Drainage pipeline dredging device adopting horizontal directional drill

A technology of horizontal directional drilling and horizontal directional drilling rig, which is applied to water supply devices, cleaning sewer pipes, waterway systems, etc., can solve the problems of inability to clean up and the low silt removal efficiency of long drainage pipes, and achieve the effect of improving the silt removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

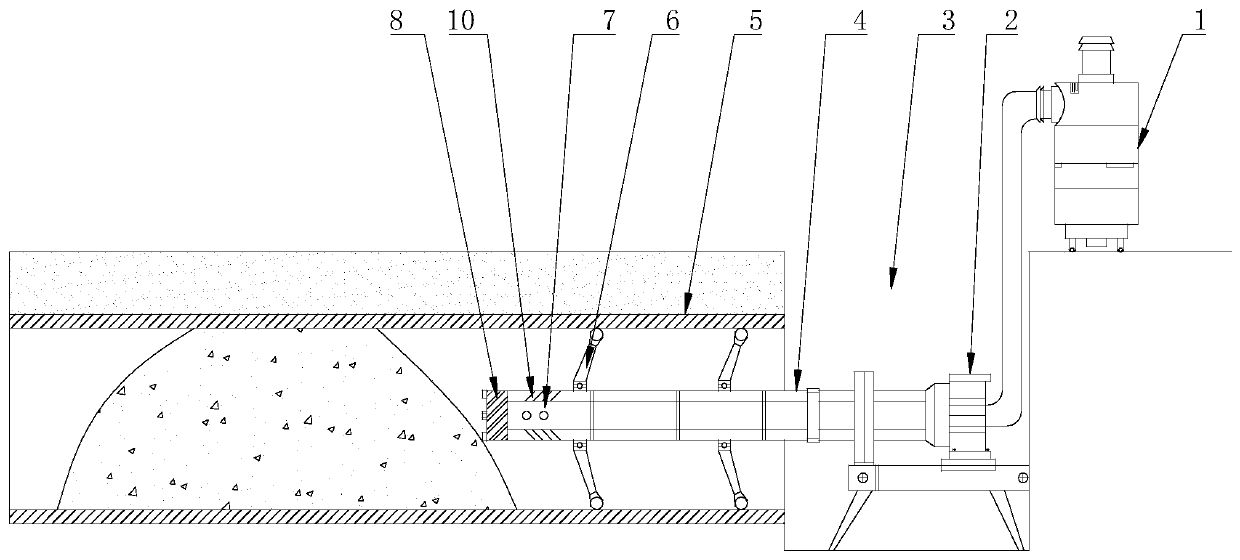

[0016] Please refer to figure 1 , The embodiment of the present invention provides a drainage pipe dredging device using a horizontal directional drill, including a high-pressure pump 1 , a horizontal directional drilling machine 2 , a dredging short 7 and a horizontal directional drill bit 8 .

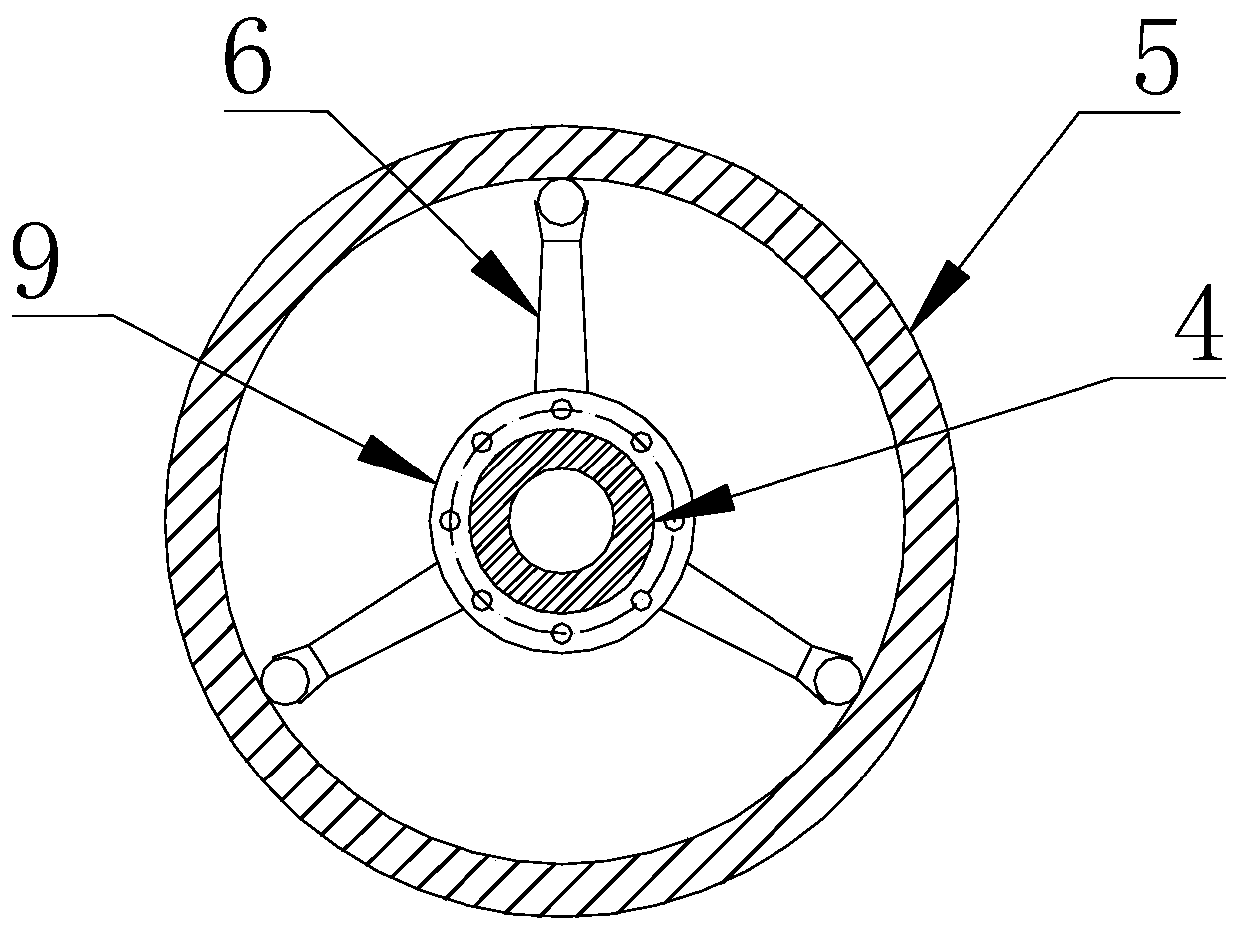

[0017] The horizontal directional drilling machine 2 is placed in an inspection well on one side outside the drainage pipe 5 . In this embodiment, the horizontal directional drilling machine 2 is a micro horizontal drilling machine, and the horizontal directional drilling machine 2 is provided with a hollow drill pipe 4 . The drill pipe 4 adopts a multi-section type, including multi-section drill pipe sections, and all drill pipe sections are detachably connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com