Pressure-free pulse electromagnetic valve and induction liquid receiving machine with same

A pulse solenoid valve and solenoid valve technology, applied in the field of solenoid valves, can solve problems such as the inability to realize liquid control, pulse solenoid valve technology to control the opening and closing of liquid in pipelines, and achieve reliable sealing, reduced sliding friction resistance, and sensitive and reliable work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

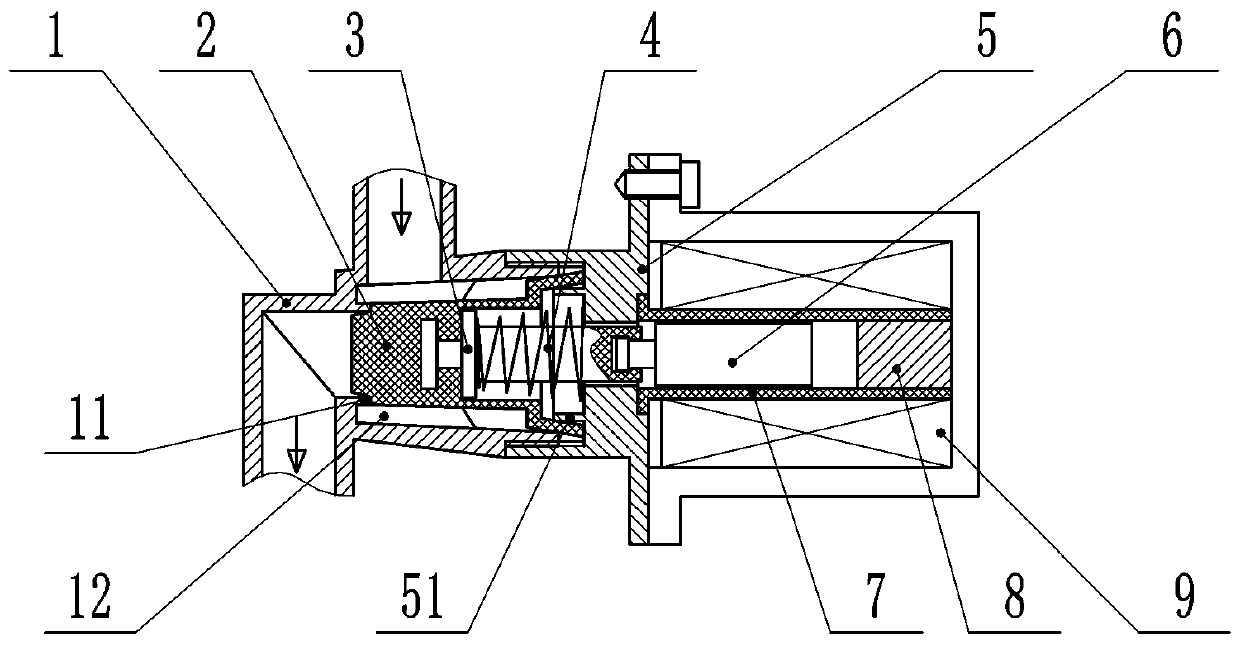

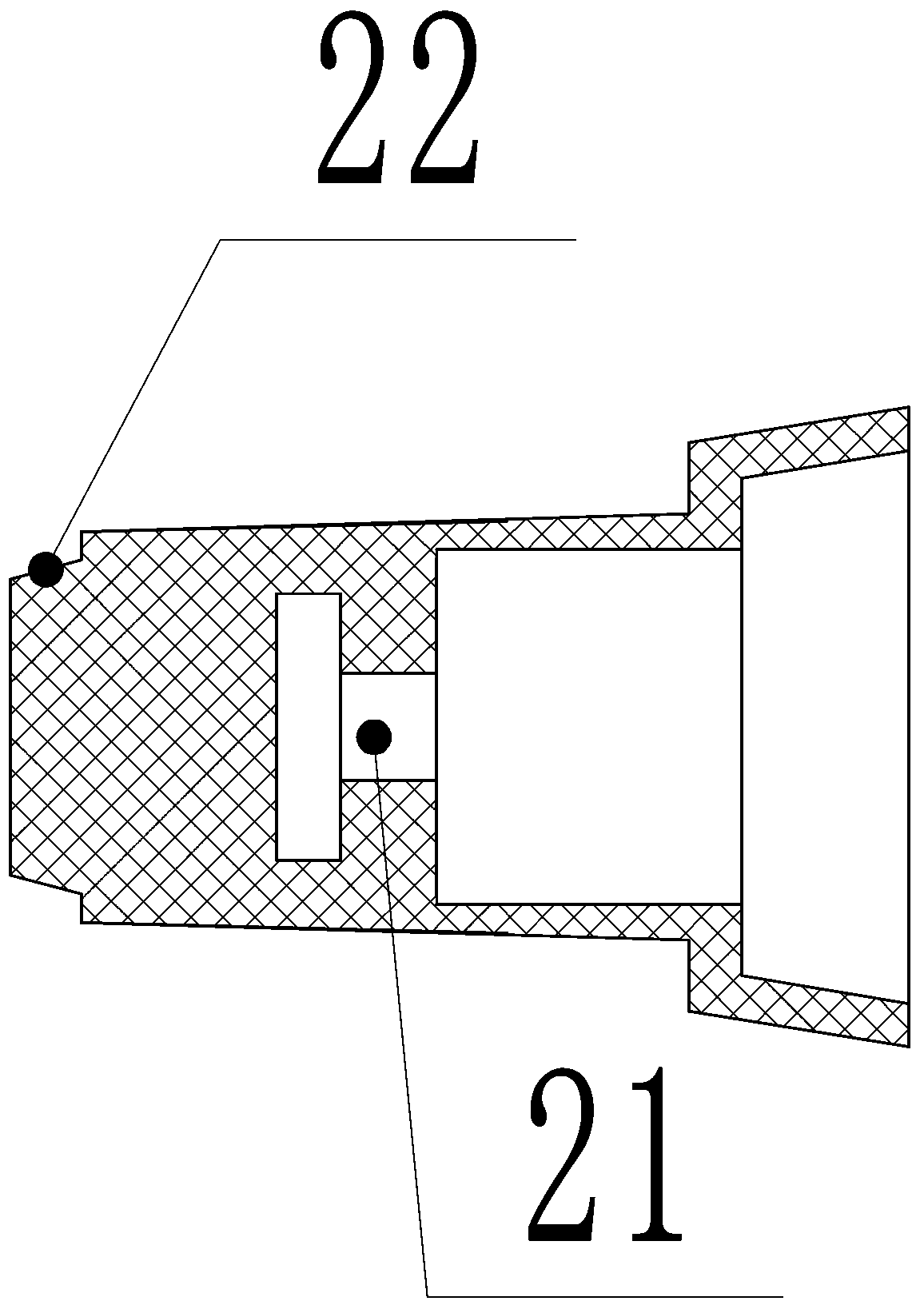

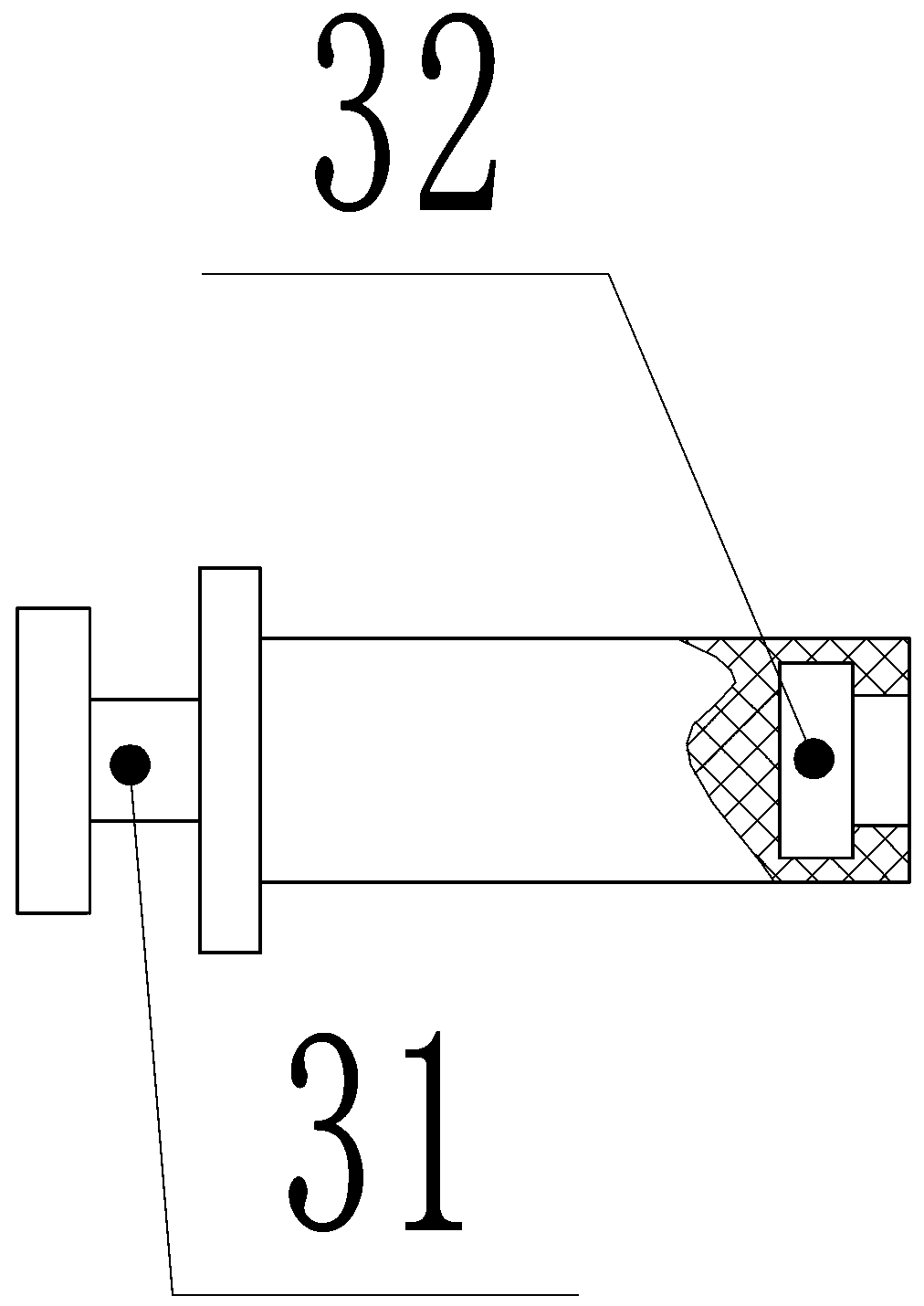

[0030]Embodiment 1, a pressureless pulse solenoid valve, said a pressureless pulse solenoid valve includes a valve body 1, a sealing plug 2, a pull rod 3, a spring 4, a valve cover 5, an electromagnet core 6, a permanent magnet 8, Coil winding 9, the valve body 1 is a corner or straight-through valve body, a cylindrical hole perpendicular to it is provided on the flow channel cross section of the valve body 1, and a raised sealing ring line 11 is