Fast Prediction Method of Instability Limit of Steam Turbine Rotor System Based on Shroud Zero Damping

A steam turbine rotor and zero damping technology, which is applied in the testing of machines/structural components, static/dynamic balance testing, measuring devices, etc., can solve problems such as inability to accurately obtain the shroud and the entire rotor system, complex vibration, and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

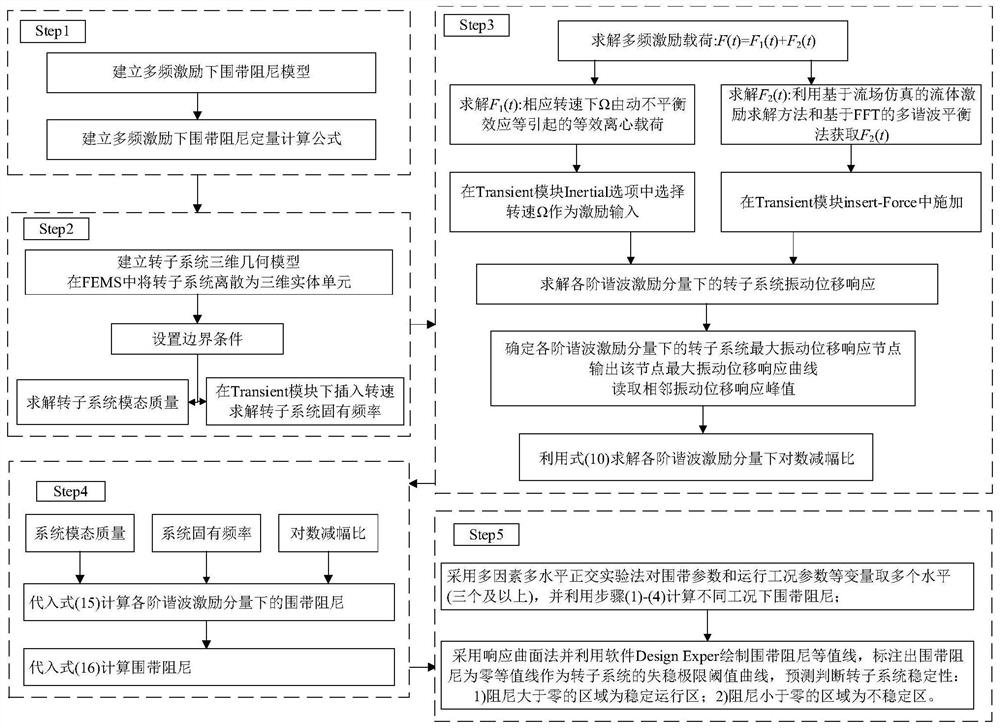

[0028] Embodiment 1. This embodiment provides a rapid prediction method for the instability limit of the steam turbine rotor system based on zero damping of the shroud;

[0029] A rapid prediction method for the instability limit of the steam turbine rotor system based on the zero damping of the shroud, including:

