Horizontal linear motor structure and implementation method thereof

A horizontal linear motor technology, which is applied in the field of horizontal linear motor structure and its realization, can solve the problems of cost difference and fewer horizontal motors, and achieve the effects of consistent motion space, reduced stop time, and increased magnetic field utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

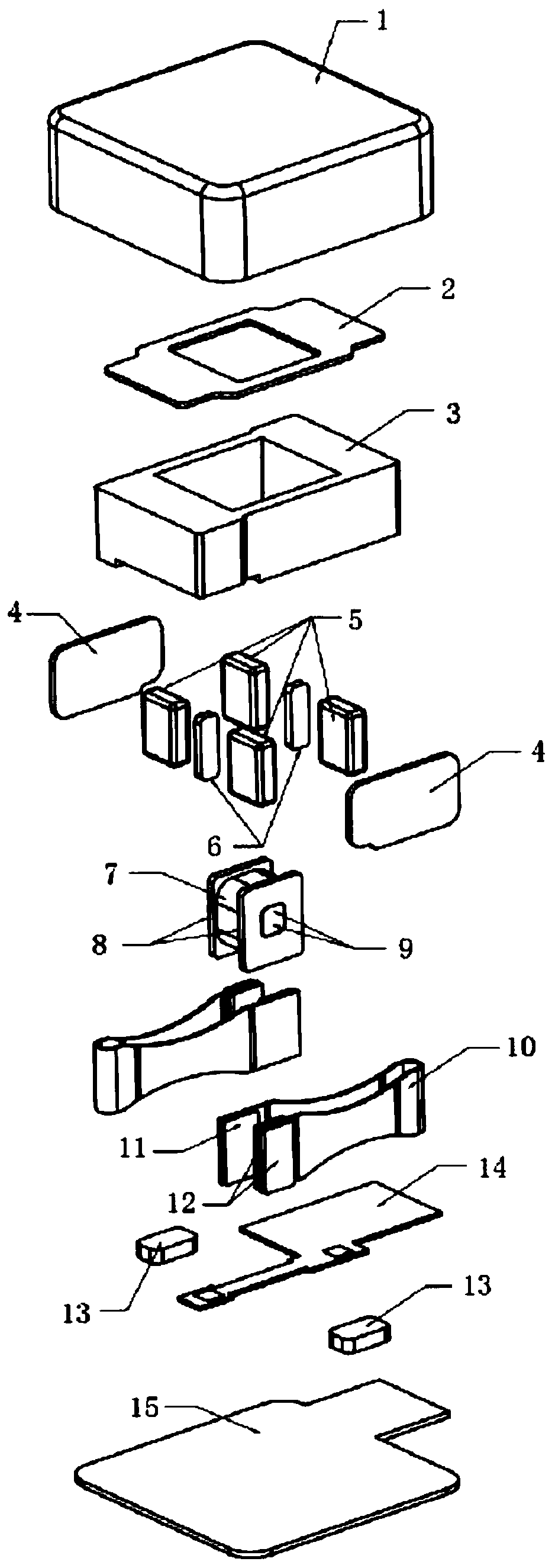

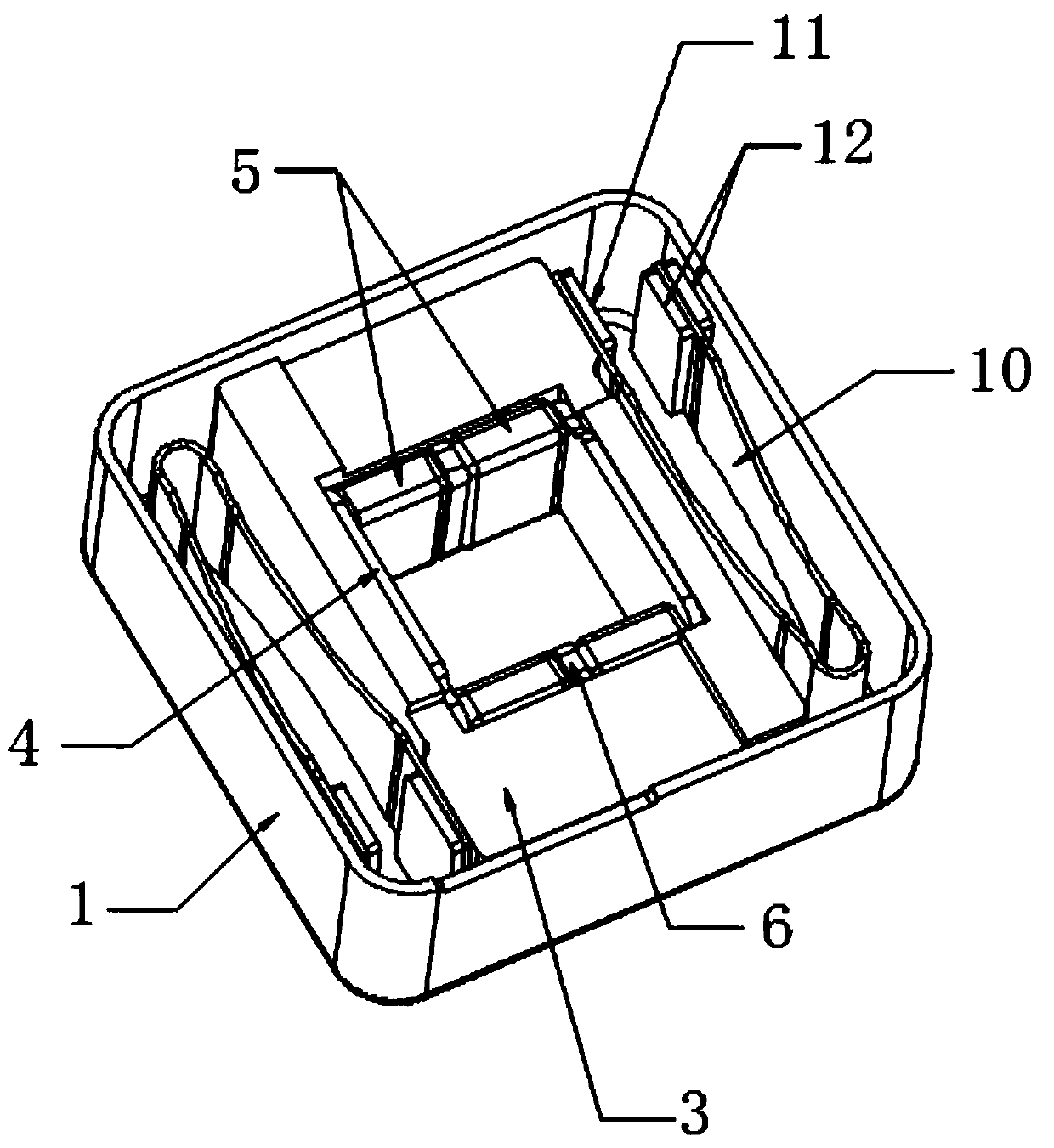

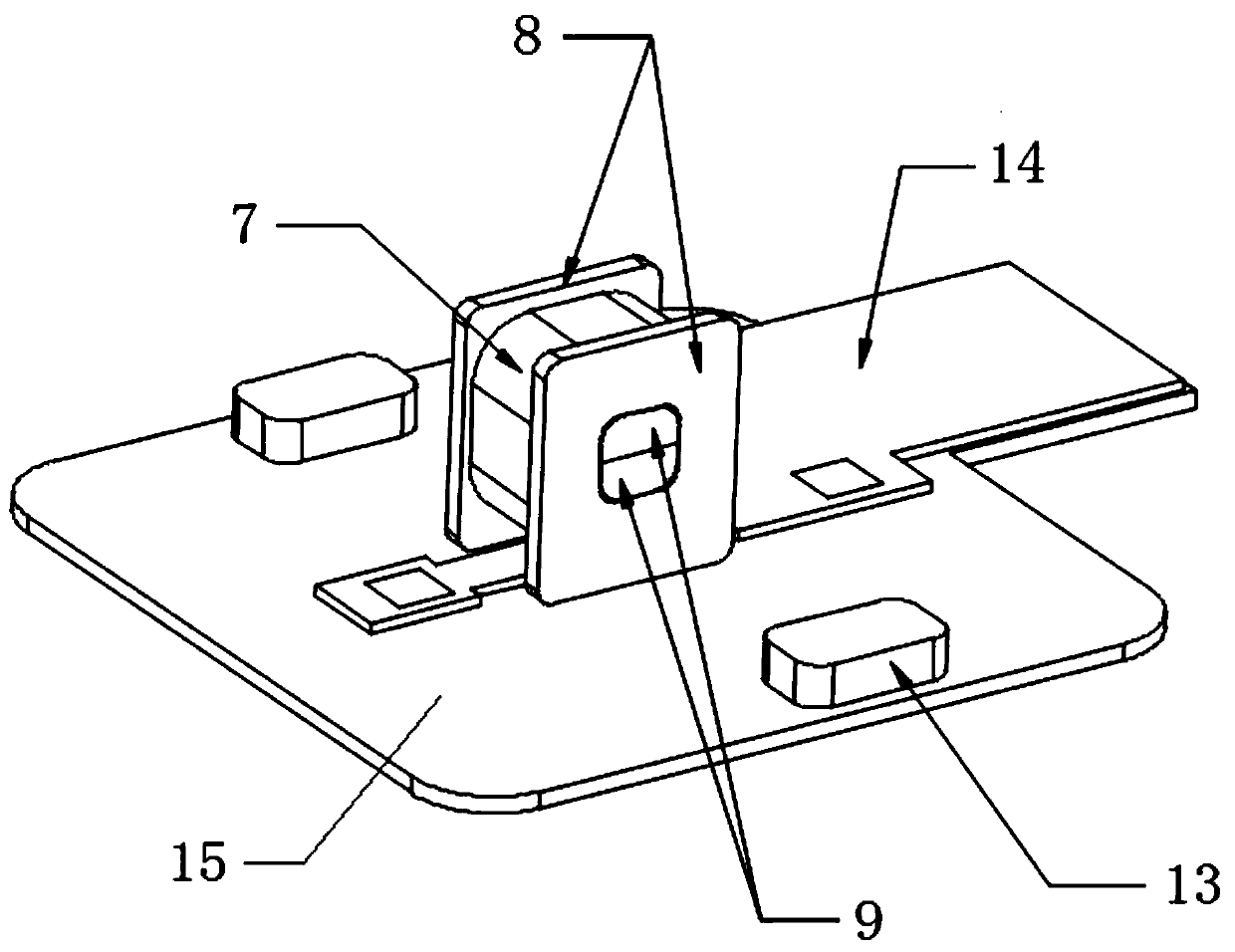

[0039] see Figure 1-6 , the present invention provides the following technical solutions: a horizontal linear motor structure, including a casing 1, a bottom plate 15 is connected to the bottom of the casing 1, a stator assembly is connected to the top of the bottom plate 15, a vibrator assembly is provided