Fluidity detection device for concrete powder

A detection device and fluidity technology, which is applied to clay preparation devices, sales raw material supply devices, liquid batching supply devices, etc., can solve problems affecting powder detection efficiency, improve batching and detection efficiency, and set up a simple structure. concise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the drawings.

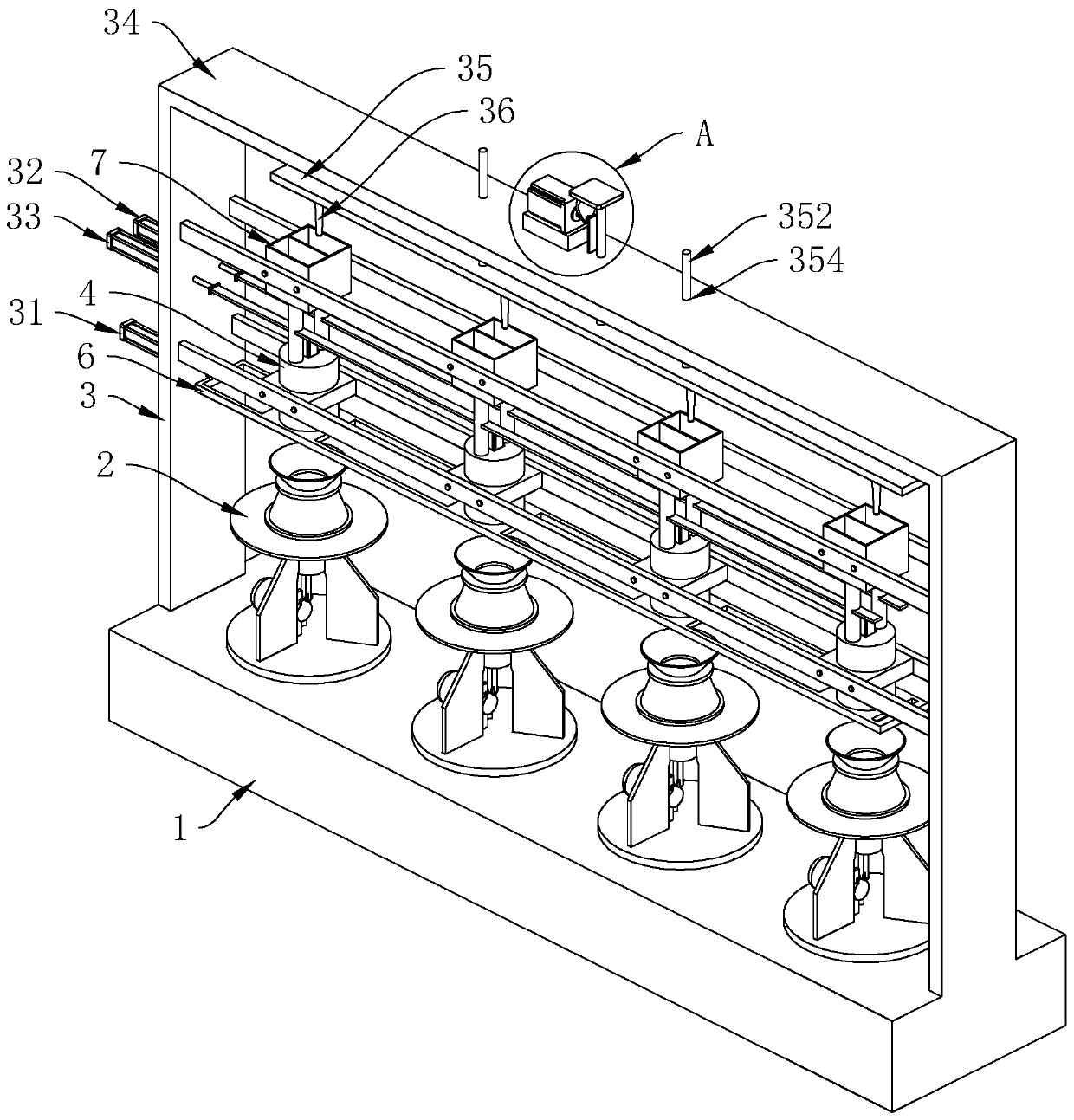

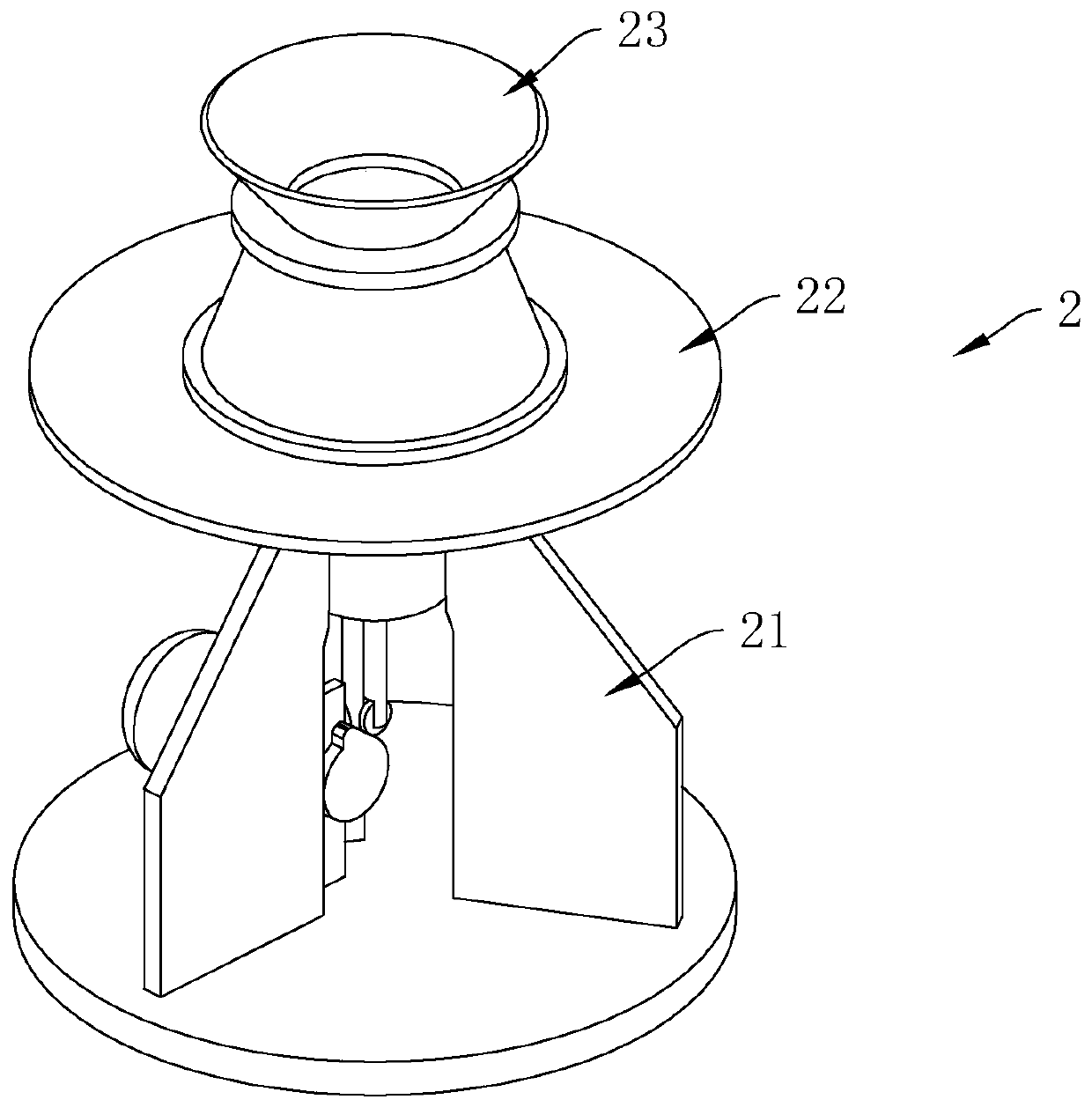

[0038] Such as figure 1 , figure 2 As shown, a concrete powder fluidity detection device includes a long-strip base 1 with a plurality of measuring instruments 2 arranged at intervals. The measuring instrument 2 includes a body 21 on which a workbench 22 is horizontally arranged, and a shaping cylinder 23 is arranged on the workbench 22.