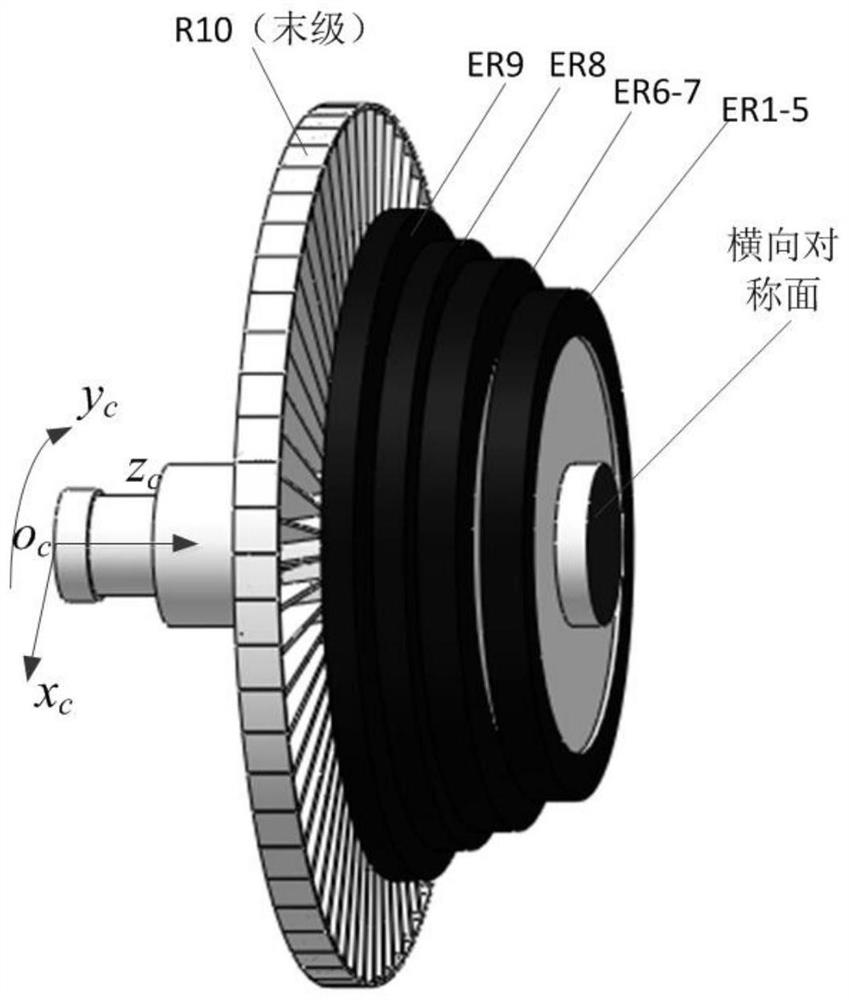

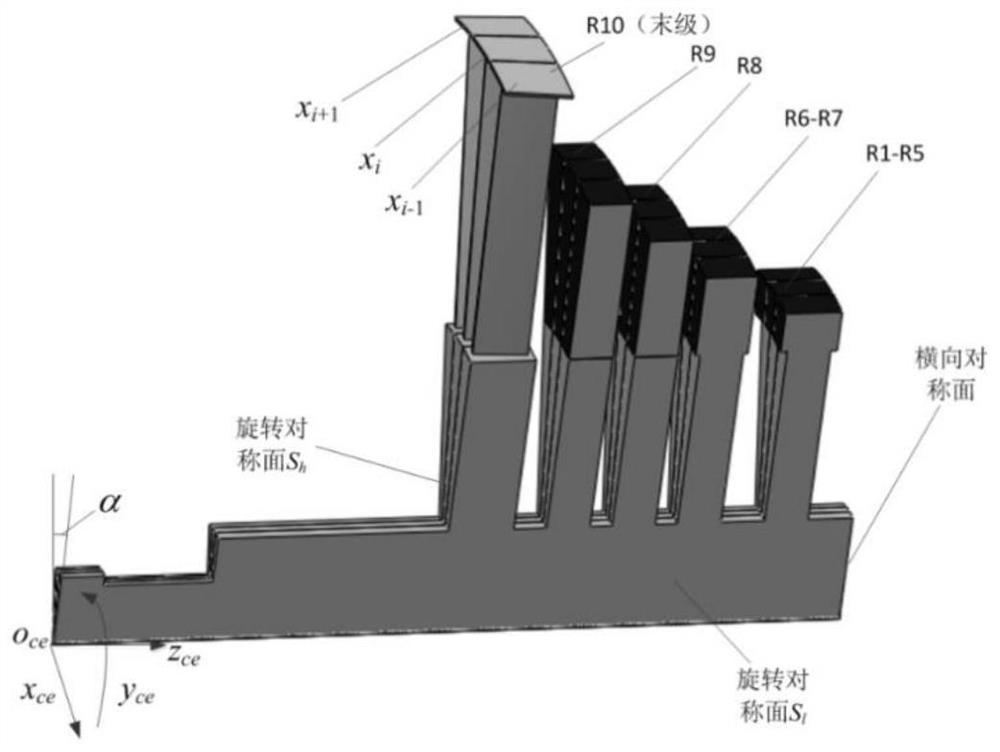

[0030] S1: Construct the equivalent model of the shroud damping of the steam turbine rotor system under multi-frequency excitation and the quantitative calculation formula of the shroud damping;

[0031] S2: According to the structure of the steam turbine rotor system, calculate the modal mass of the steam turbine rotor system and the natural frequency ignoring the shroud damping;

[0032] S3: Use flow field simulation to obtain the multi-frequency excitation force of the steam turbine rotor system under a certain operating condition, convert the multi-frequency excitation force into the superposition of harmonic excitation components of multiple orders and differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com