Drainage pipeline desilting device

A technology for dredging devices and drainage pipes, which is used in water supply devices, cleaning sewer pipes, waterway systems, etc., can solve problems such as poor practicability, inability to break dirt, and inability to stir drainage pipes, and achieve the effect of improving efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

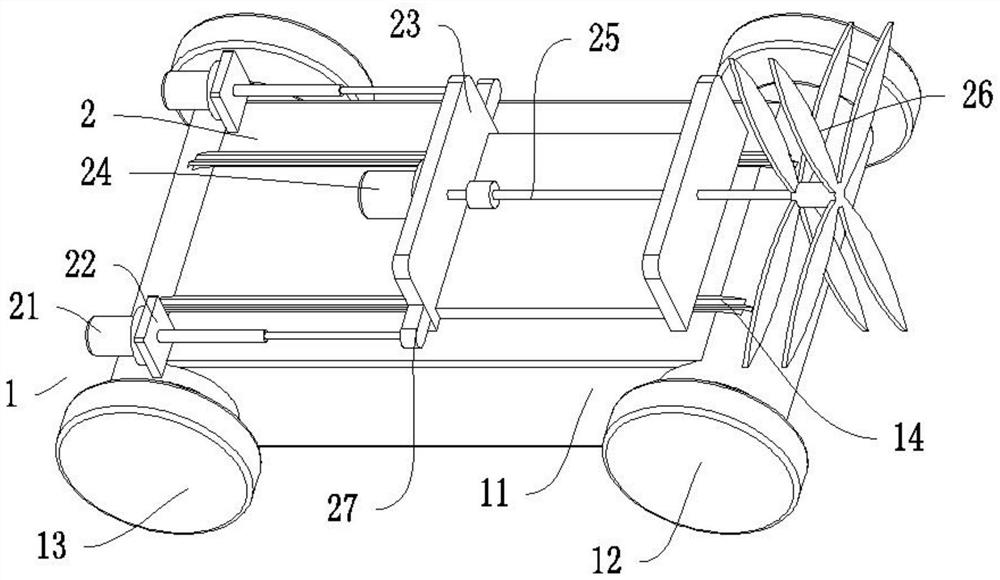

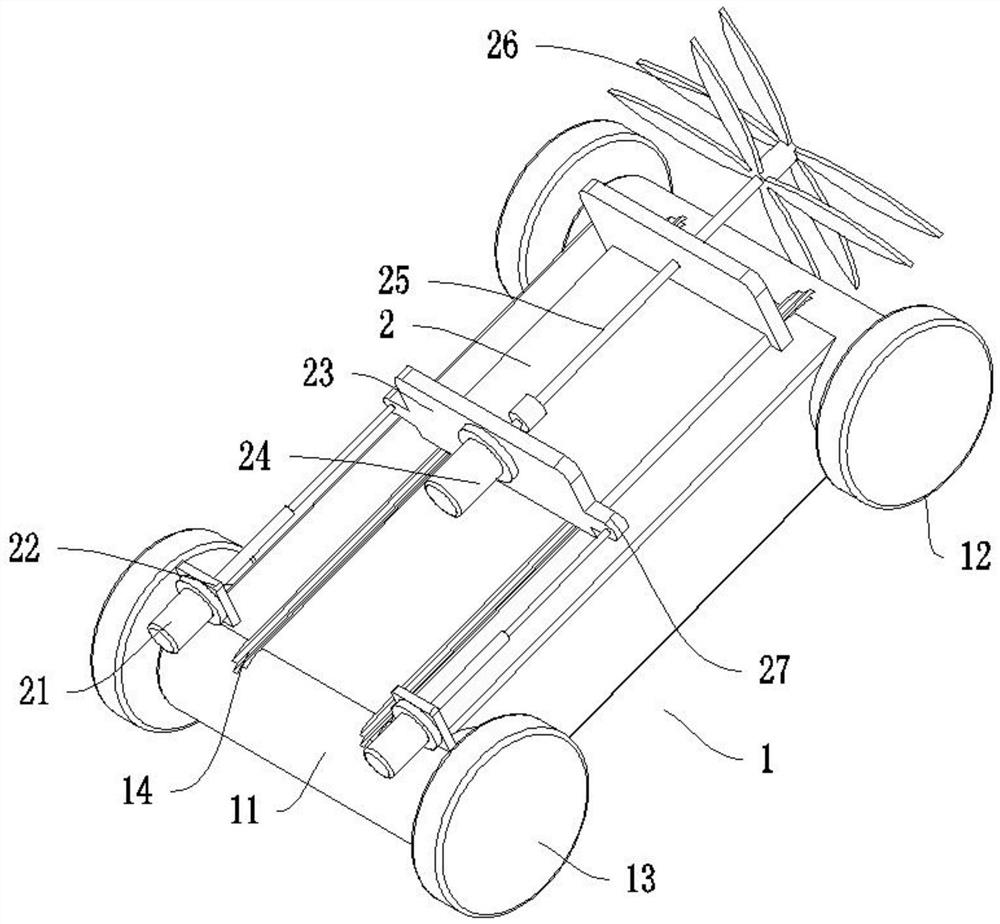

[0025] Such as figure 1 , 2 , 5, the drainage pipe desilting device includes a crawling mechanism 1 for transporting the device to the dredging position as a whole, the crawling mechanism 1 includes a vehicle frame 11, a first wheel 12, and 2 axles are installed on the vehicle frame 11 15. The axles 15 are connected to the frame 11 through bearings. One of the axles 15 is equipped with a first wheel 12 at the front and rear ends, and the other axle 15 is equipped with a second wheel 13 at the front and rear ends. The two axles 15 are symmetrically installed with 2 first bevel gears 16, the inner side of 2 first bevel gears 16 on one side are equipped with second bevel gears 17, the second bevel gears 17 are installed on the two ends of the first rotating shaft 18, the first rotating shaft 18 second bevel The gear 17 is connected by a key, and the second spur gear 111 is installed between the two second bevel gears 17 on the first rotating shaft 18. The second spur gear 111 is...

