Inflatable seismic mitigation and absorption tunnel lining structure and construction method

A technology for shock isolation and lining, applied in tunnel lining, tunnel, shaft lining and other directions, can solve the problems of easy corrosion and failure of foam materials, reducing the rigidity of tunnel structure, unable to meet static requirements, etc., to achieve convenient construction and improve seismic resistance. High-level, practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The features of the present invention will be further described below in conjunction with the accompanying drawings and specific examples, which are only used to explain the present invention, and are not limited to this example. After reading the present invention, all equivalent replacements and modifications made within the principle of the present invention belong to the protection scope of the present invention.

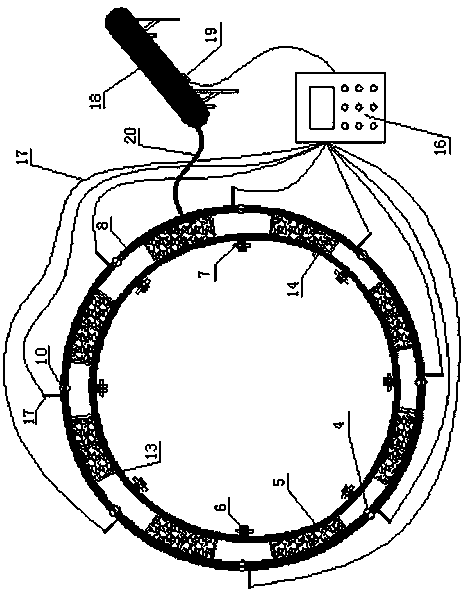

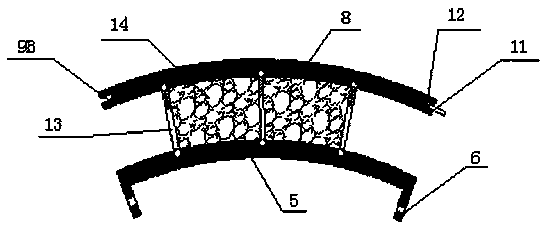

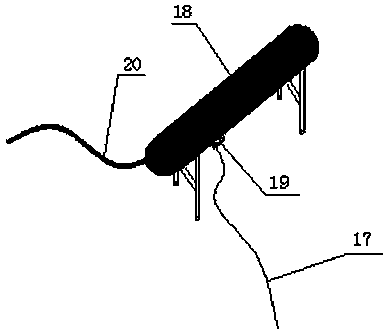

[0019] like Figure 1~Figure 7As shown, the inflatable shock-absorbing and isolation tunnel lining structure of the present invention includes a combined FRP lining segment 1, a segment connector 10, a large deformation waterstop 4, a displacement monitoring device 2 and an intelligent hydraulic inflation device 3; it is characterized in that : The combined fiberglass lining segment 1 is composed of an inner layer of curved glass steel plate 5, an outer layer of curved glass steel plate 8, a damping rod 13 and an inflatable air bag 14; four sides of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com