On-demand defrosting method for air cooler

A cooling fan and air pressure technology, which is applied in household refrigeration equipment, defrosting, applications, etc., can solve problems such as poor heat transfer performance of the cooling fan, frost blocking of the air inlet of the cooling fan, and large temperature fluctuations in the storage room, etc., to achieve energy-saving operation cost, ensure on-demand defrosting, and improve the effect of economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

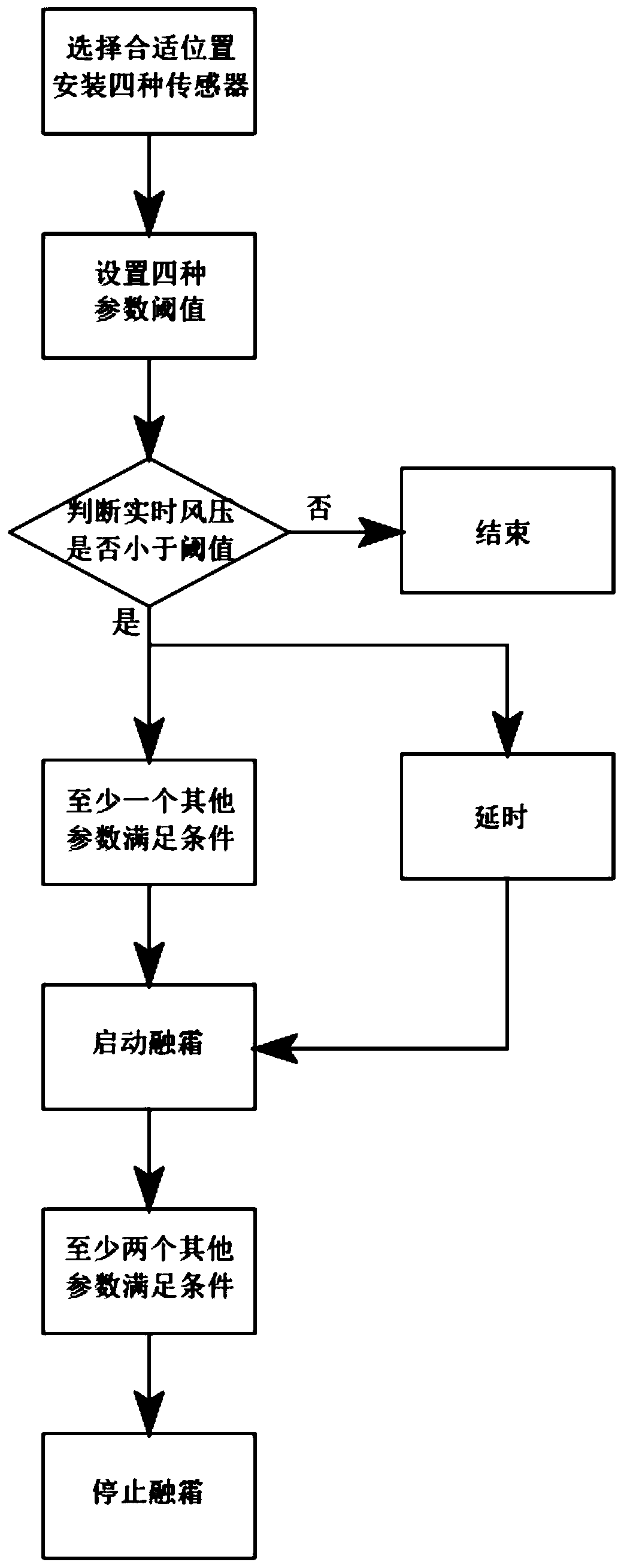

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] When designing the on-demand defrosting in the air cooler, it needs to be determined according to the specific conditions of the air cooler. Since various types of air coolers have different entry points for defrosting, it needs to be determined according to the thickness of the frost layer, absorption The wind pressure in the wind hood, the temperature of the fin surface and the pressure in the air return pipe of the cooling fan are detected and the appropriate entry point and detection position are selected.

[0021] First, select a frost layer thickness threshold for the thickness of the frost layer that needs to be defrosted. When the thickness of the frost layer reaches the frost layer thickness threshold, the defrosting operation will start. The selection of the frost layer thickness threshold is 1 mm to 3 mm. After the test, the test data obtained are: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com