Machining robot for machining workpieces using laser beam and machining laser integrated into robot arm

A technology for processing workpieces and robotic arms, which is applied to laser parts, laser welding equipment, metal processing equipment, etc., can solve problems such as high weight and large equipment, and achieve the effect of saving cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

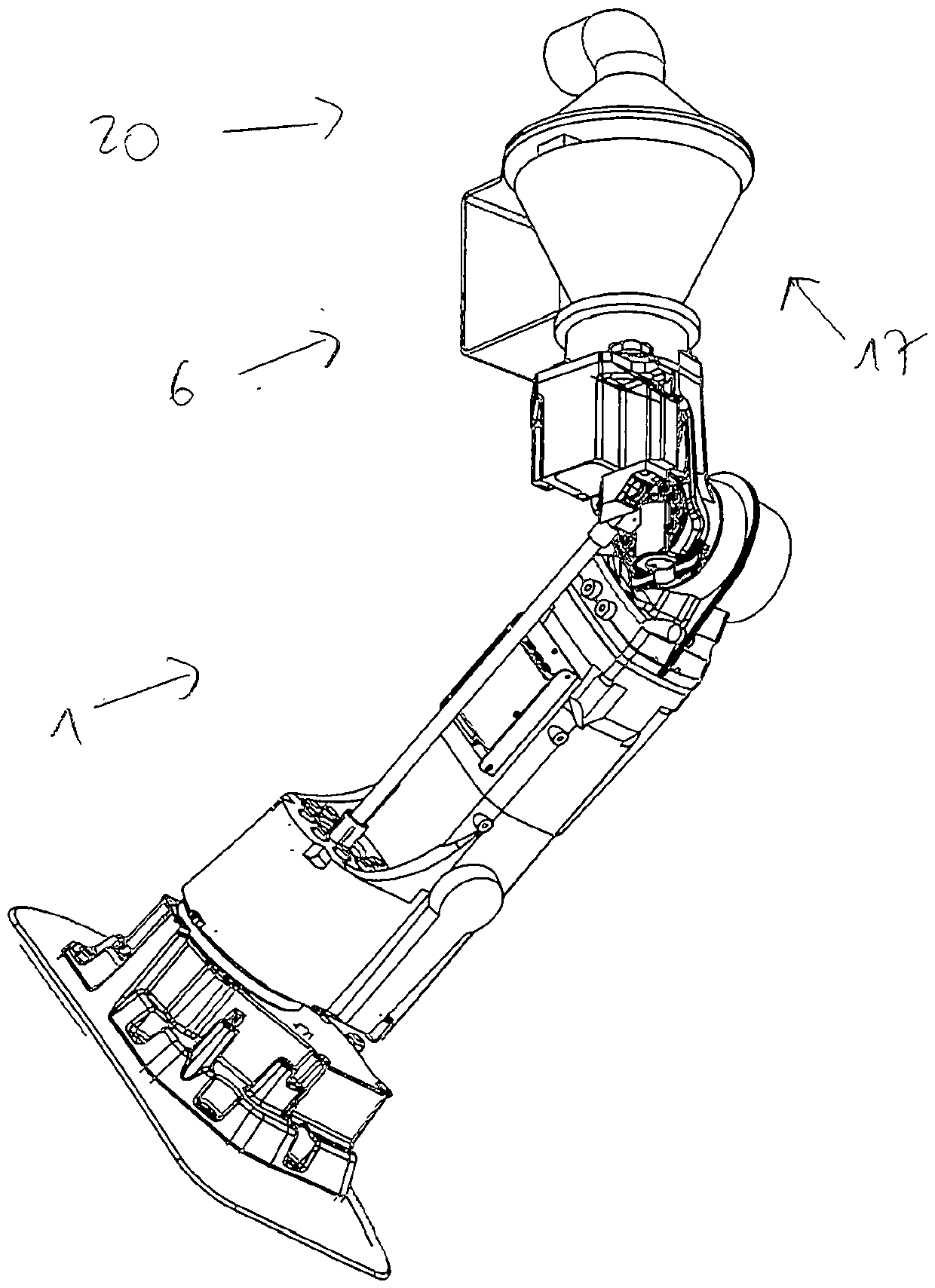

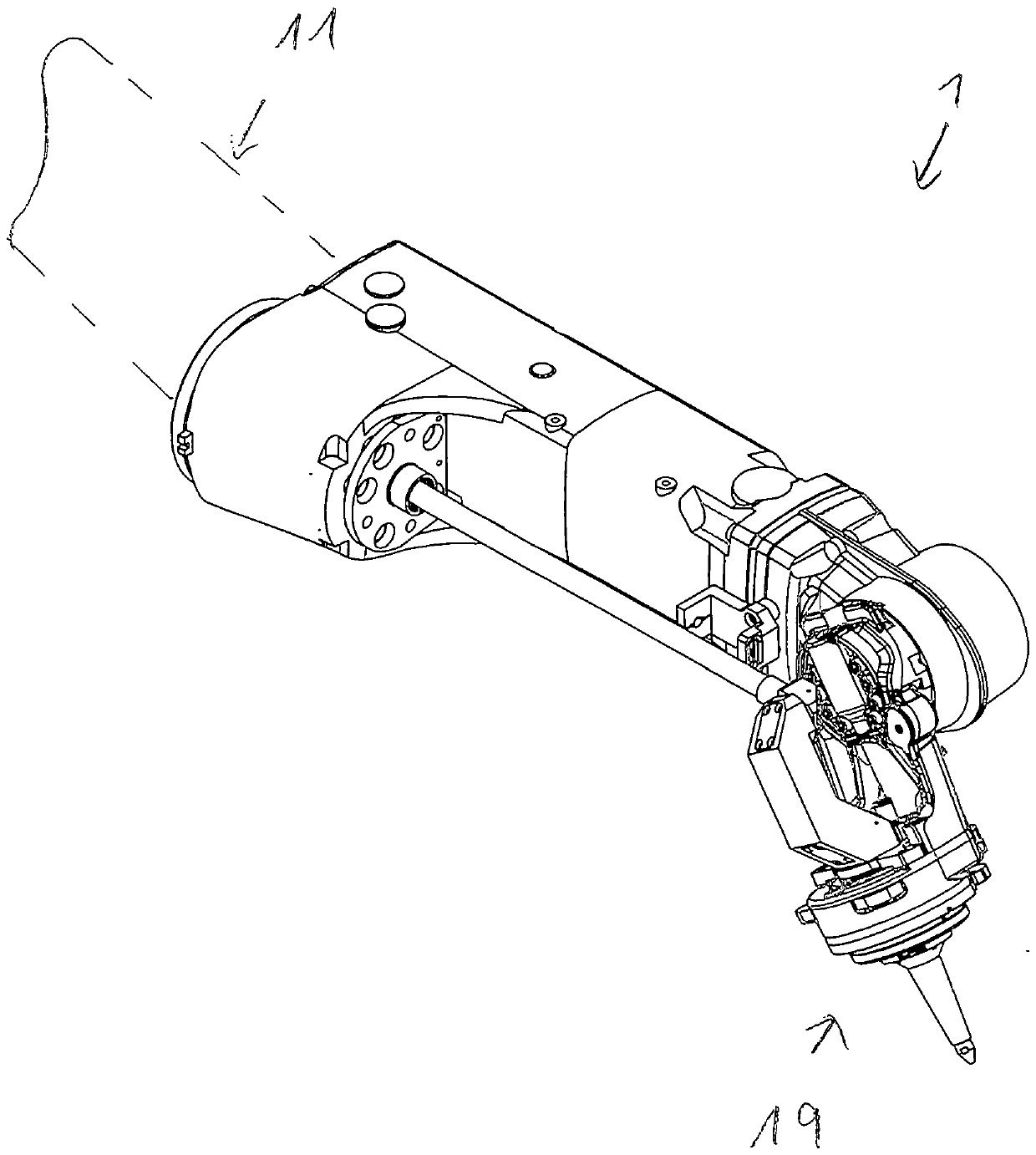

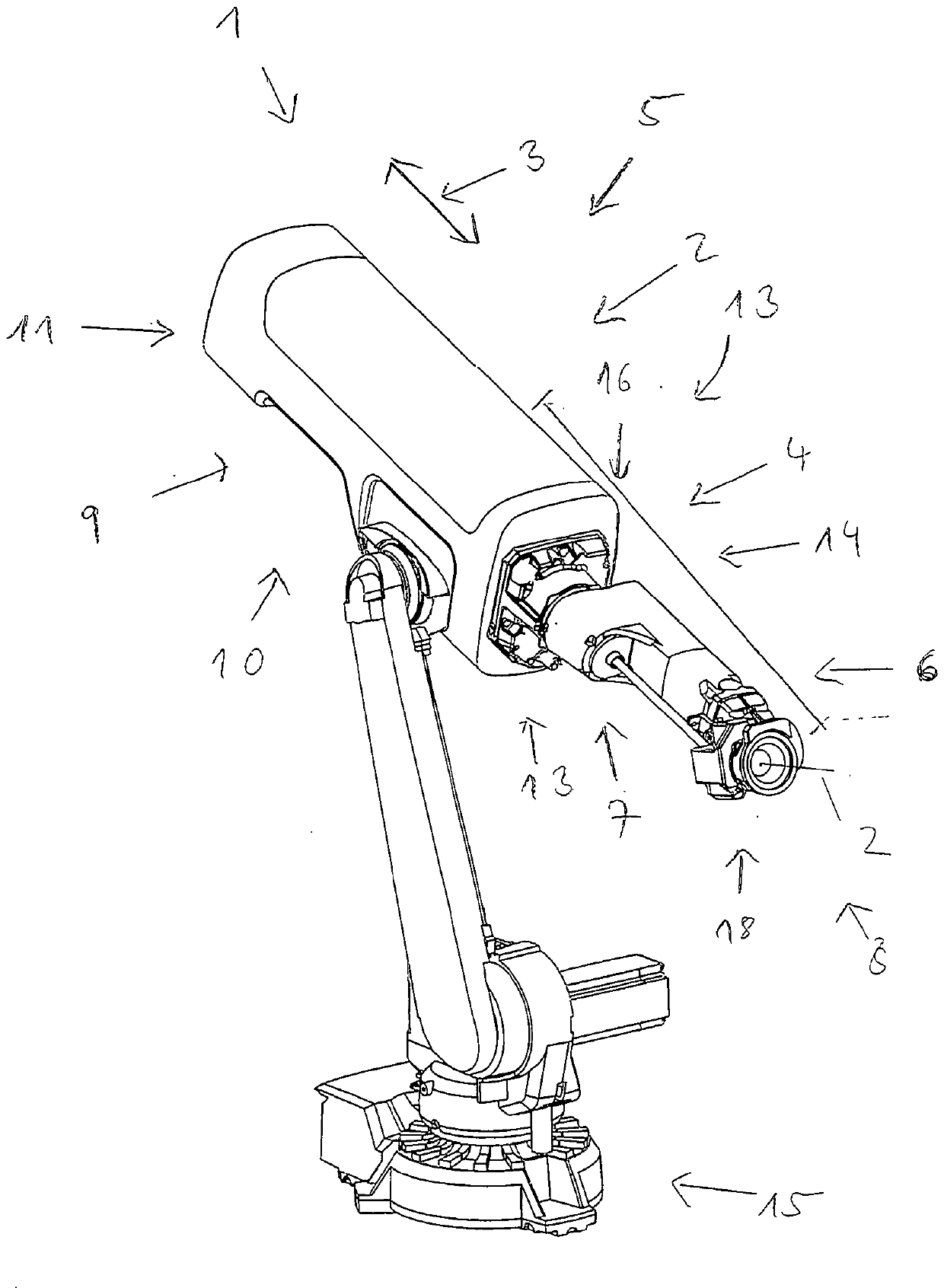

[0027] figure 1 A perspective view shows a processing robot 1 according to the invention, in particular a six-axis processing robot, for processing workpieces with a laser beam, wherein the laser beam 2 is essentially along the longitudinal axis of the processing robot 1 , in particular via a deflection device. 3 is guided via the articulated coupling means 14 to the inlet 4, to the central processing robot axis 5, until reaching the processing robot head 6, which has nozzle means 7 in particular around the output area 8 of the laser beam 2, wherein for The processing laser 9 generating the laser beam 2 is integrated in the processing robot arm 10 of the central processing robot axis 5 , which essentially comprises, in particular is formed of, a carbon housing 11 . A scanner 18 , in particular a high-power scanner, is installed in the processing robot head region 6 of the processing robot 9 .

[0028] The inlet 4 of the coupling device 3 is arranged on the side 7 of the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com