Microcrystalline glass taking coal cinder as main raw material and preparation method thereof

A technology for glass-ceramic and main raw materials, applied in the field of glass-ceramic and its preparation, can solve the problems of preparing glass-ceramic and less coal slag, and achieve the effects of promoting crystal precipitation, easy melting, and reducing crystallization activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

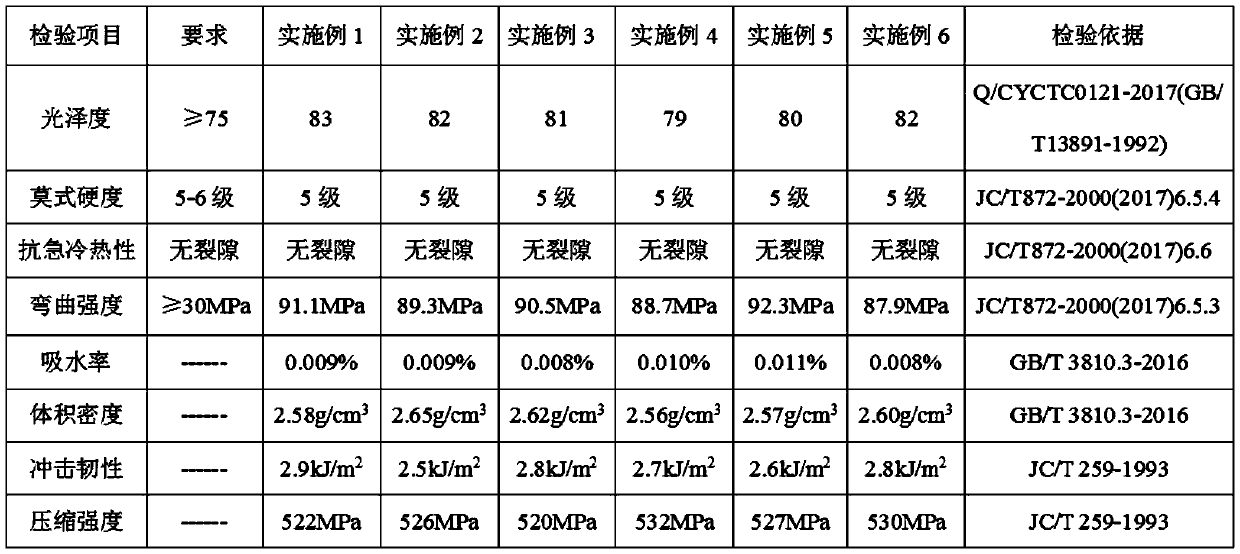

Examples

preparation example Construction

[0025] The preparation method of the glass-ceramic with coal slag as the main raw material comprises the following steps:

[0026] S1: Weigh cinder, quartz sand, dolomite, calcite, soda ash, borax, barium carbonate, zirconia, titanium powder, and sulfur in proportion, and mix them uniformly to obtain batch materials;

[0027] S2: Melt the batch material obtained in step A at a temperature of 1550-1600°C in a melting furnace to obtain molten glass, lower the temperature of the melted molten glass to 1100-1150°C, and then enter the calender for compression molding to obtain base glass;

[0028] S3: Send the obtained basic glass into a crystallization furnace, undergo nucleation, crystallization, and annealing treatments, wherein the nucleation temperature is 700-750°C, the nucleation time is 2 hours, the crystallization temperature is 880-930°C, The melting time is 3 hours, the annealing temperature is 800-850° C., and then the finished glass-ceramic is obtained through cutting...

Embodiment 1

[0030] A glass-ceramic with cinder as the main raw material, comprising the following raw materials by weight percentage: 54.5% of cinder, 13.2% of quartz sand, 8.8% of dolomite, 9.7% of calcite, 7.0% of soda ash, 3.5% of borax, and 2.5% of barium carbonate , zirconia 0.4%, titanium powder 0.2%, sulfur 0.2%.

[0031] The preparation method of the glass-ceramic with coal slag as the main raw material comprises the following steps:

[0032]S1: Weigh cinder, quartz sand, dolomite, calcite, soda ash, borax, barium carbonate, zirconia, titanium powder, and sulfur in proportion, and mix them uniformly to obtain batch materials;

[0033] S2: Melting the batch material obtained in step A at a temperature of 1550°C in a melting furnace to obtain molten glass, lowering the temperature of the melted molten glass to 1120°C, and then entering the calender for compression molding to obtain the basic glass;

[0034] S3: Send the obtained basic glass into a crystallization furnace, undergo n...

Embodiment 2

[0036] A glass-ceramic with cinder as the main raw material, comprising the following raw materials by weight percentage: 56.3% cinder, 12% quartz sand, 9% dolomite, 8% calcite, 9% soda ash, 2% borax, and 2.8% barium carbonate , zirconia 0.5%, titanium powder 0.1%, sulfur 0.3%.

[0037] The preparation method of the glass-ceramic with coal slag as the main raw material comprises the following steps:

[0038] S1: Weigh cinder, quartz sand, dolomite, calcite, soda ash, borax, barium carbonate, zirconia, titanium powder, and sulfur in proportion, and mix them uniformly to obtain batch materials;

[0039] S2: Melt the batch material obtained in step A at a temperature of 1580°C in a melting furnace to obtain molten glass, lower the temperature of the melted molten glass to 1100°C, and then enter the calender for compression molding to obtain the basic glass;

[0040] S3: Send the obtained basic glass into a crystallization furnace, undergo nucleation, crystallization, and anneali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com