A self-healing composite material with polarization patterning ability and its preparation method

A polarization pattern and composite material technology, applied in the direction of additive processing, instruments, optical components, etc., can solve the problems of limited application fields, and achieve the effect of simple process, realization of polarization patterning, and mild and controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Preparation method

[0047] S1: Dissolve 8.5 parts of methacrylic acid and 21.5 parts of 3-(2-methacryloyloxyethyldimethylamino)propanesulfonate in 70 parts of water and mix evenly, add 0.3 parts of 10% initiator Ammonium sulfate was polymerized at 70°C for 10 hours under the condition of blowing nitrogen gas to obtain a copolymer.

[0048] S2: Add 0.3 parts of gold nanorods with an aspect ratio of 2.0 to the copolymer prepared in step S1, heat to 80° C. and mix uniformly to obtain a nano metal polymer.

[0049] S3: Dissolve 0.05 parts of ferric chloride and 0.25 parts of citric acid in 6 parts of water, adjust the pH to 3, add to the nano metal rod polymer prepared in step S2, heat to 80°C and mix well to obtain a polarized patterned capable self-healing composites.

[0050] 2. Result analysis

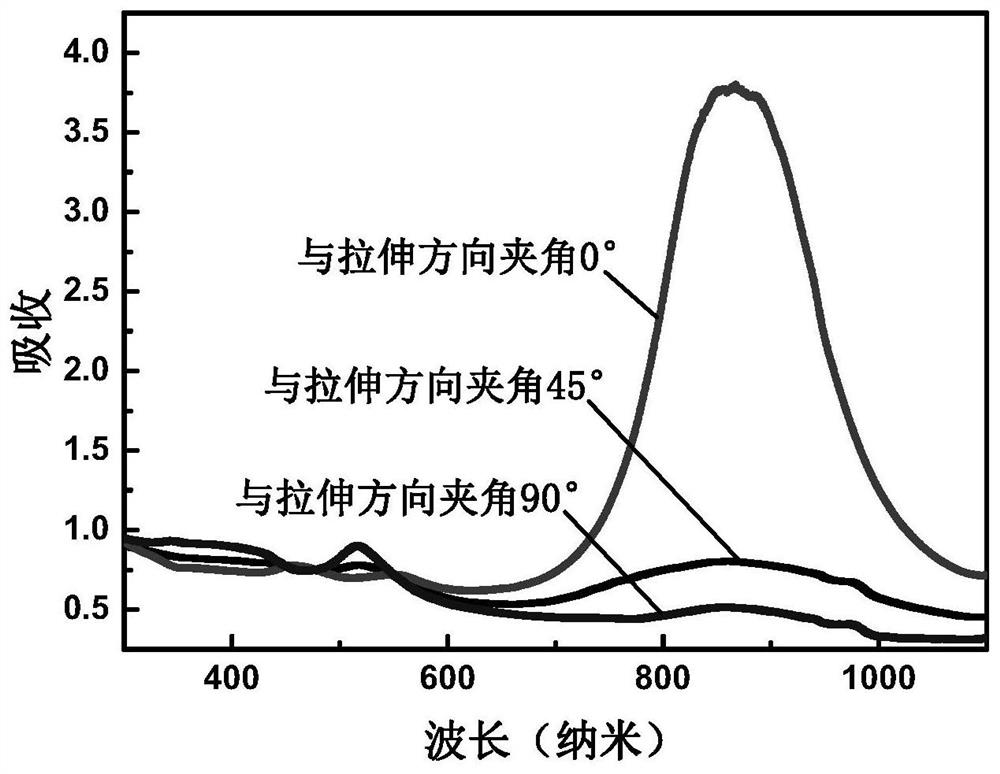

[0051] (1) Polarized optical properties

[0052] Such as figure 1 As shown, after the nano metal rod polymer of the present invention is stretched, in different polarized...

Embodiment 2

[0056] 1. Preparation method

[0057] S1: Dissolve 8.5 parts of methyl methacrylate and 21.5 parts of 3-(2-methacryloyloxyethyldimethylamino)propanesulfonate in 70 parts of water and mix evenly, add 0.3 parts of 10% initiator Potassium persulfate was used as an agent, and under the condition of blowing nitrogen, the polymerization reaction was carried out at 70°C for 10 hours to obtain a copolymer.

[0058] S2: Add 0.3 parts of gold nanorods with an aspect ratio of 3.0 to the polymer prepared in step S1, heat to 80° C. and mix evenly to obtain a nano-metal polymer.

[0059] S3: Dissolve 0.05 parts of ferric chloride and 0.25 parts of citric acid in 6 parts of water, adjust the pH to 3, add them to the nano-gold rod polymer prepared in step S2, heat to 80°C and mix evenly to obtain a polarized patterning ability Self-healing composites.

