Device and method for preparing optical fiber preform loose body through VAD

A technology of optical fiber preform and loose body, which is applied in the direction of glass manufacturing equipment and manufacturing tools, which can solve the problems of increasing the workload of production personnel, increasing equipment scrapping, and damage to deposition equipment, so as to avoid the problem of stress cracking and improve production stability and productivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

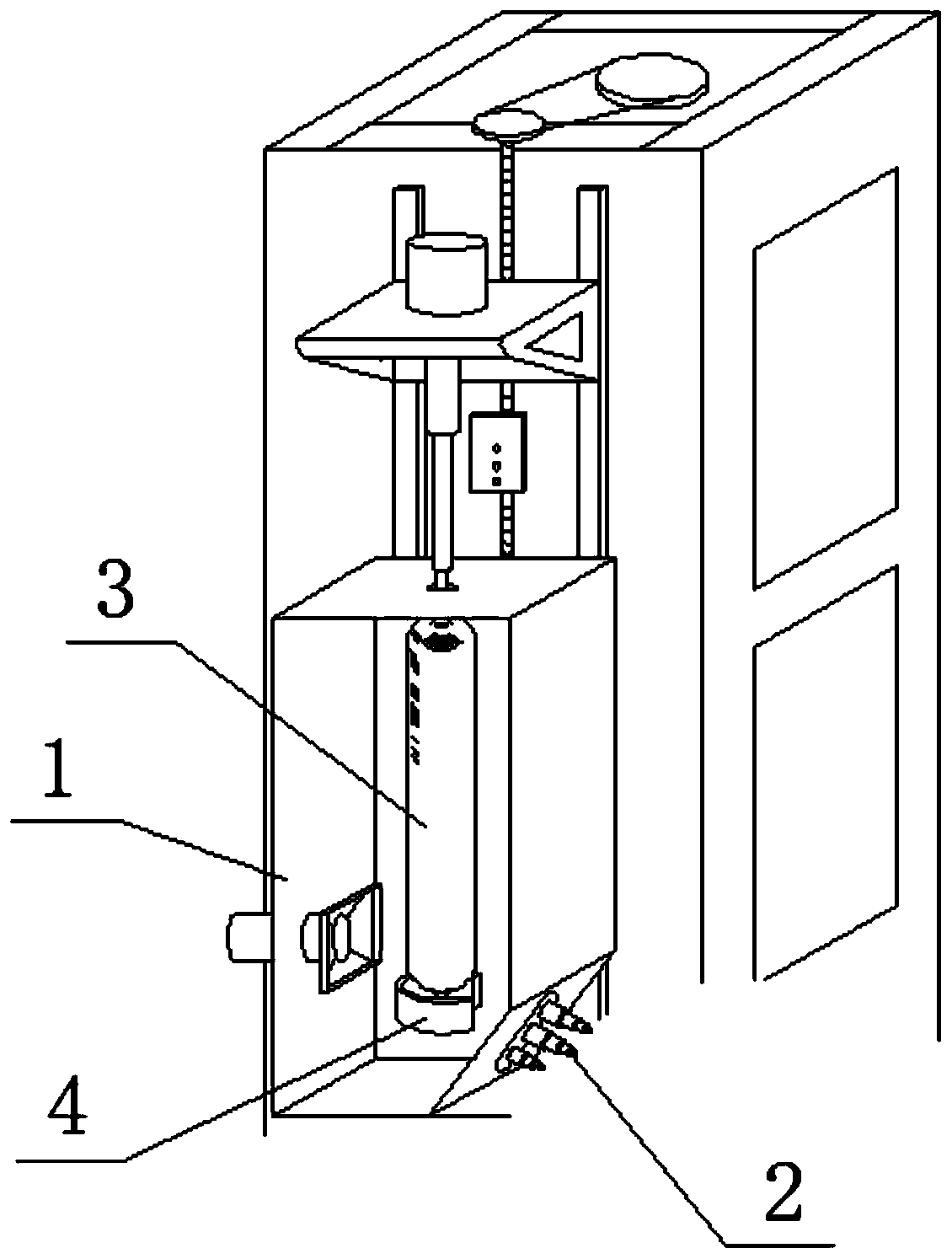

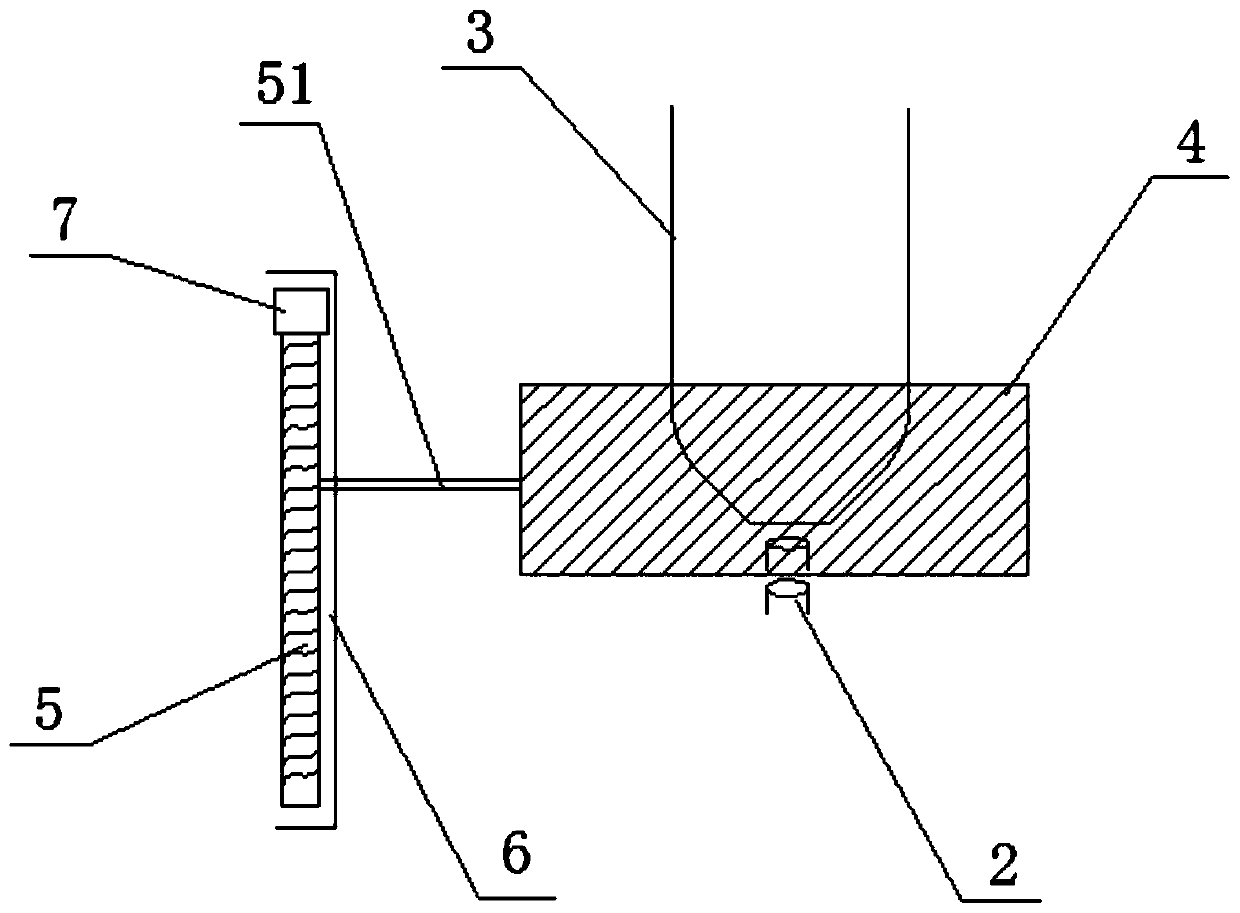

[0034] see figure 1 As shown, the present invention provides an embodiment of a device for preparing a loose optical fiber preform by VAD. The above-mentioned device for preparing a loose optical fiber preform by VAD includes a deposition chamber 1 , a heating ring 4 and a lifting mechanism 5 .

