Electromagnetic direct-drive reversing multi-way valve

A multi-way valve and reversing valve technology, applied in the field of multi-way valves, can solve the problems of complex structure, high manufacturing cost and slow response speed of electromechanical control reversing valve, so as to achieve flexible and fast spool reversing action, Simplify structural parts and reduce the impact of reversing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

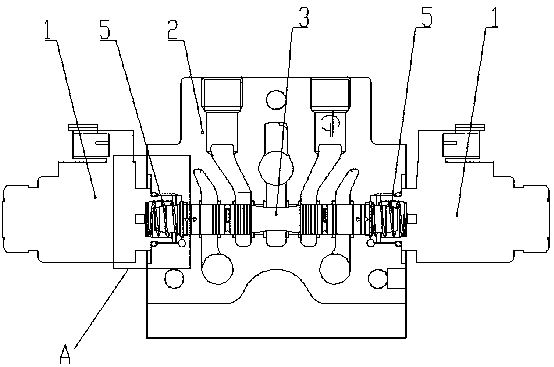

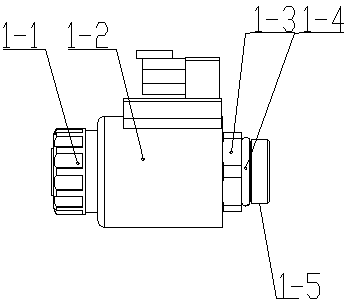

[0018] combine figure 1 and image 3 As shown, an electromagnetic direct-drive reversing multi-way valve has a valve core installation hole on the valve body 2, and a reversing valve core 3 is slidably installed in the valve core installation hole; The oil port connected by the hole. The two ends of the spool mounting hole of the valve body 2 are fixedly connected with an electromagnetic drive device 1. The electromagnetic drive device 1 is internally equipped with an electromagnetic coil 1-2 that cooperates with the drive mechanism 1-3. The outer end of the electromagnetic drive device 1 is provided with a locking plastic nut. 1-1.

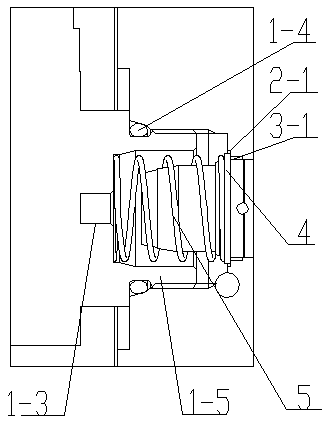

[0019] combine figure 2 As shown, the two ends of the spool mounting hole of the valve body 2 are provided with an inner stop 2-1, and the end of the reversing spool 3 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com