Clutch and method for the production thereof

A technology for couplings and driven shafts, applied in the direction of couplings, elastic couplings, rigid shaft couplings, etc., can solve problems such as uneven layer thickness, reduced heat dissipation, and inability to fully interrupt electrical contact , to achieve the effect of simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

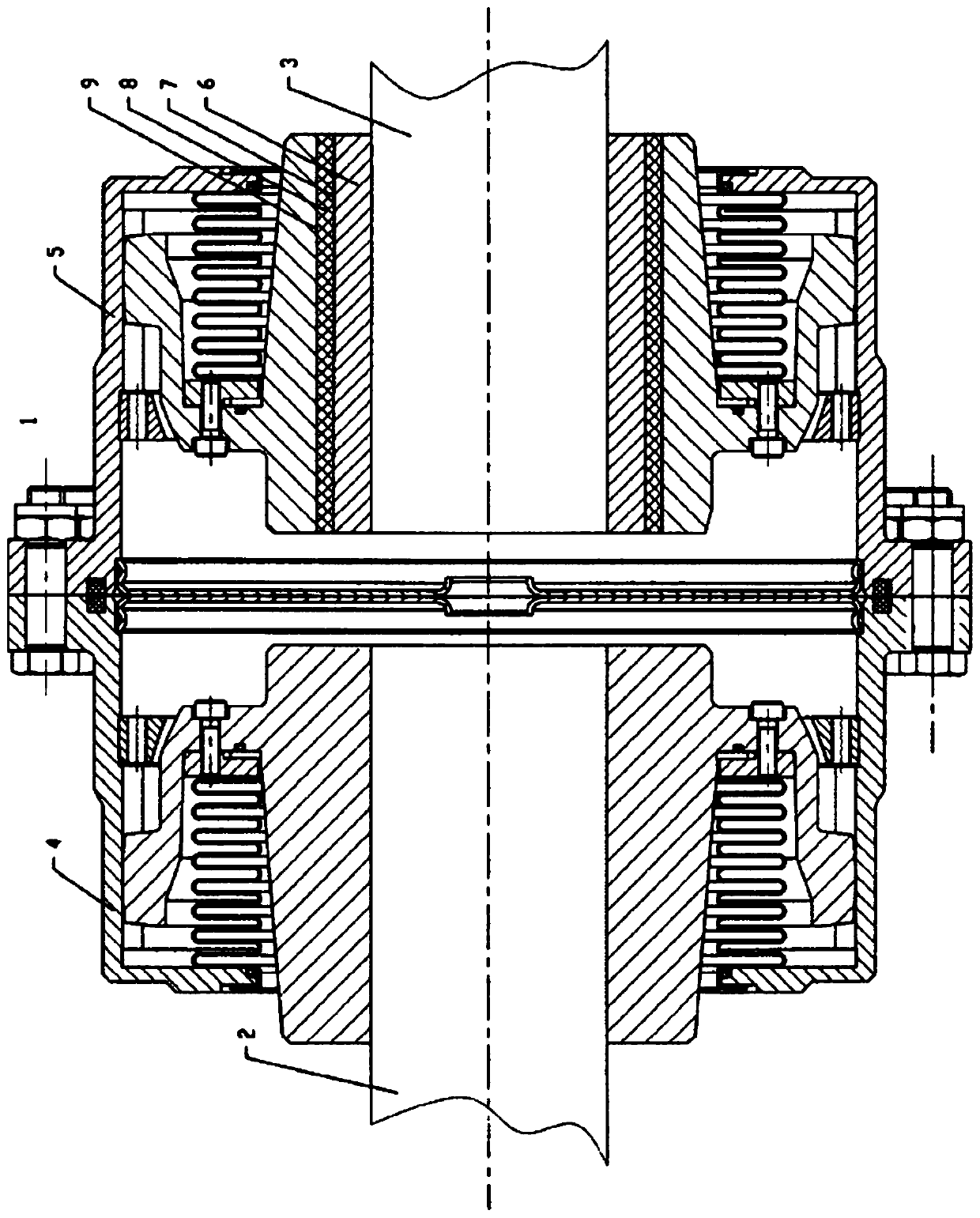

[0078] Gear coupling 1 is used to connect drive shaft 2 and driven shaft 3 . For example, the drive shaft 2 may be a motor shaft and the driven shaft 3 may be a propeller shaft of the vehicle. The gear coupling 1 essentially consists of two coupling halves 4 , 5 , one on the drive side 2 and the other on the output side 3 .

[0079] The coupling half 4 on the drive side 2 is unchanged from the prior art gear coupling. The coupling half 5 on the output side 3 has a structure according to the invention.

[0080] The inner diameter of the first inner hollow cylinder 6 made of steel corresponds to the outer diameter of the driven shaft 3 .

[0081] The first hollow cylinder 6 has a wall thickness of 14 mm and a length of 65 mm. With the aid of the knurling arranged parallel to the axis of rotation of the output shaft 3 , ribbed knurling 7 is introduced on the entire outer surface of the first hollow cylinder 6 . The ribs arranged parallel to each other had a height of 0.6 mm a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com