Suspended self-support type piling method and piling machine

A self-supporting, piling machine technology, applied in the direction of sheet pile walls, buildings, infrastructure engineering, etc., can solve the problem that the bridge erecting machine cannot guarantee to provide a stable support position, cannot complete the piling operation of heavy prefabricated piles, travel and load limitations, etc. problems, achieve the effect of lifting stroke and load, saving construction cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

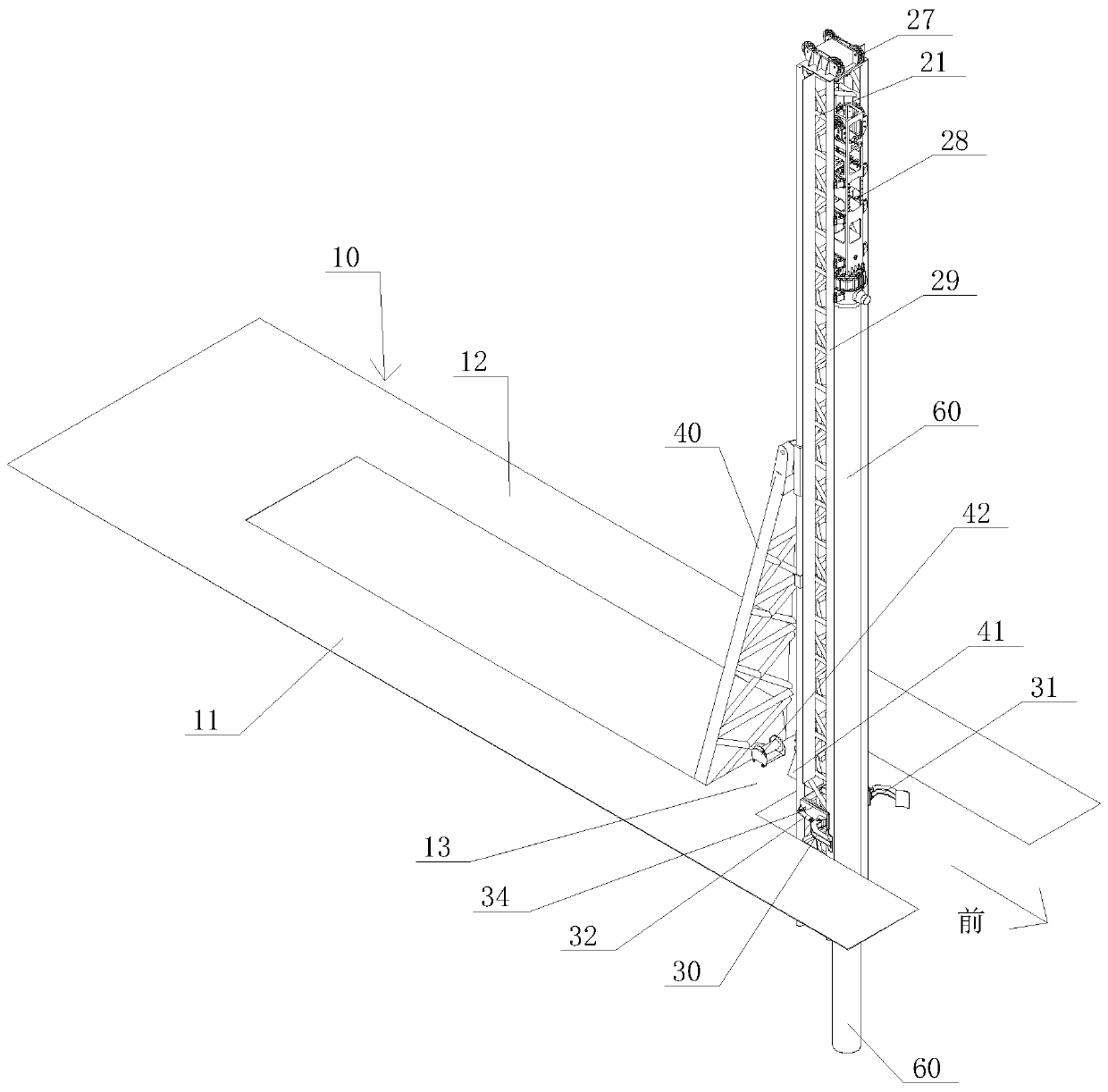

[0075] Embodiment 1: The suspended self-supporting piling method provided by this embodiment comprises the following steps:

[0076] (1), the first girder 11 and the second girder 12 of the bridge erecting mechanism 10 are stretched forward, so that the front end support link beam 13 of the bridge erecting mechanism 10 is suspended above the pile foundation to be constructed;

[0077] (2), utilize bridging mechanism 10 to be installed prefabricated pile 60 horizontally on the front side of piling mechanism 20 column pylons 21, and the prefabricated pile 60 to be constructed is fixed with column pylon 21;

[0078] (3), start the luffing hoist 42, tighten the luffing wire rope 421 of the luffing hoist 42, shorten the distance between the first pulley 471 and the second pulley 472 of the luffing pulley group 47, and change the support frame 45 and bridging accordingly The triangular dimensional relationship between the mechanism 10 and the column tower 21 realizes the variable am...

Embodiment 2

[0090] The suspended self-supporting piling method provided by this embodiment is basically the same as that of Embodiment 1, except that:

[0091] Described step 1 (before step 2) also comprises the following steps:

[0092] The prefabricated pile 60 to be constructed is transported to the second half of the bridge erecting mechanism 10, and is located between the first main girder 11 and the second main girder 12, wherein the bridge erecting mechanism 10 includes the first half and the rear half, and the piling mechanism 20 is located at first half;

[0093] Start the first crane crane 151 and the second crane crane 152, and the front end and rear end of the prefabricated pile 60 to be constructed are hoisted on the first crane crane 151 and the second crane crane 152 respectively;

[0094] Simultaneously move the first lifting crane 151 and the second lifting crane 152, and move the first lifting crane 151 and the second lifting crane 152 to the first half of the bridging ...

Embodiment 3

[0098] The suspended self-supporting piling method provided by this embodiment is basically the same as that of Embodiment 1 and 2, except that:

[0099] Installing the prefabricated pile 60 to be constructed on the column tower 21 of the piling mechanism 20 also includes the following steps:

[0100] When the prefabricated pile 60 to be constructed is placed on the front side of the column tower 21, the first clamping oil cylinder 32 and the second clamping oil cylinder 33 are started, and the first clamping oil cylinder 32 and the second clamping oil cylinder 33 are extended to drive The first clamping arm 30 and the second clamping arm 31 clamp the prefabricated pile 60 to be constructed, and clamp and fix the prefabricated pile 60 to be constructed and the front side of the column tower 21 .

[0101] A suspended self-supporting pile driver implementing the above piling method, which includes a bridging mechanism 10, a piling mechanism 20, a folding mechanism 40, and the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com