Workover rig wing-room support device

A technology of support device and workover rig, applied in the directions of support device, drilling equipment, earth-moving drilling, etc., can solve the problems of time-consuming and laborious, partial support of oil workover rig, etc., to reduce labor intensity, save time in installation and transportation Effort-saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

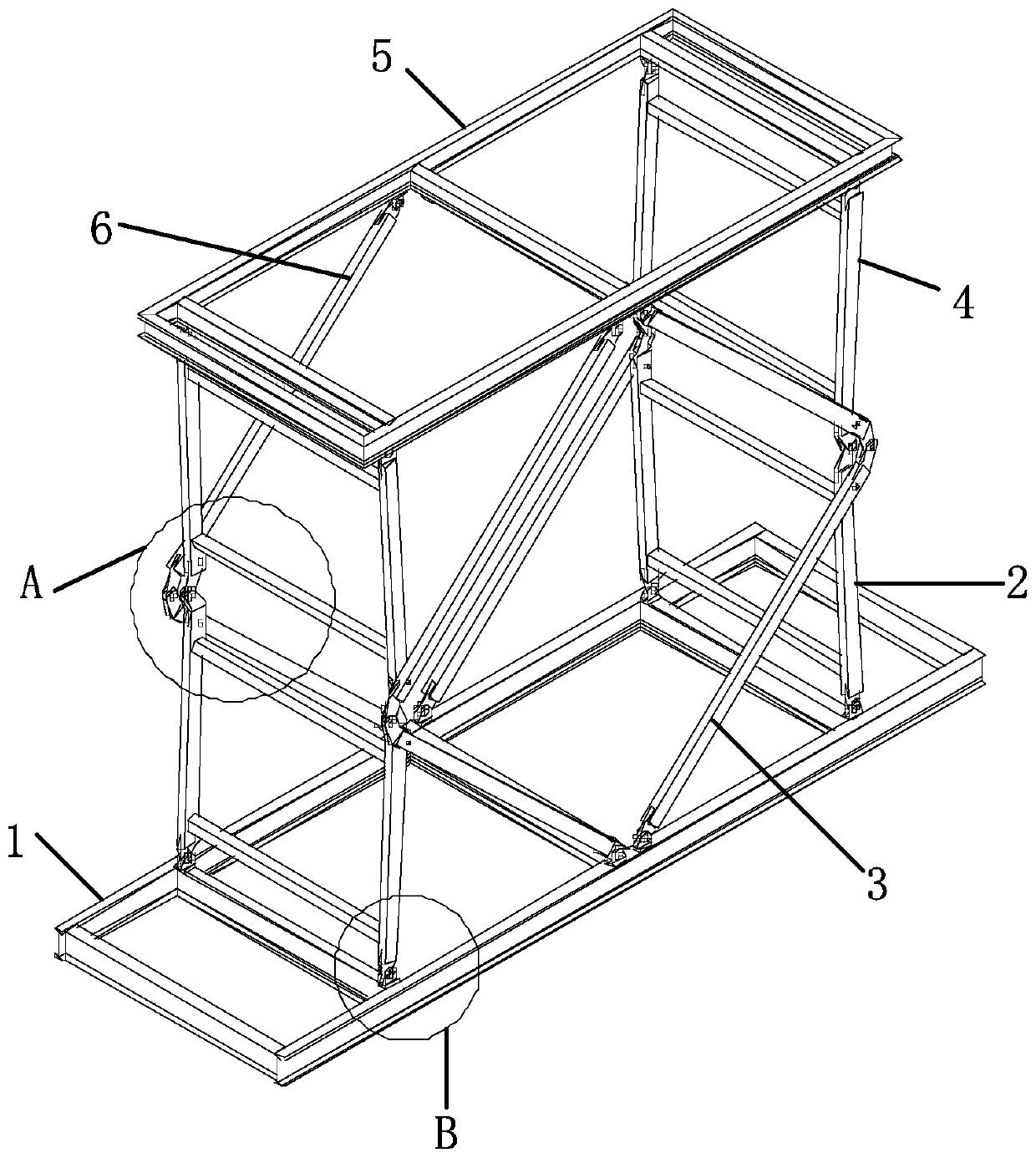

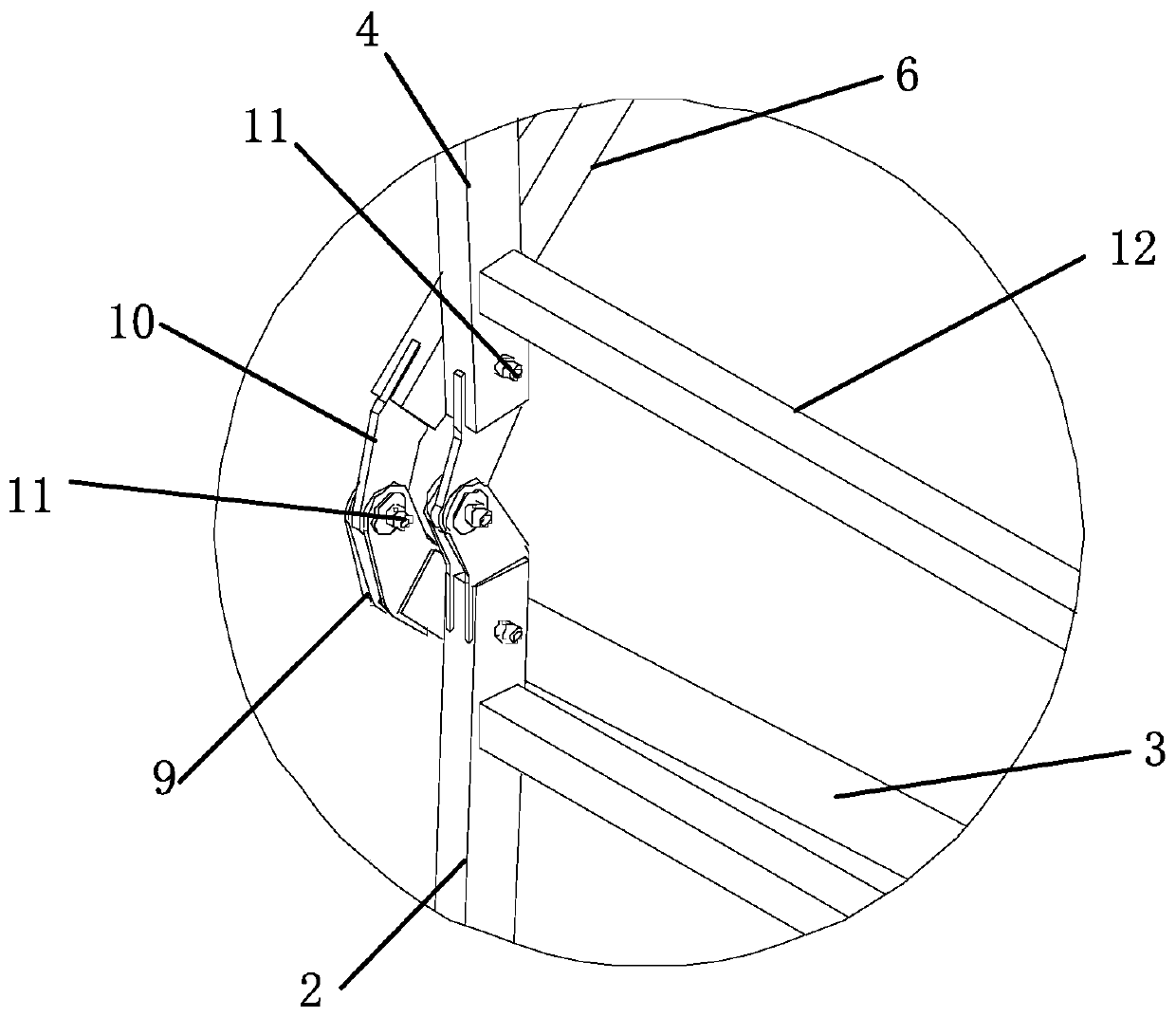

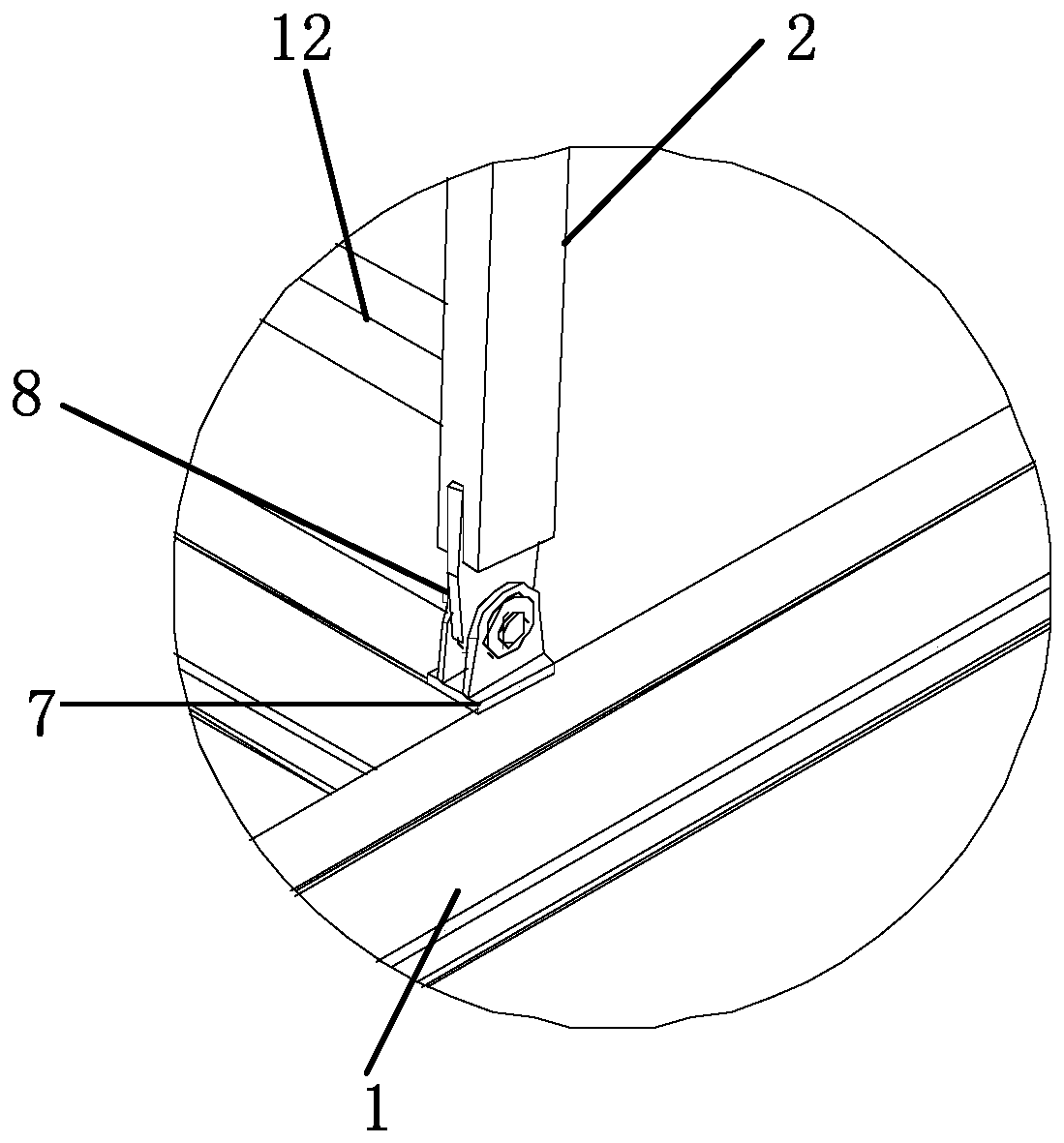

[0024] Such as Figure 1~3 As shown, a workover rig partial room support device disclosed in the present invention includes a support base 1, and eight double-ear connection seats 7 are arranged on the support base 1, and four of the two side edges are used to connect four lower frames Upright column 2, four double lug connecting seats 7 in the middle are used for connecting four pull-down rods 3. Both the lower frame column 2 and the lower rod 3 are connected to the two-ear connection seat 7 through the first connection tongue 8 and the shell pin 11 . And, the other end of the lower rod 3 and the upper end of the lower frame column 2 are also connected together by the shell pin 11 .

[0025] Moreover, eight double-ear connection seats 7 corresponding to the positions of the eight double-ear connection seats 7 on the support base 1 are provided on the partial room base 5 above the partial room support, for correspondingly connecting the upper frame column 4 and the upper tie ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com