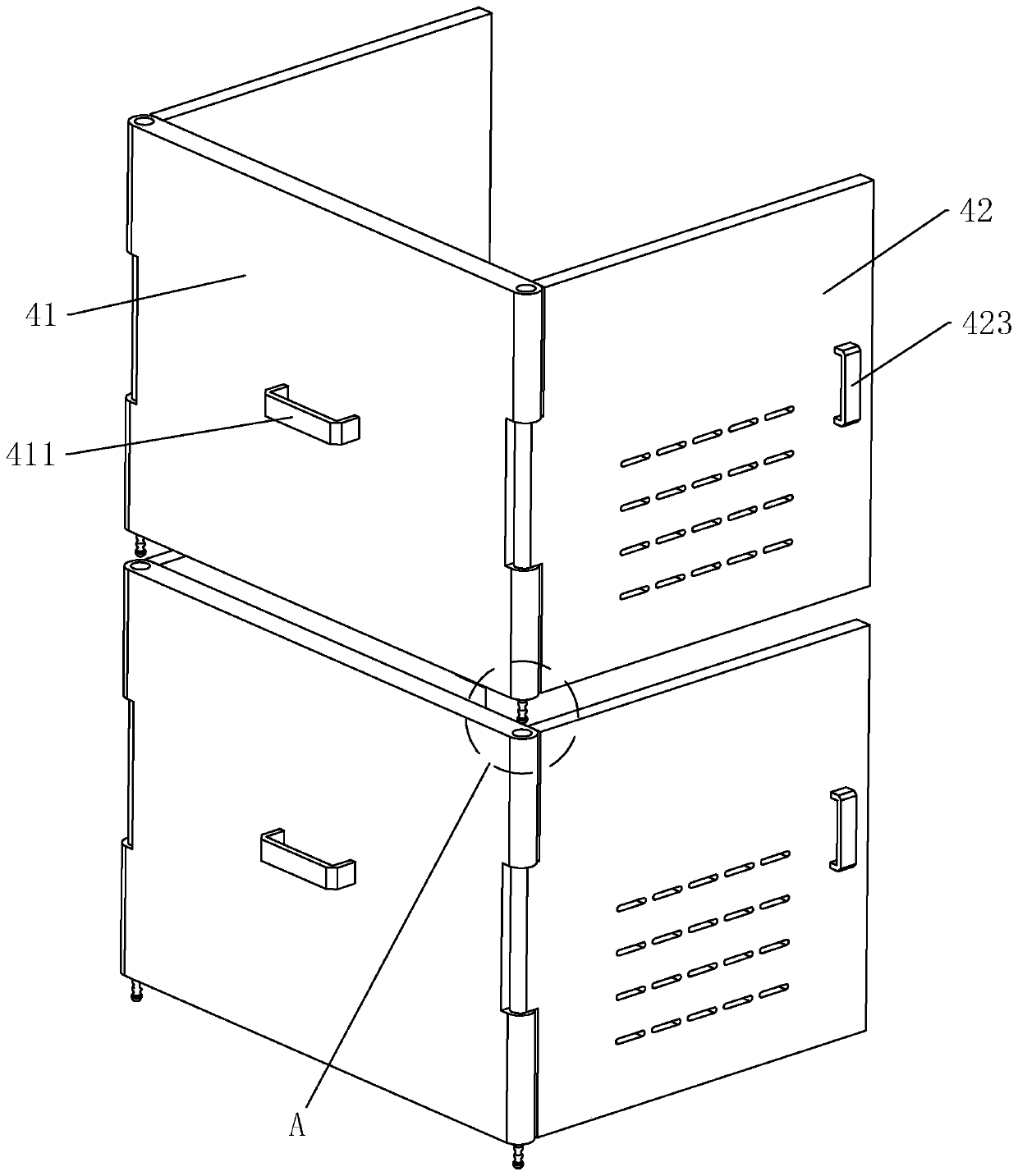

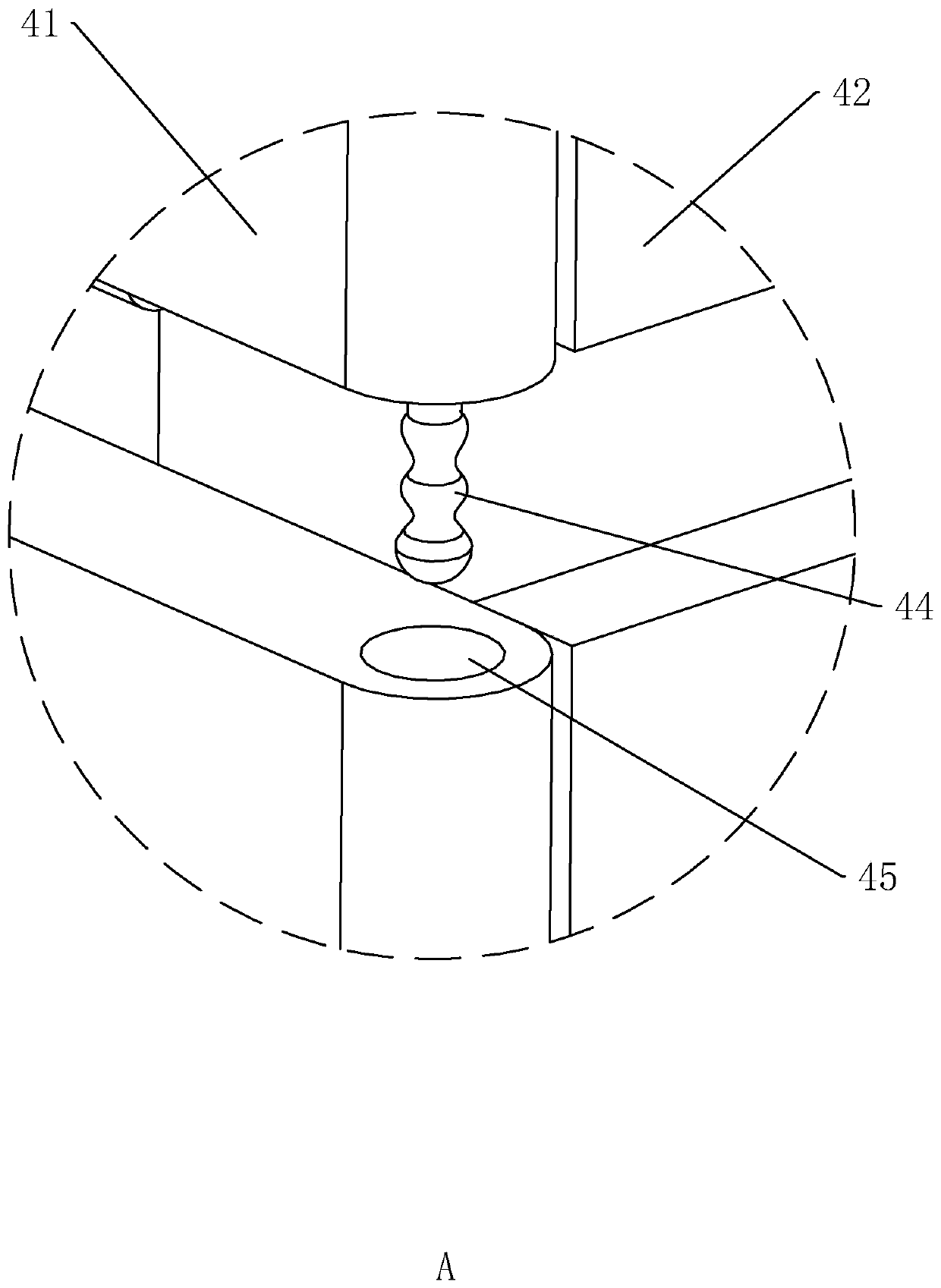

[0044] refer to figure 1 with figure 2 , is a combined power distribution cabinet disclosed in the embodiment of the present invention, including a bottom plate 1, a steel frame 2, a cabinet door 3, several assembly units 4 and a top plate 5, and the steel frame 2 includes four vertical and fixedly connected to the bottom plate 1. A vertical angle steel 21 and a plurality of horizontal angle steels 22 fixedly connected between adjacent vertical angle steels 21, four vertical angle steels 21 surround and form a square area, and the horizontal angle steels 22 are used for installing and carrying electrical components; the cabinet door 3 Hinged between two vertical angles 21; each group of assembled units 4 includes a first side plate 41 opposite to the cabinet door 3, and a second side plate 42 hinged on the opposite sides of the first side plate 41 And the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com