A device for making reed contacts

A technology for making devices and electrical contacts, applied in the directions of measuring devices, connections, circuits, etc., can solve the problems of troublesome assembly process, small overall structure, and failure rate of defective products, so as to facilitate the assembly of electrical contacts and reduce the difficulty of installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

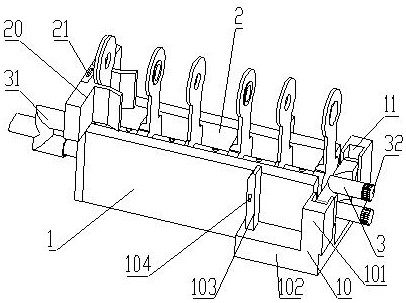

[0046] see figure 1 and image 3 , the present invention provides a dry reed electric contact manufacturing device, the present invention provides a dry reed electric contact manufacturing device, including a base 1, and a clamp assembly, the base 1 is provided with a placement groove 2 for placing an electric contact support structure, When in use, the lower part of the electric contact bracket structure is placed in the placement groove 2, one end of the base 1 is a closed end, and the other end is an open end;

[0047] The inside of the base 1 is provided with a rubber delivery tube 3, which is set horizontally, and the rubber delivery tube 3 corresponds to the electrical contact installation hole reserved at the lower part of the electric contact bracket structure. And the material barrel, the other end is a closed end, and several glue outlet holes are arranged along the axis of the rubber pipe 3, and the glue outlet holes are all opened upwards;

[0048] The clamp comb...

Embodiment 2

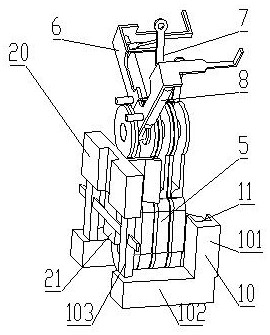

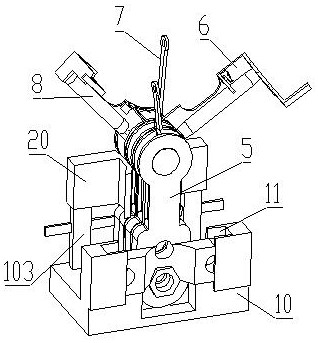

[0076] On the basis of Embodiment 1, the reed electric contact corresponding to the reed electric contact manufacturing device includes a bracket 5, and the upper part of the bracket 5 is provided with a horizontal shaft rod, and the shaft rod is rotated to connect two devices for setting the upper and lower limits of the pressure gauge. One end of the fixed needle 6 and the movable needle 7, the reed switch 8 is fixed on the setting needle 6, and the setting needle 6 is a bent strip plate body, including the bottom plate at the bottom, and the bottom end of the bottom plate rotates with the shaft connection, the middle plate and the upper plate are arranged in sequence above the bottom plate, the plates of the middle plate and the bottom plate are vertical, the plates of the upper plate and the bottom plate are parallel, and the reed switch 8 is fixedly arranged on the plate body of the bottom plate, and the reed switch The axis of 8 is parallel to the plate surface of the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com