Treatment method and treatment system for methanol-containing high-salinity wastewater

A treatment method and technology for high-salt wastewater, applied in water/sewage treatment, multi-stage water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of difficult high-salt wastewater treatment and large footprint, and achieve operational The effect of low cost, small footprint and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1. Methanol-containing high-salt wastewater treatment system

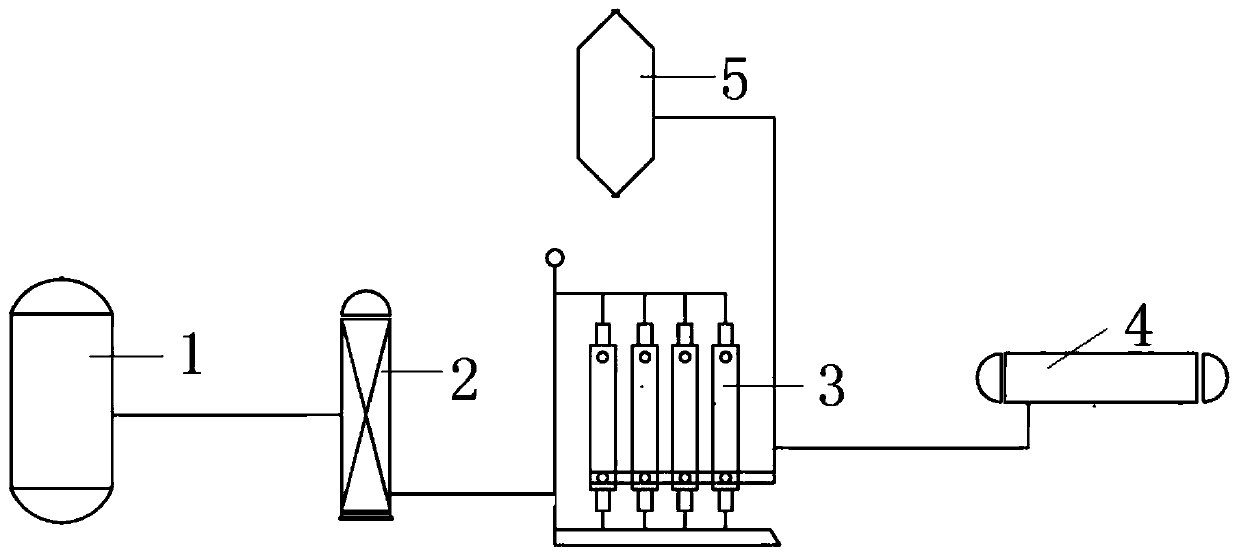

[0032] Such as figure 2 As shown, the methanol-containing high-salt wastewater treatment system of the present invention includes: a primary distillation system 1, an ultrafiltration system 2 connected to the water outlet of the primary distillation system, a nanofiltration system 3 connected to the ultrafiltration system water production tank, and a nanofiltration system connected to the nanofiltration system. The MVR system 4 connected to the concentrated water tank of the system. The nanofiltration water production tank of the nanofiltration system is connected with a secondary distillation system 5 for methanol recovery. All monomer systems are connected by pipelines. Among them, the various inlet and outlet pipelines related to MVR evaporation and two-stage distillation are connected by titanium tubes, while ultrafiltration and nanofiltration systems are connected by stainless steel pipeli...

Embodiment 2

[0038] Embodiment 2, the method for treating methanol-containing high-salt wastewater using the above-mentioned treatment system

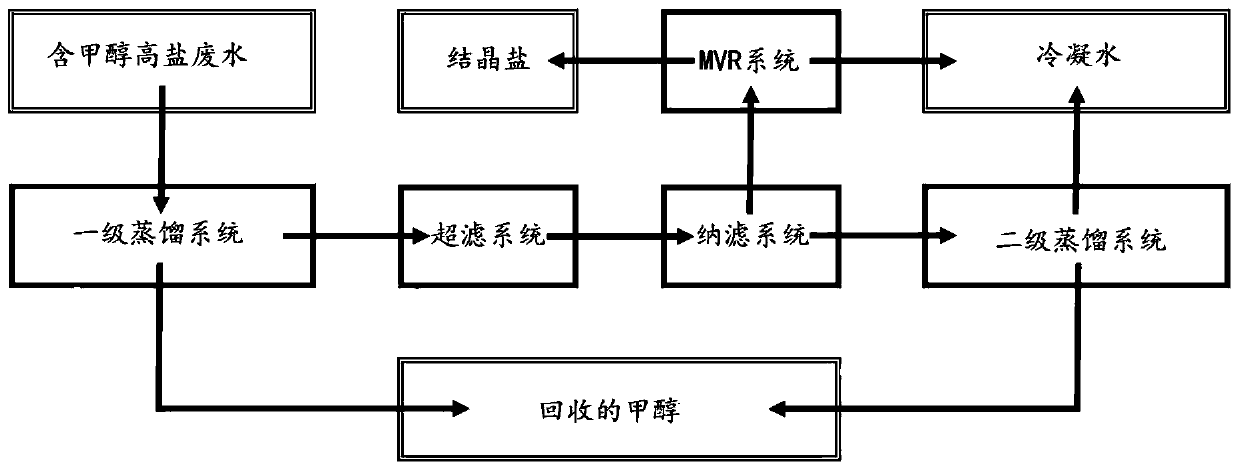

[0039] Process flow diagram as figure 1 , the water quality characteristics of methanol-containing high-salt wastewater in the figure are: total salt concentration 12000mg / L, COD 10000mg / L, the treatment steps are as follows:

[0040] Step 1) Primary distillation: methanol-containing high-salt wastewater enters the primary distillation system for distillation treatment, removes part of the methanol in the wastewater, and obtains primary distillation product water; wherein, the distillation temperature is 75°C, and the distillation time is 120min. The total salt concentration of the produced water is 12000mg / L, and the COD is 40mg / L;

[0041] Step 2) ultrafiltration: the above-mentioned first-stage distilled water is subjected to ultrafiltration through an ultrafiltration system to remove particulate matter to obtain ultrafiltration water; wherein ...

Embodiment 3

[0045] Embodiment 3, the method of using the above-mentioned treatment system to treat methanol-containing high-salt wastewater

[0046] Process flow diagram as figure 1 , the water quality characteristics of methanol-containing high-salt wastewater in the figure are: total salt concentration 8000mg / L, COD 7500mg / L, the treatment steps are as follows:

[0047] Step 1) Primary distillation: methanol-containing high-salt wastewater enters the primary distillation system for distillation treatment, removes part of the methanol in the wastewater, and obtains primary distillation product water; wherein, the distillation temperature is 75°C, and the distillation time is 120min. The total salt concentration of the produced water is 8000mg / L, and the COD is 32mg / L;

[0048] Step 2) ultrafiltration: the above-mentioned first-stage distilled water is subjected to ultrafiltration through an ultrafiltration system to remove particulate matter to obtain ultrafiltration water; wherein the ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com