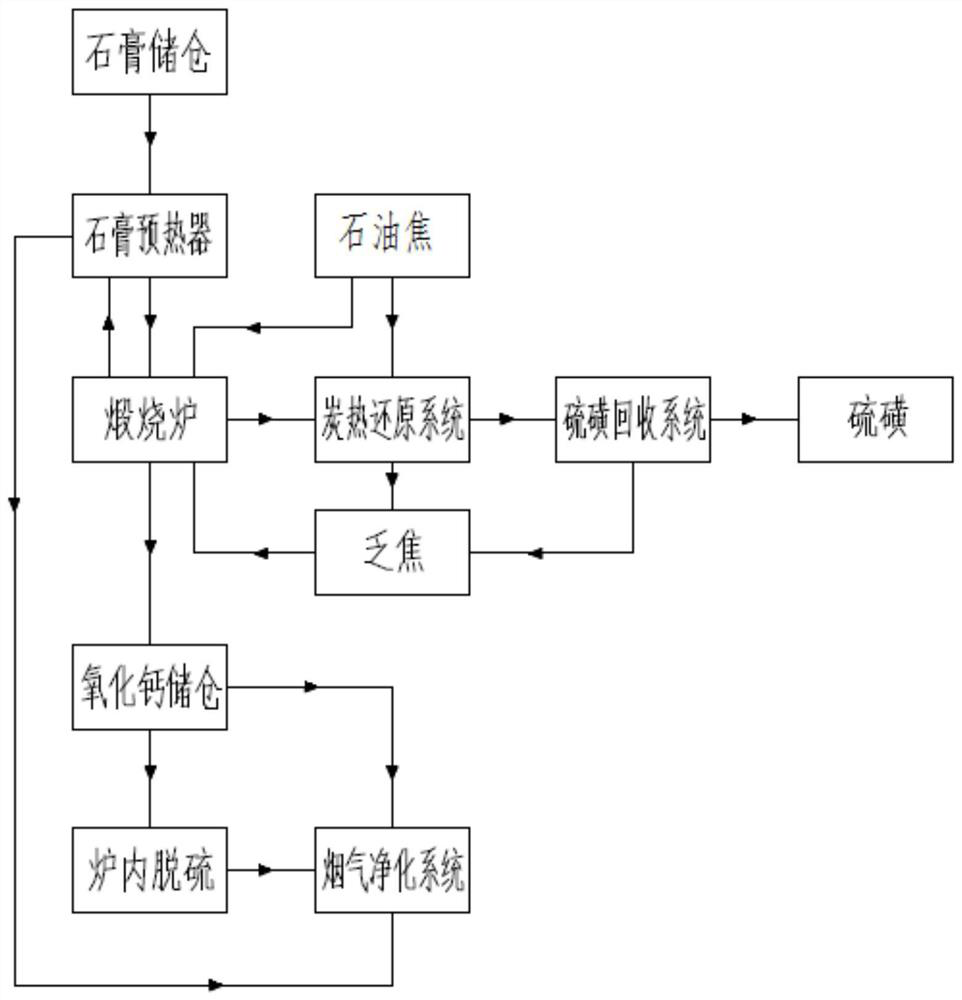

A system and method for synergistic gypsum calcination and carbon thermal reduction of petroleum coke

A petroleum coke and gypsum technology, applied in chemical instruments and methods, sulfur preparation/purification, inorganic chemistry, etc., can solve the problems of petroleum coke that is difficult to handle, and achieve the effects of saving consumption, saving resources, and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The particle size of the desulfurized gypsum is 60μm-3mm. Firstly, it is sent to the gypsum preheater through the feeder to accurately control the feeding amount, and is preheated to 500°C for preheating and drying. The preheated hemihydrate gypsum is added to the reduction calcination zone of the calciner, and petroleum coke and gypsum (particle size 60μm-3mm) are mixed according to C / CaSO 4 After the molar ratio of effective components is 20:1, it is mixed with high-temperature flue gas for indirect heat exchange, and then calcined. The calcining temperature is 800°C, and the calcining time is 40 minutes. The calcined solid product is CaS powder. The CaS powder is sent to the oxidation calcination zone of the calciner, and reacts with the incoming oxygen at 700°C to generate CaO and high-concentration SO 2 gas. high concentration SO 2 Gas (SO 2 content of 20%) into the carbon thermal reduction furnace, and petroleum coke for carbon thermal reduction, petroleum cok...

Embodiment 2

[0060] The particle size of phosphogypsum is 60μm-3mm. Firstly, the feeding amount is accurately controlled by the feeder and sent to the gypsum preheater, and it is preheated to 500°C for preheating and drying. The preheated phosphogypsum is added to the reduction calcination zone of the calciner, petroleum coke and gypsum (particle size 60μm-3mm) are mixed according to C / CaSO 4 The active components are mixed at a molar ratio of 10:1, and then indirect heat exchange with high-temperature flue gas for calcination. The calcination temperature is 650°C and the calcination time is 20 minutes. The calcined solid product is CaS powder. The CaS powder is sent to the oxidation calcination zone of the calciner, and reacts with the incoming oxygen at 750°C to generate CaO and high-concentration SO 2 gas. high concentration SO 2 Gas (SO 2 content of 10%) into the carbon thermal reduction furnace, and petroleum coke for carbon thermal reduction, petroleum coke and flue gas according...

Embodiment 3

[0063] The particle size of the natural gypsum is 60μm-3mm. Firstly, the feeding amount is accurately controlled by the feeder and sent to the gypsum preheater, and it is preheated to 700°C for preheating and drying. The preheated natural gypsum is added to the reduction calcination zone of the calciner, and petroleum coke and gypsum (particle size 60μm-3mm) are mixed according to C / CaSO 4 After the molar ratio of effective components is 5:1, it is mixed with high-temperature flue gas for indirect heat exchange, and then calcined. The calcining temperature is 850°C, and the calcining time is 20 minutes. The calcined solid product is CaS powder. The CaS powder is sent to the oxidation calcination zone of the calciner, and reacts with the incoming oxygen at 800°C to generate CaO and high-concentration SO 2 gas.

[0064] high concentration SO 2 Gas (SO 2 content of 30%) into the carbon thermal reduction furnace, and petroleum coke for carbon thermal reduction, petroleum coke ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com