inside the casing 1, and the vibrator The assembly includes a mass block 3, a pole piece 4 and a magnetic steel assembly, wherein the opposite sides of the mass block 3 are respectively connected to a magnetic steel assembly, and the two sides of the magnetic steel assembly are connected to a pole piece 4, and the mass block 3 passes through a spring piece 10 Connected with the casing 1, the stator assembly includes a coil 7, an iron core 9 and an FPC circuit board 14, wherein the FPC circuit board 14 is connected above the bottom plate 15, and the coil 7 is arranged above the FPC circuit board 14, and the inside of the coil 7 is provided with There is an iron core 9, and ...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that further, second stoppers 12 are respectively connected to both sides of the connecting arm connecting the spring leaf 10 and the casing 1, and the connecting arm connecting the spring leaf 10 and the mass block 3 is far away from the mass One side of the block 3 is connected with a first block 11 .

[0050] By adopting the above-mentioned technical scheme, the first stopper 11 and the second stopper 12 opposite to the first stopper 11 are used to fix the leaf spring 10, and weld the spring leaf 10 and the mass block 3, the spring leaf 10 and the casing 1 Provide welding flatness, strengthen the firmness of welding, and ensure the consistency of product frequency; the second stopper 12 between the casing 1 and the spring sheet 10 is used to increase the distance between the casing 1 and the spring sheet 10, ensuring The movement spaces on both sides of the spring leaf 10 are consistent.

[0051] Further, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com