provided at the bottom of the cylindrical hole, A supporting rib 12 is provided on the circumferential side wall at the bottom of the cylindrical hole. The sealing plug 2 is a cover with a thick bottom and a thin side wall. An inner annular groove 21 is provided on the inner side of the bottom of the sealing plug 2. The pull rod 3 It is a stepped pull rod, one end is large and the end is small, and an outer annular groove 31 is provided at the large end, and an inner annular groove 32 is provided at the small end. The valve cover 5 is ...

Embodiment 2

[0037] Embodiment 2, an induction liquid receiver with the non-pressure pulse solenoid valve, including the solenoid valve assembly 10, a liquid receiver housing 20, a pulse signal infrared induction probe 30, and the liquid receiver housing 20 It is a tubular casing, and a partition 201 is arranged in the middle of the tubular casing. The partition 201 divides the liquid receiver housing 20 into upper and lower chambers, and the upper chamber holds the liquid. The partition 201 and the liquid contact The casing 20 is an integral component, and the solenoid valve assembly 10 is arranged on the lower side of the partition 201, and the solenoid valve assembly 10 is fastened on the lower side of the partition 201 by nuts or screws. The liquid inlet of 10 is connected with the liquid in the upper cavity, and a cover plate 202 is arranged on the lower side of the solenoid valve assembly 10, and the cover plate 202 is fastened on the solenoid valve assembly 10 by nuts or screws. The...

Embodiment 3

[0043] Embodiment 3, the liquid-contacting machine housing 20 is integrated with the valve body 1 of the solenoid valve, the partition plate 201 and the lower cover plate 202, and the gasket 205 and the connecting gasket 205 are omitted at the same time. nuts or screws.

[0044] When in use, the user can approach or leave the liquid-contacting spoon or cup to trigger the pulse signal infrared sensor probe, and the pulse signal infrared sensor probe will give the solenoid valve assembly a pulse signal to control its opening and closing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com