Novel vertical-axis wind driven generator and assembly method thereof

A technology of wind power generators and assembly methods, which is applied to the combination of wind power generators, the assembly of wind power engines, wind power engines, etc., and can solve the problems of difficult assembly of wind power generators, time-consuming and labor-intensive repairs and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

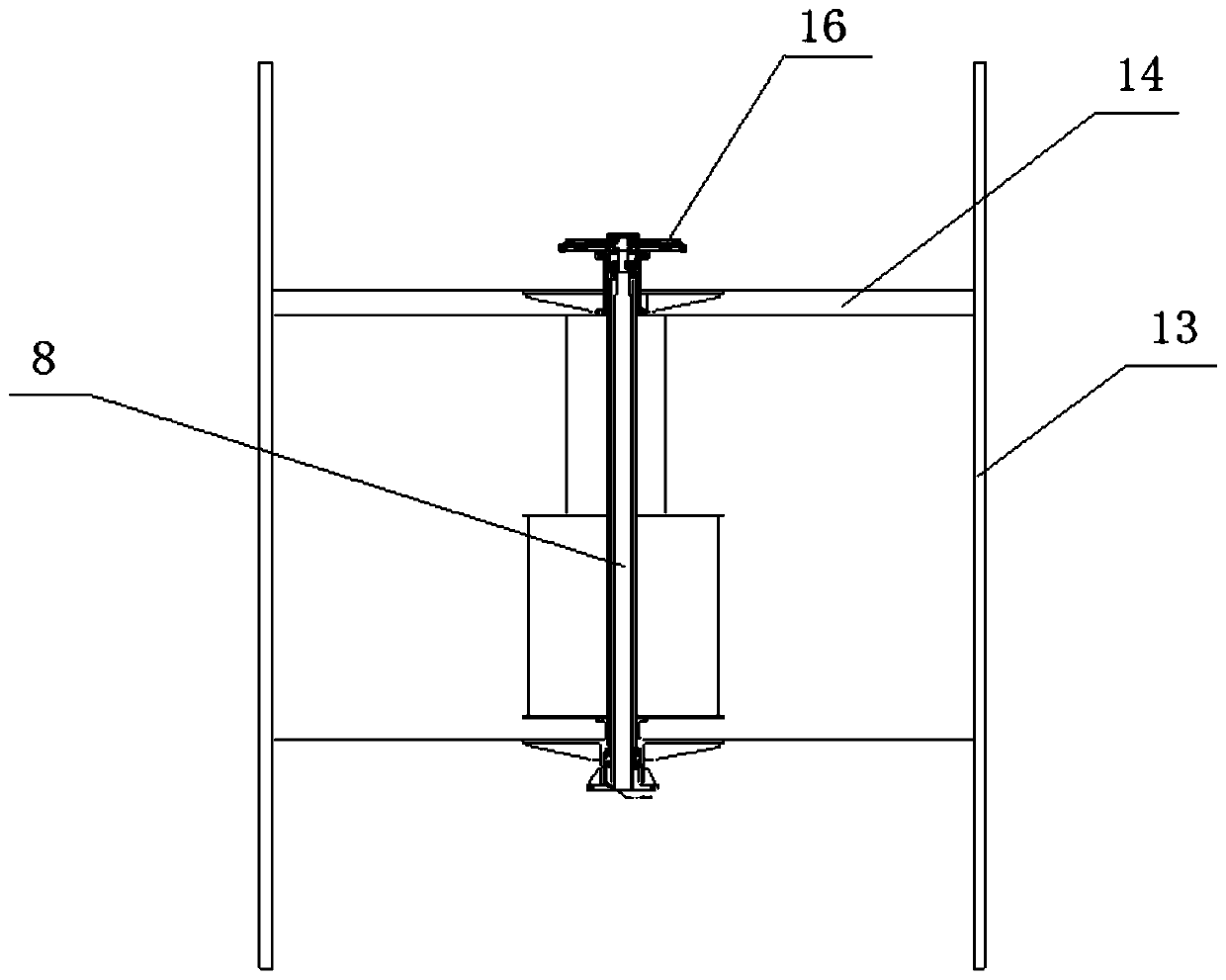

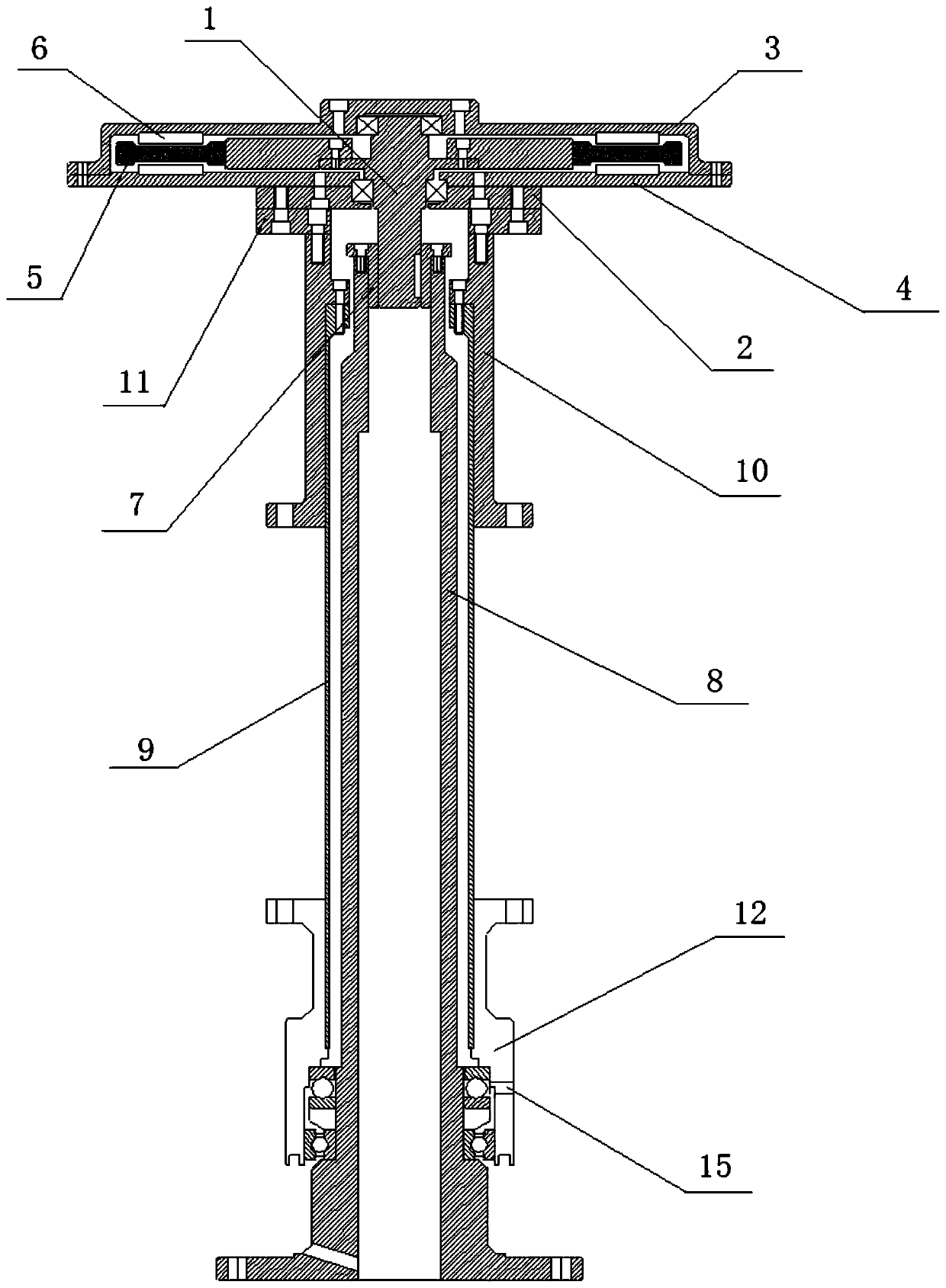

[0032] Such as figure 1 and figure 2 As shown, a novel vertical axis wind power generator includes a magnetic levitation generator assembly 16, the motor shaft 1 of the magnetic levitation generator assembly 16 is connected to the fan shaft 8 through the motor shaft adapter sleeve 7, and the fan shaft 8 is rotatably fitted with a fan barrel 9, the upper end of the fan barrel 9 is equipped with a bracket upper support sleeve 10, the lower end of the fan barrel 9 is equipped with a bracket lower support sleeve 12, and the support upper support sleeve 10 passes through the The connecting flange 11 is connected with the motor bearing cover 2 below the magnetic levitation generator assembly 16 , and the fan blade 13 is installed on the upper support sleeve 10 and the lower support sleeve 12 of the support through the support 14 .

[0033] During use, fan blade 13 is driven by the wind force, drives blower cylinder body 9 through support 14 and the shell of magnetic levitation gen...

Embodiment 2

[0039] A method for assembling a novel vertical axis wind power generator, comprising the steps of:

[0040] (1) Place the main shaft of the fan 8 vertically, support the sleeve 12 and the barrel of the fan 9 under the set bracket;

[0041] (2) Fan blade 13 is installed on the support 14;

[0042] (3) Continue to install the upper support sleeve 10 on the fan barrel 9;

[0043] (4) Install the support 14 with the fan blade 13 installed on the upper support sleeve 10 of the support and the lower support sleeve 12 of the support;

[0044] (5) Install the motor shaft adapter sleeve 7 on the fan shaft 8;

[0045] (6) Install the connecting flange 11 on the support sleeve 10 on the bracket;

[0046] (7) Finally, put the magnetic levitation generator assembly 16 into it.

[0047] Before the actual assembly, each part can be cleaned with diesel oil, which can remove impurities on the surface of the parts and play a good role in lubrication, which is convenient for subsequent asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com