[0035] The interior of the deposition chamber 1 is provided with a torch group 2 , and the nozzles of the torch group 2 are directed towards the bottom high temperature area of the soot preform body 3 . Blowtorch group 2 includes multiple blowtorches, and different flow rates of dopants and SiCl are mixed through different blowtorches 4 Mixed preform loose body deposition is not only very easy to realize the design of the cross-section structure, but also has high production efficiency.

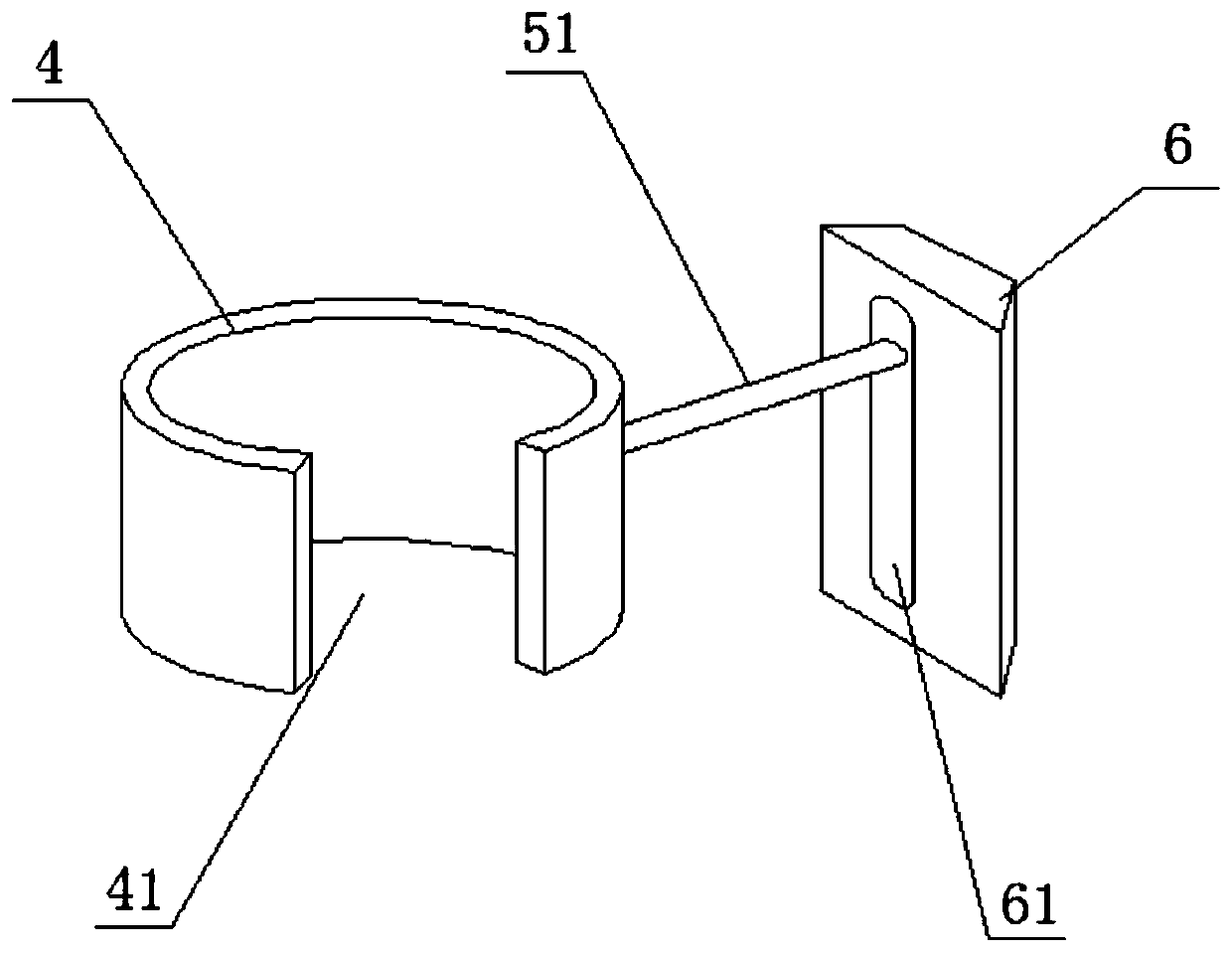

[0036] The heating ring 4 is arranged at the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com