Aluminum alloy window frame convenient to assemble

An aluminum alloy and window frame technology, applied in windows/doors, frame fixing, building components, etc., can solve problems such as laborious and laborious, inconvenient entry, time-consuming and labor-intensive installation, etc., to avoid trouble, increase stability, and increase friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

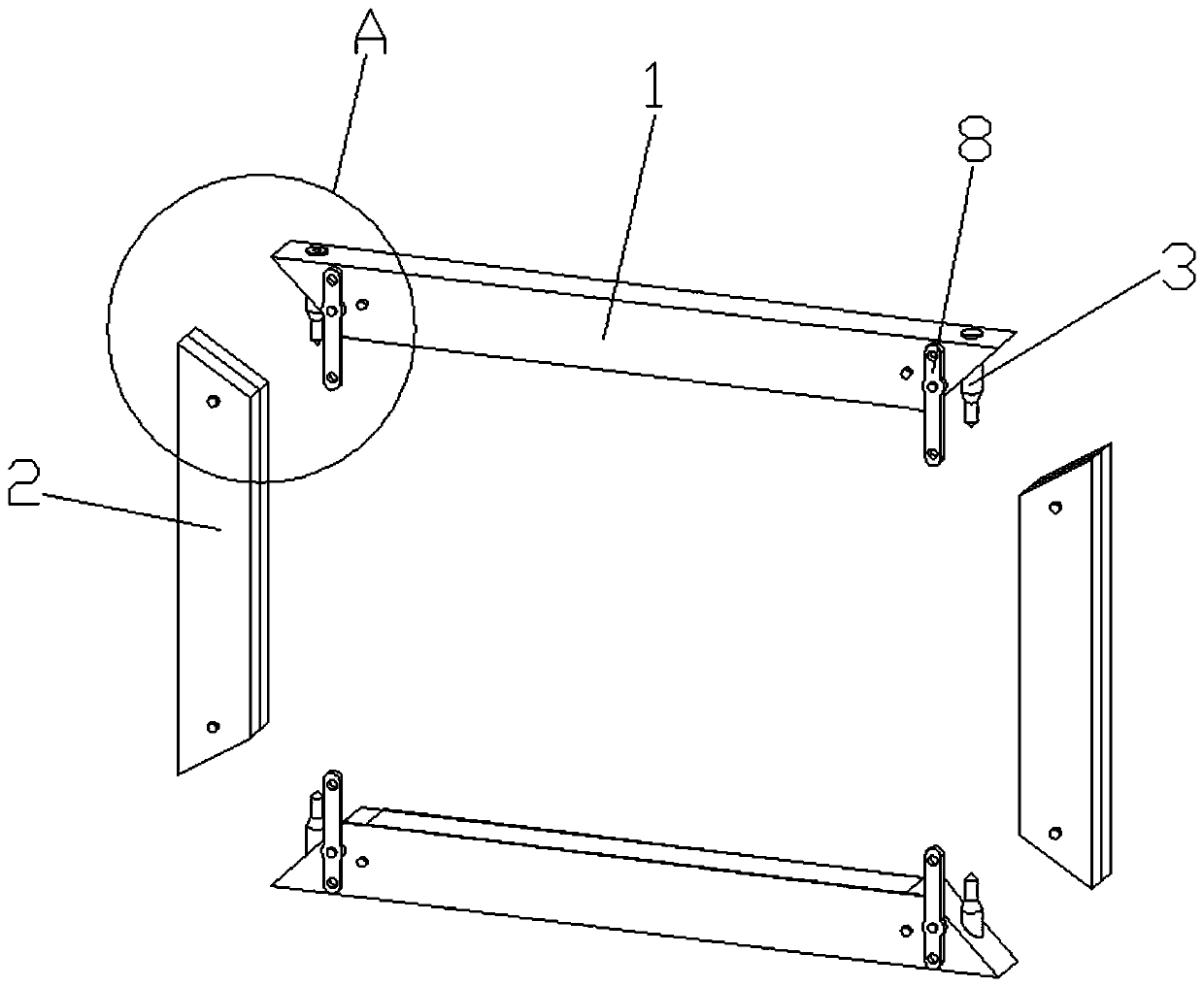

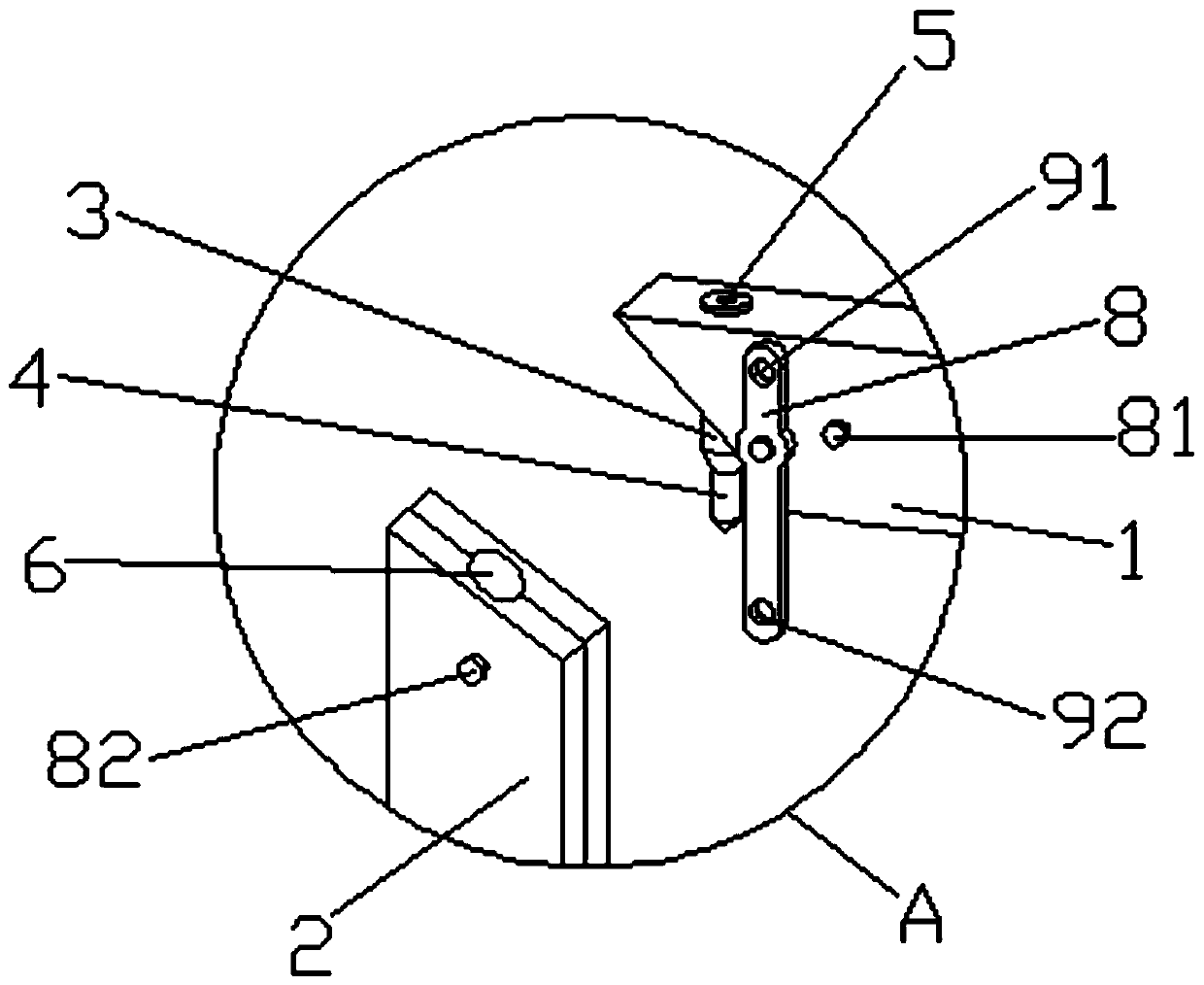

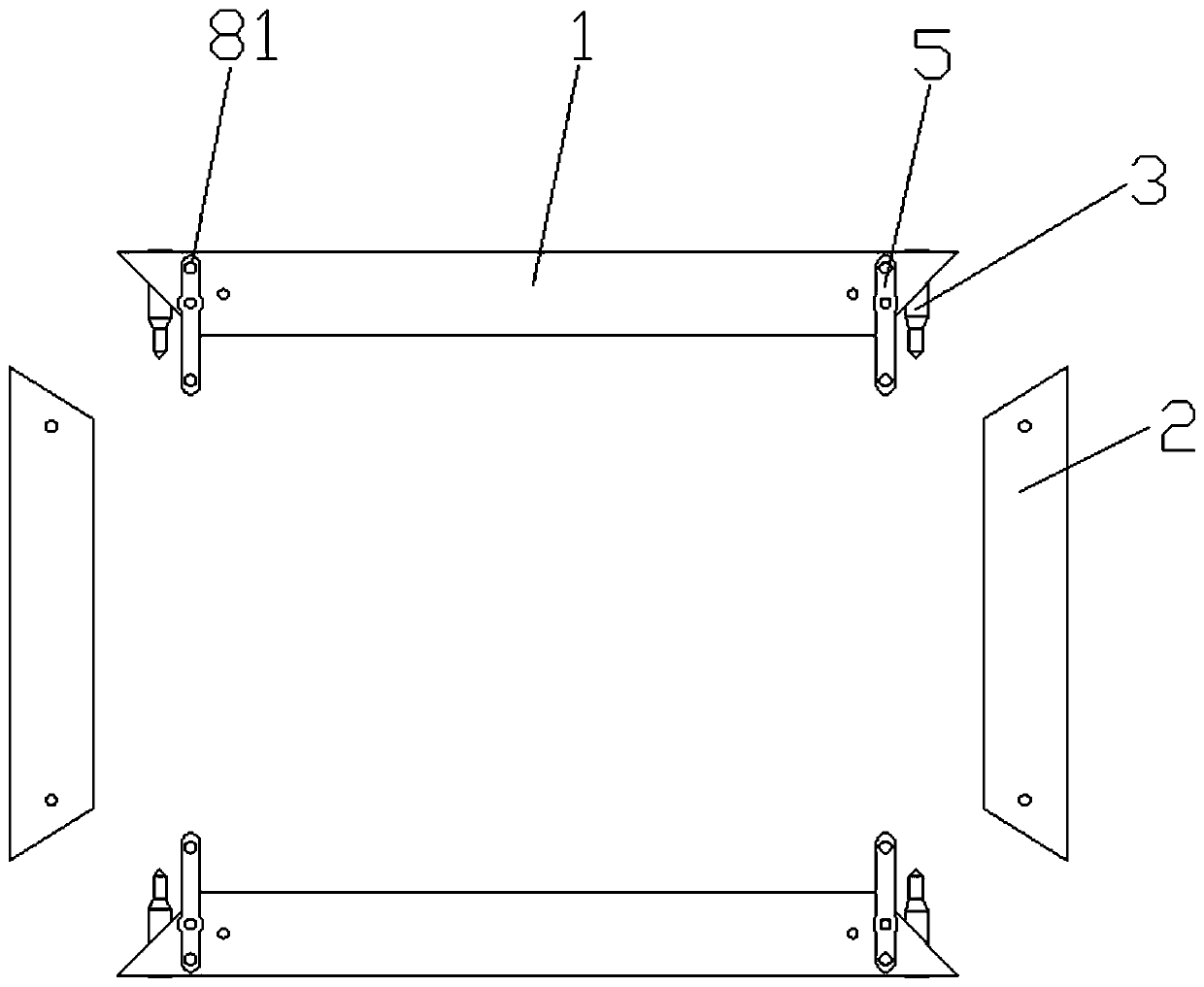

[0027] Such as figure 1 , figure 2 , image 3 As shown, an aluminum alloy window frame that is easy to assemble provided by the present invention includes two first connecting plates 1 and two second connecting plates 2, and the connecting plates 2 are composed of two parts fixed by bolts, which is convenient for splicing and