Self-repairing composite material having polarization patterning capability and preparation method thereof

A polarization pattern and composite material technology, applied in additive processing, instruments, optics, etc., can solve problems such as limited application fields, and achieve the effects of simple process, self-repair, and polarization patterning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Preparation method

[0047] S1: Dissolve 8.5 parts of methacrylic acid and 21.5 parts of 3-(2-methacryloyloxyethyldimethylamino)propanesulfonate in 70 parts of water and mix evenly, add 0.3 parts of 10% initiator Ammonium sulfate was polymerized at 70°C for 10 hours under the condition of blowing nitrogen gas to obtain a copolymer.

[0048] S2: Add 0.3 parts of gold nanorods with an aspect ratio of 2.0 to the copolymer prepared in step S1, heat to 80° C. and mix uniformly to obtain a nano metal polymer.

[0049] S3: Dissolve 0.05 parts of ferric chloride and 0.25 parts of citric acid in 6 parts of water, adjust the pH to 3, add to the nano metal rod polymer prepared in step S2, heat to 80°C and mix well to obtain a polarized patterned capable self-healing composites.

[0050] 2. Result analysis

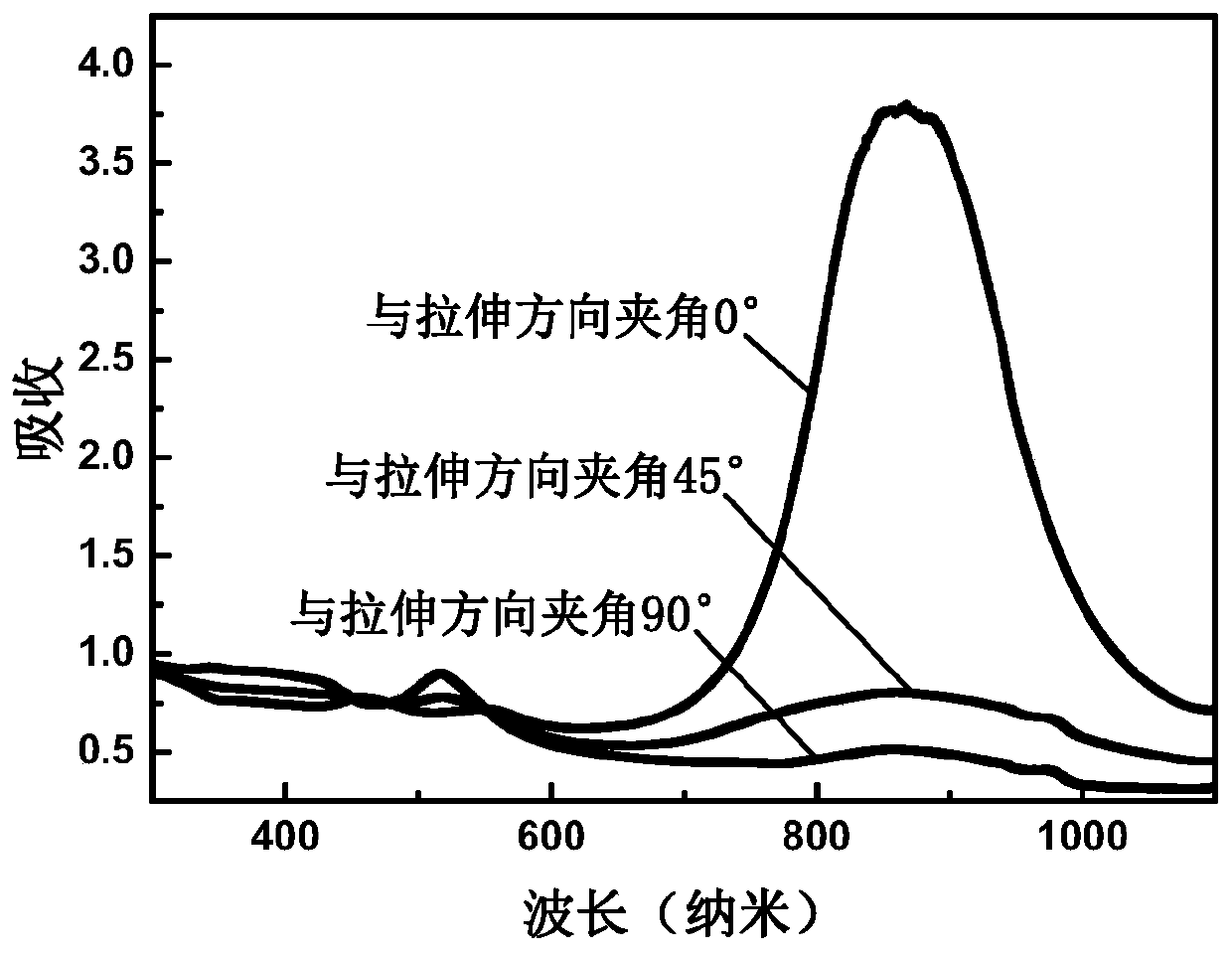

[0051] (1) Polarized optical properties

[0052] Such as figure 1 As shown, after the nano metal rod polymer of the present invention is stretched, in different polarized...

Embodiment 2

[0056] 1. Preparation method

[0057] S1: Dissolve 8.5 parts of methyl methacrylate and 21.5 parts of 3-(2-methacryloyloxyethyldimethylamino)propanesulfonate in 70 parts of water and mix evenly, add 0.3 parts of 10% initiator Potassium persulfate was used as an agent, and under the condition of blowing nitrogen, the polymerization reaction was carried out at 70°C for 10 hours to obtain a copolymer.

