Vertical water turbine upper frame lifting device

The utility model relates to a hydraulic turbine and vertical technology, which is applied to the field of the upper frame lifting device of a vertical hydraulic turbine, which can solve the problems of difficulty in lifting and long maintenance period, and achieve the effects of shortening the maintenance period, saving manpower and material resources, and eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be clearly and completely described below in conjunction with the accompanying drawings, so that those skilled in the art can fully implement the present invention without creative work.

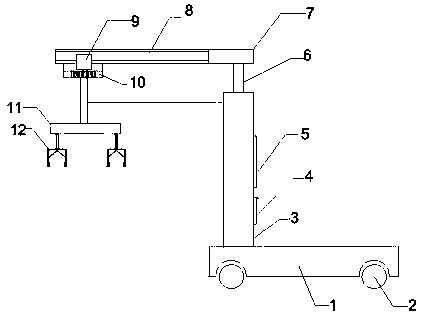

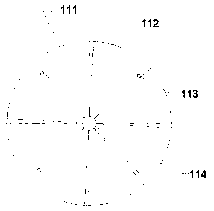

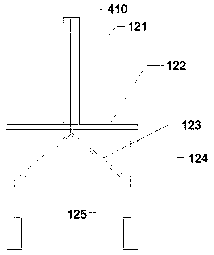

[0028] Such as Figure 1-6 As shown, in the embodiment of the present invention, a frame hoisting device on a vertical water turbine includes a base 1, a frame pillar 3, a coil mechanism 4, a transverse support 7, a lifting frame 11, and a clamp 12. The frame The pillar 3 is fixedly installed on one side of the base 1, the transverse support 7 is installed above the frame pillar 3, and is vertically connected with the frame pillar 3, and the free end of the transverse support 7 is connected with an electric A hoist 10, the lifting frame 11 is connected to the bottom of the electric hoist 10, a plurality of clamps 12 are uniformly installed on the bottom of the lifting frame 11, and the horizontal support 7 is provided with a slide rail 8 along the length dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com