[0039] When using the above detection device, after mixing a variety of weighed powders and water evenly, the slurry is put into a plurality of sizing cylinders 23, and then the sizing cylinder 23 is removed to allow the slurry to flow on the surface of the workbench 22. After a period of time, record the spread diameter and area of the slurry to complete the powder fluidity test.

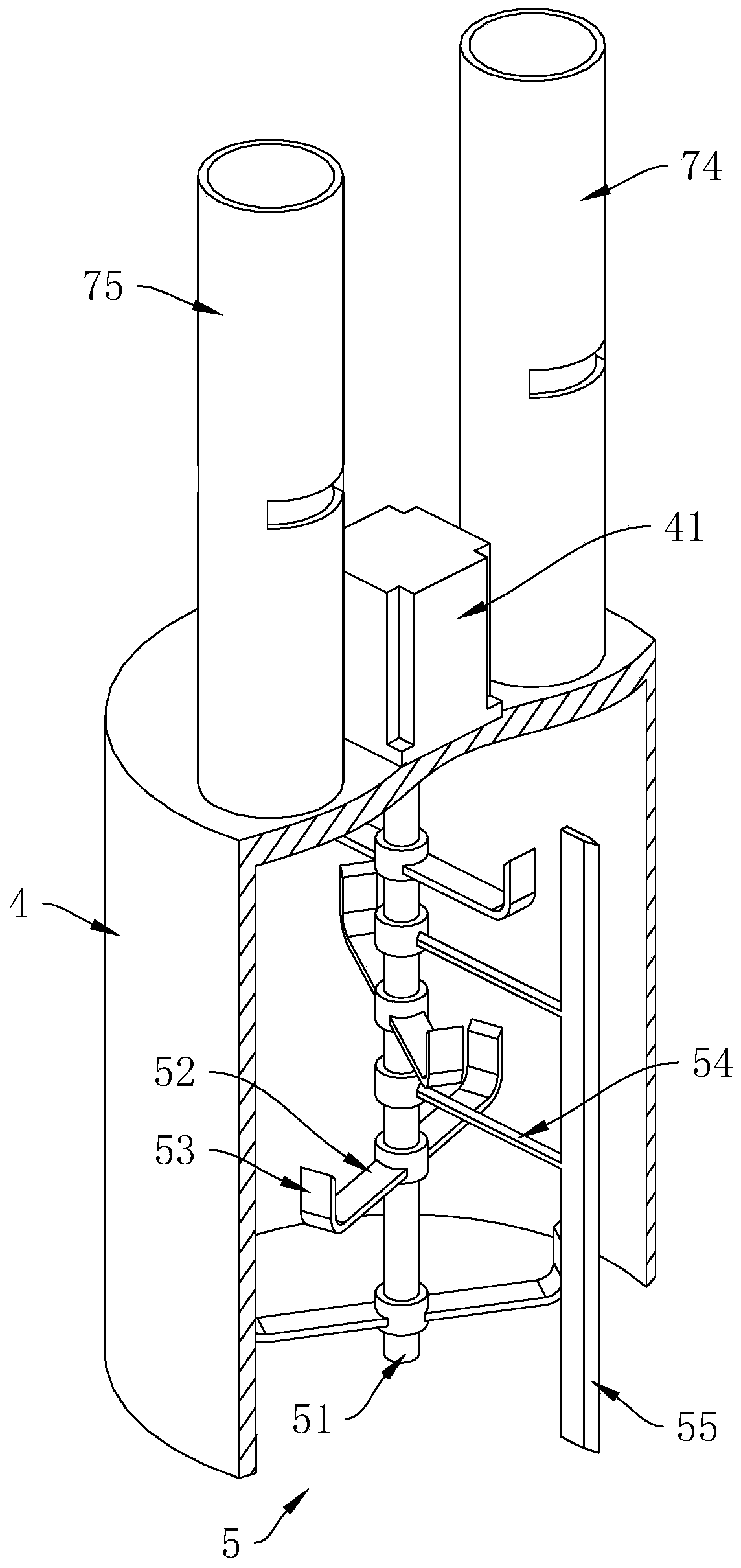

[0040] Such as figure 1 , image 3 As shown, the base 1 is provided with a frame 3, and a plurality of mixing boxes 4 are arranged on the frame 3, and the plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com