[0060] 2. Result analysis

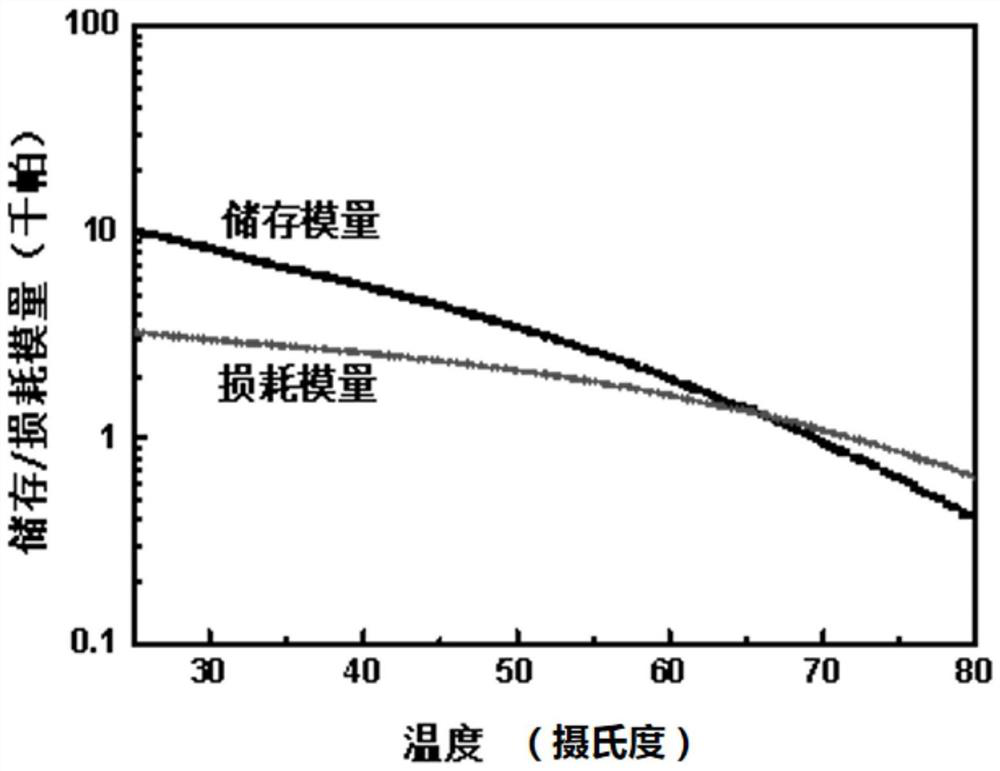

[0061] (1) Self-repair

[0062] Such as image 3 As shown, the rheological test of the nano metal rod polyme...

Embodiment 3

[0066] 1. Preparation method

[0067] S1: Dissolve 8.5 parts of methacrylic acid and 21.5 parts of 3-(2-methacryloyloxyethyldimethylamino)propanesulfonate in 70 parts of water and mix evenly, add 0.3 parts of 10% initiator Ammonium sulfate was polymerized at 70°C for 10 hours under the condition of blowing nitrogen gas to obtain a copolymer.

[0068] S2: Add 0.3 parts of gold nanorods with an aspect ratio of 4.7 to the polymer prepared in step S1, heat to 80° C. and mix evenly to obtain a nano metal polymer.

[0069] S3: Dissolve 0.1 part of ferric chloride and 0.5 part of citric acid in 6 parts of water, adjust the pH to 3, add to the nano-gold polymer prepared in step S2, heat to 80 ° C and mix evenly to obtain a polarized patterning ability Self-healing composites.

[0070] 2. Result analysis

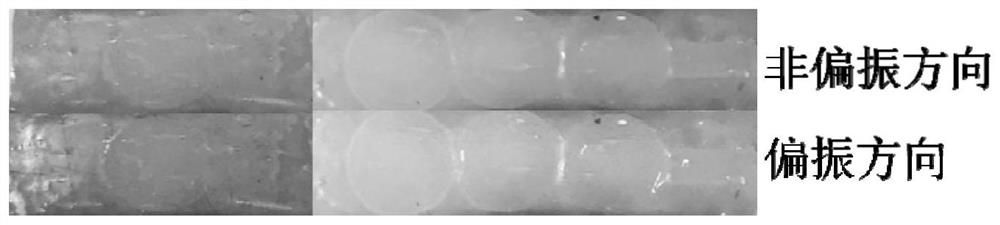

[0071] (1) Pattern hidden

[0072] The nano-gold rod prepared by the method has an absorption wavelength of about 880nm. When the concentration of nano-gold rods is low enough, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com