second connecting plates. One connection plate 1 is assembled, and the second connection plate 2 is arranged between two first connection plates 1, and the first connection plate 1 is arranged horizontally, and the second connection plate 2 is vertically arranged, and each first connection plate 1 is connected with The second connecting plate 2 is vertically arranged, and the two ends of each first connecting plate 1 and the second connecting plate 2 are inclined at 45 degrees, and one end of each first connecting plate 1 is connected to one end of the corresponding second connecting plate 2 Correspondingly arranged, two first inserting rods 3 arranged...

Embodiment 2

[0031] On the basis of Example 1, such as Figure 4 and Figure 5As shown: one end of the fixed insertion rod 10 is tapered, and the other end is fixedly connected with a positioning device 12. The positioning device 12 includes a mounting plate 121, and a group of positioning holes 122 arranged in a circular array are arranged on the mounting plate 121. Each positioning A positioning screw 13 is inserted into the hole 122, and the positioning screw 13 includes a screw rod 131. One end of the screw rod 131 is sleeved and bolted to a nut 132. In this embodiment, the nut 132 is fixedly connected to the screw rod 131, and the other end of the screw rod 131 is provided with The expansion hole 133 is provided with a group of coaxial fixing ring grooves 136 in the expansion hole 133, and a fixing cone 134 is arranged in the expansion hole 133, and a group of coaxial fixing rings 135 are arranged on the outside of the fixing cone 134, and the fixing ring 135 Corresponding to the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com