[0058] S2: Add 0.3 parts of gold nanorods with an aspect ratio of 3.0 to the polymer prepared in step S1, heat to 80° C. and mix evenly to obtain a nano-metal polymer.

[0059] S3: Dissolve 0.05 parts of ferric chloride and 0.25 parts of citric acid in 6 parts of water, adjust the pH to 3, add them to the nano-gold rod polymer prepared in step S2, heat to 80°C and mix evenly to obtain a polarized patterning ability Self-healing composites.

[0060] 2. Result analysis

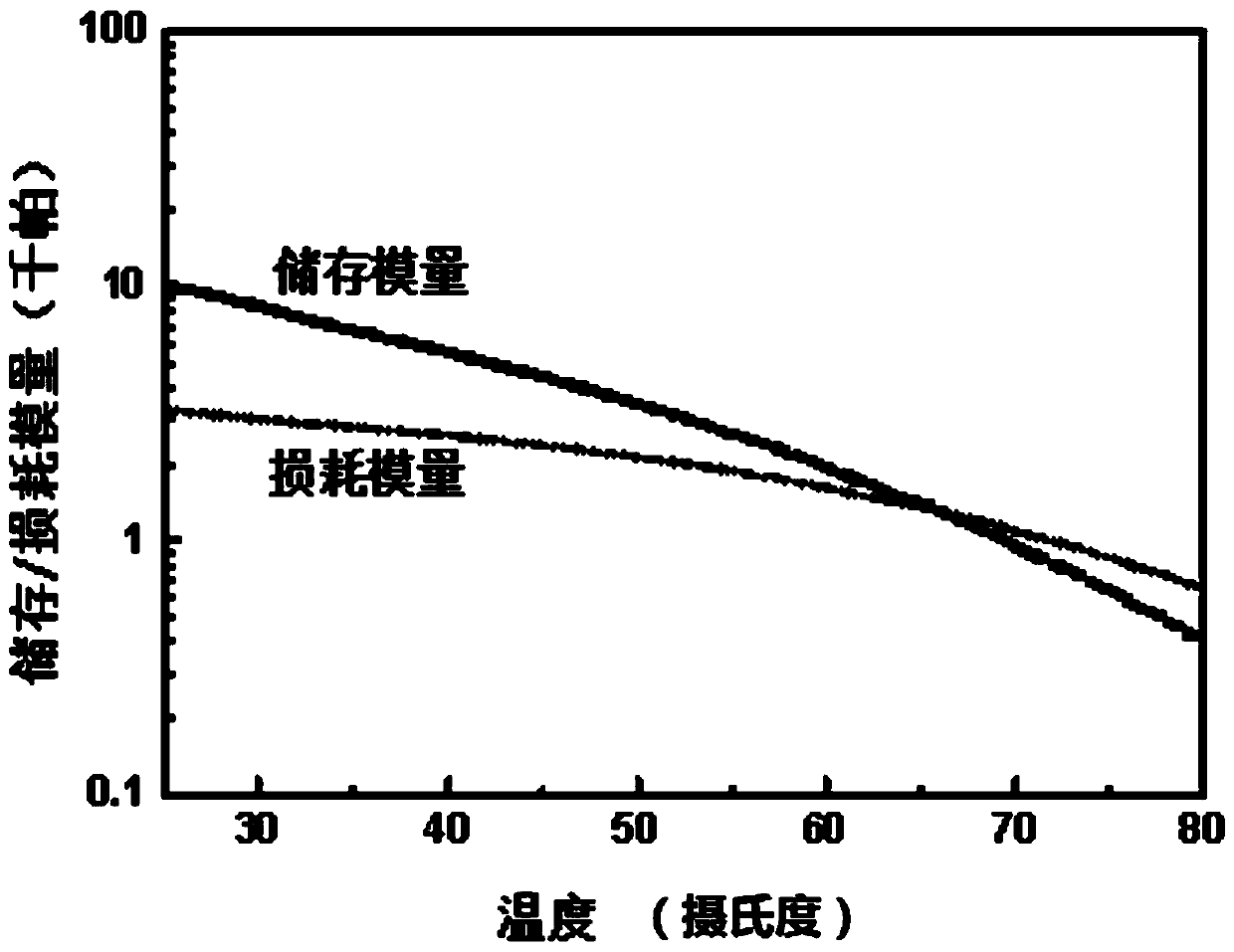

[0061] (1) Self-repair

[0062] Such as image 3 As shown, the rheological test of the nano metal rod polyme...

Embodiment 3

[0066] 1. Preparation method

[0067] S1: Dissolve 8.5 parts of methacrylic acid and 21.5 parts of 3-(2-methacryloyloxyethyldimethylamino)propanesulfonate in 70 parts of water and mix evenly, add 0.3 parts of 10% initiator Ammonium sulfate was polymerized at 70°C for 10 hours under the condition of blowing nitrogen gas to obtain a copolymer.

[0068] S2: Add 0.3 parts of gold nanorods with an aspect ratio of 4.7 to the polymer prepared in step S1, heat to 80° C. and mix evenly to obtain a nano metal polymer.

[0069] S3: Dissolve 0.1 part of ferric chloride and 0.5 part of citric acid in 6 parts of water, adjust the pH to 3, add to the nano-gold polymer prepared in step S2, heat to 80 ° C and mix evenly to obtain a polarized patterning ability Self-healing composites.

[0070] 2. Result analysis

[0071] (1) Pattern hidden

[0072] The nano-gold rod prepared by the method has an absorption wavelength of about 880nm. When the concentration of nano-gold rods is low enough, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com