Carbon environmental protecting type burden charging carriage

An environment-friendly, batching vehicle technology, applied in the direction of mixer accessories, sales of raw material supply devices, dissolution, etc., can solve the problems of large heat loss of raw materials, poor batching effect, affecting the workshop environment, etc., to reduce the probability of batching errors and batching time , save the time of dry mixing, and improve the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

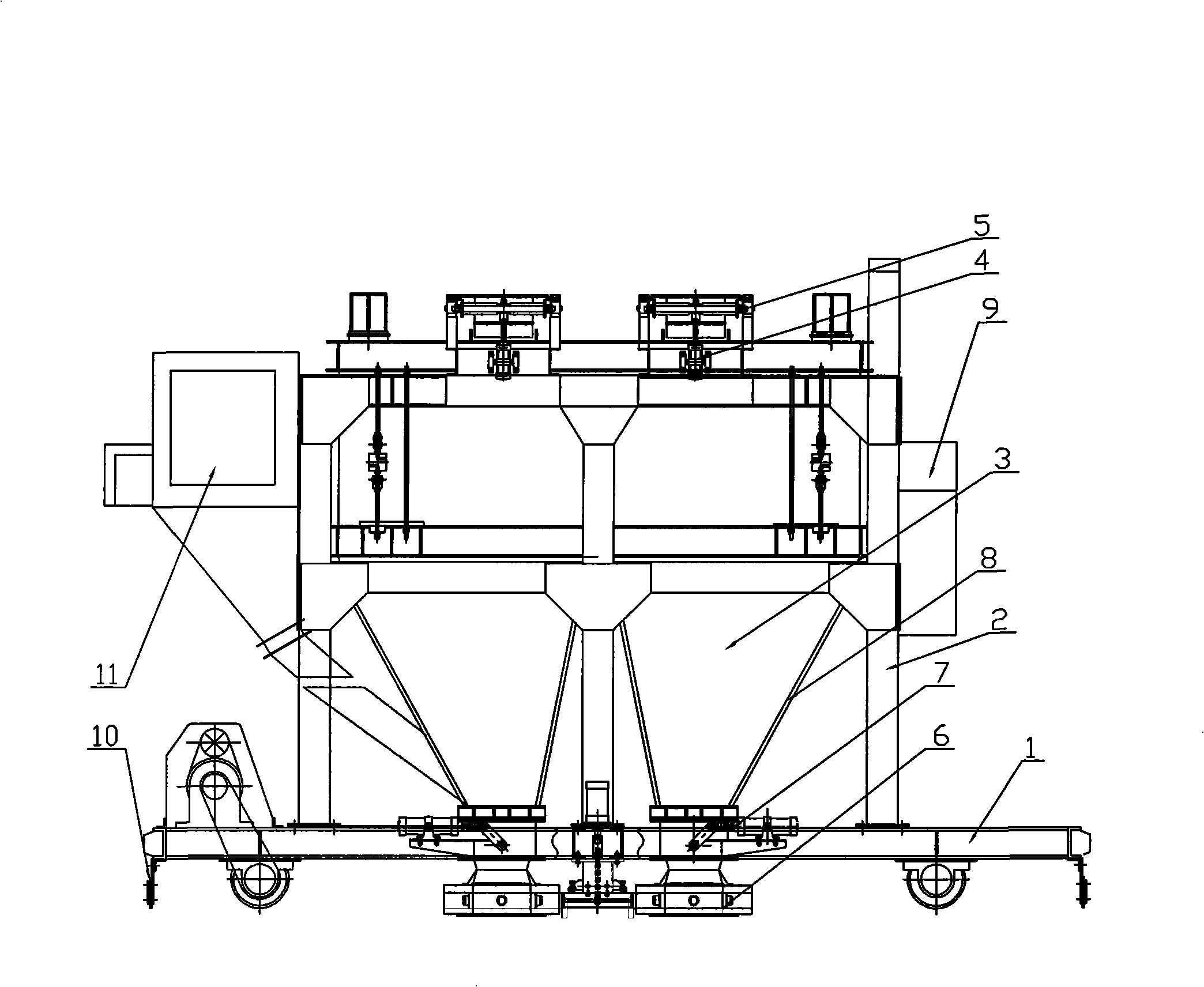

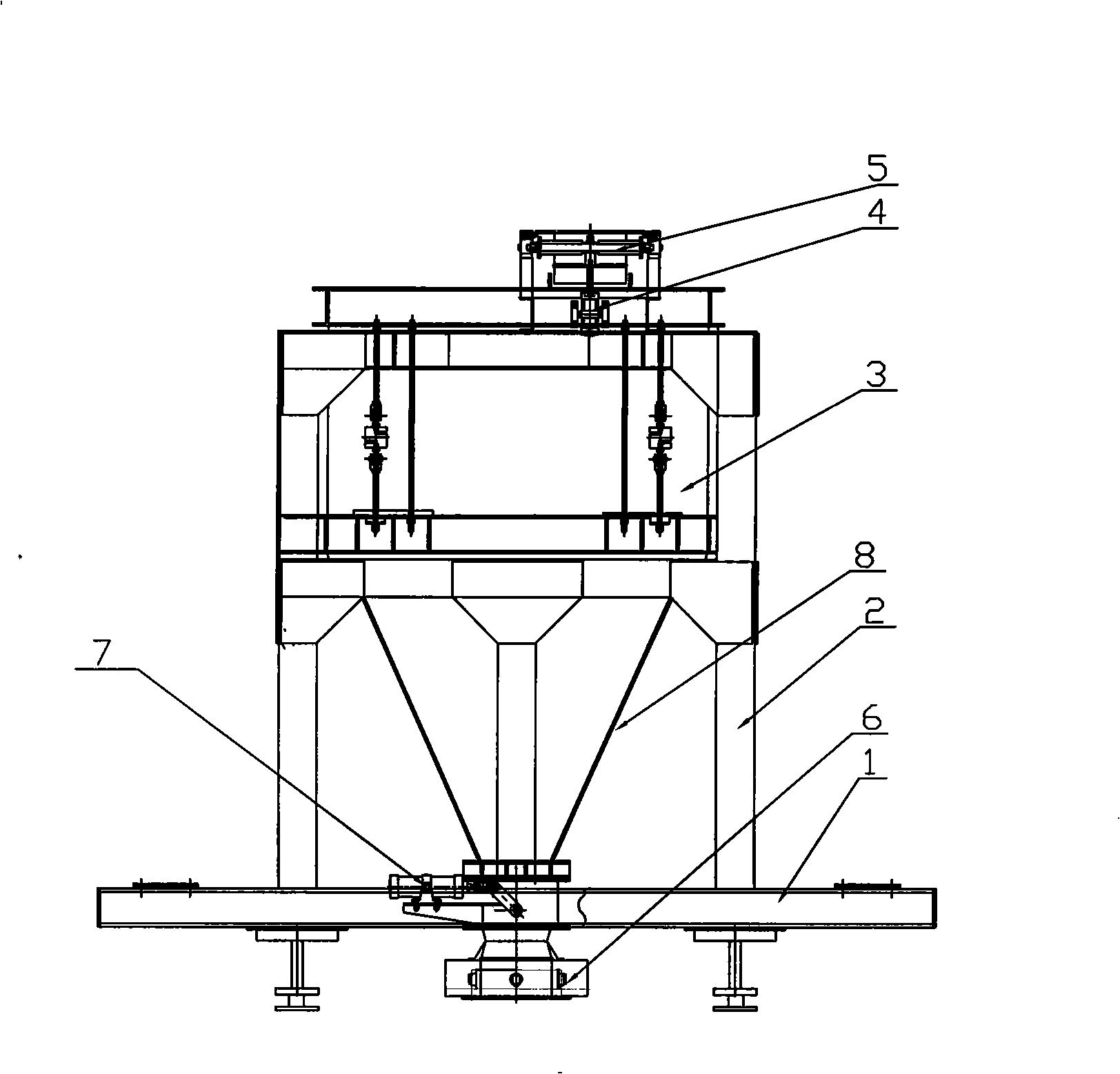

[0022] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

[0023] The carbon environment-friendly batching vehicle of the present invention comprises a flat trolley 1, a fixed support 2, a collection bin 3, a feed inlet and a discharge outlet, and an insulation layer 8 is arranged on the outer wall of the collection bin 3, and the insulation layer 8 dissipates heat to make the surrounding The ambient temperature is less than 40 degrees; the feed pusher 4 and the discharge pusher 7 are provided at the feed port and the discharge port, and positioning sensors 10 are provided at both ends of the flat trolley 1; A dust remover 11 and a control box 9 are arranged on the outside, and the dust collecting port of the dust remover 11 communicates with the feed port and the discharge port.

[0024] The above-mentioned feed pusher 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com