Embodiment 2

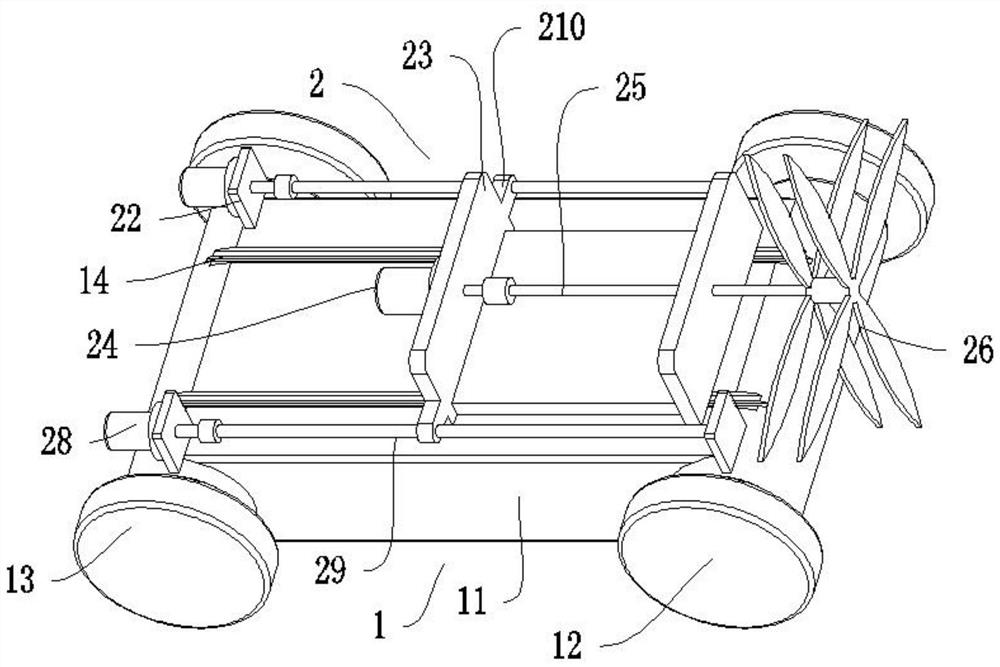

[0028] Such as image 3 , 4 , 5, the drainage pipe desilting device includes a crawling mechanism 1 for transporting the device to the dredging position as a whole, the crawling mechanism 1 includes a vehicle frame 11, a first wheel 12, and 2 axles are installed on the vehicle frame 11 15. The axles 15 are connected to the frame 11 through bearings. One of the axles 15 is equipped with a first wheel 12 at the front and rear ends, and the other axle 15 is equipped with a second wheel 13 at the front and rear ends. The two axles 15 are symmetrically installed with 2 first bevel gears 16, the inner side of 2 first bevel gears 16 on one side are equipped with second bevel gears 17, the second bevel gears 17 are installed on the two ends of the first rotating shaft 18, the first rotating shaft 18 second bevel The gear 17 is connected by a key, and the second spur gear 111 is installed between the two second bevel gears 17 on the first rotating shaft 18. The second spur gear 111 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com