Parallel beating-up and weft insertion mechanism

A weft insertion mechanism and parallel beating-up technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of complex production process, high cost, long cycle, etc., achieve short production cycle, solve variety replacement, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further description will be made below in conjunction with drawings and embodiments.

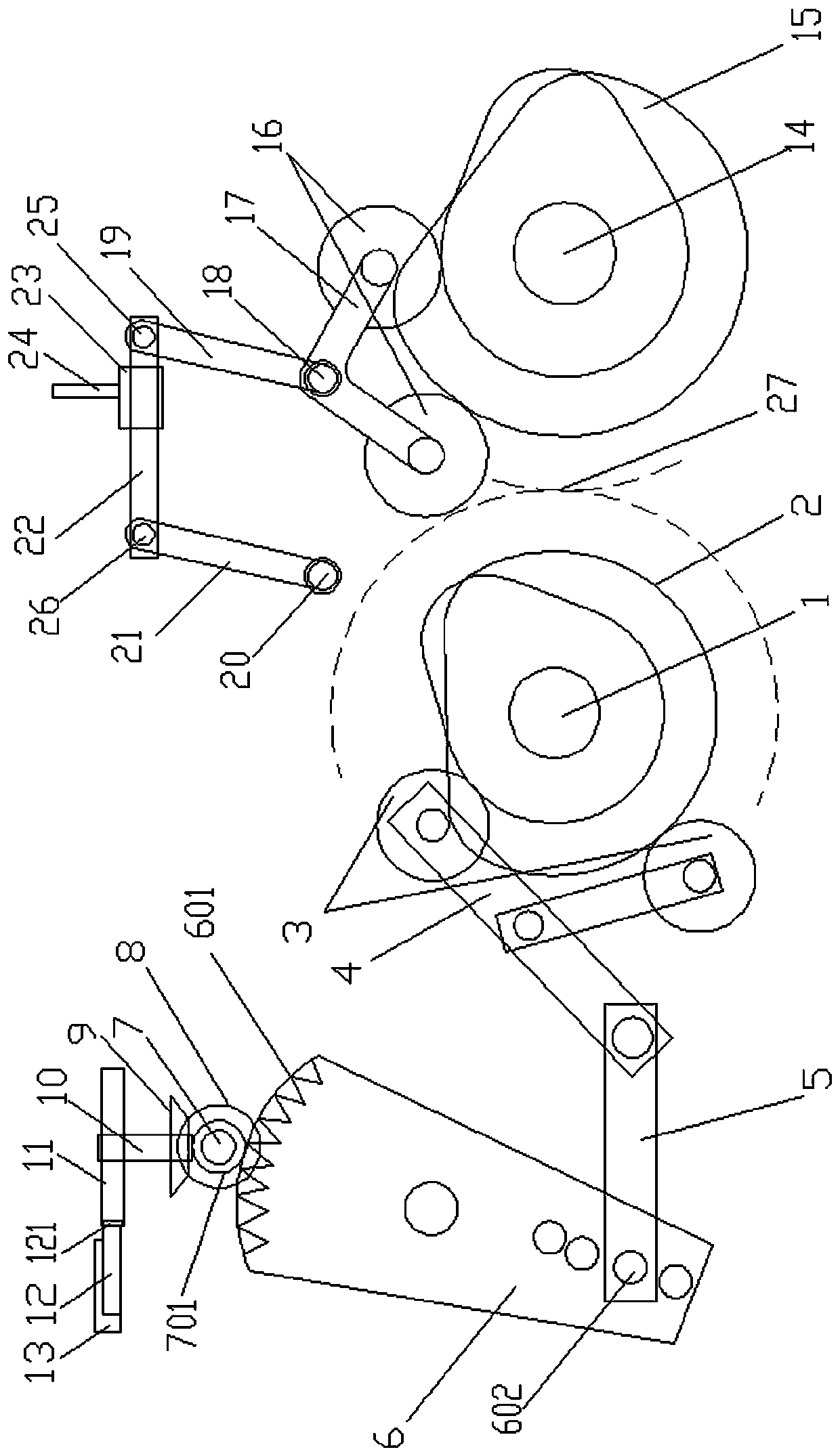

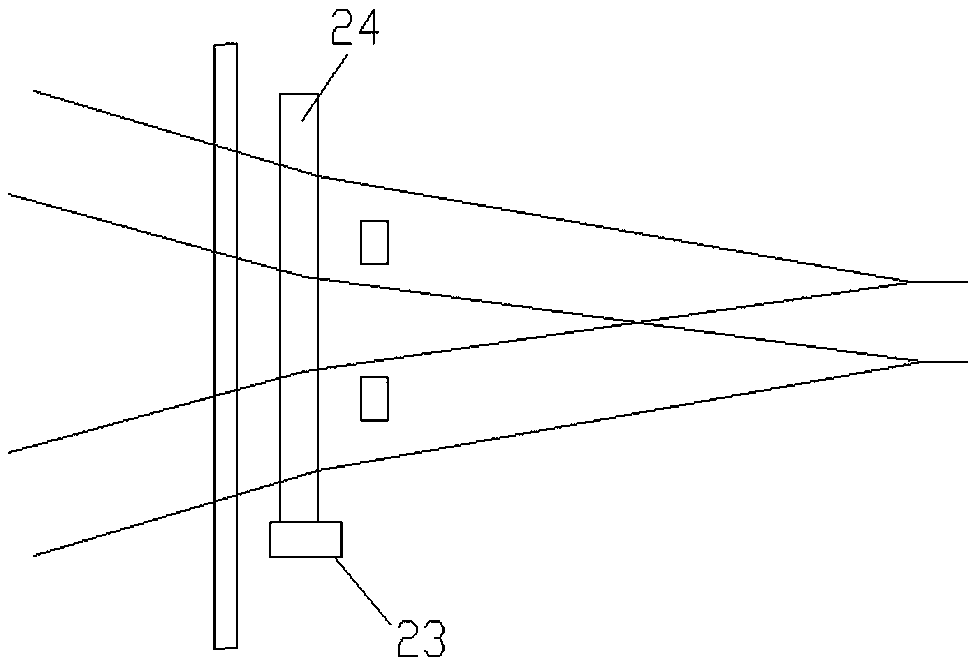

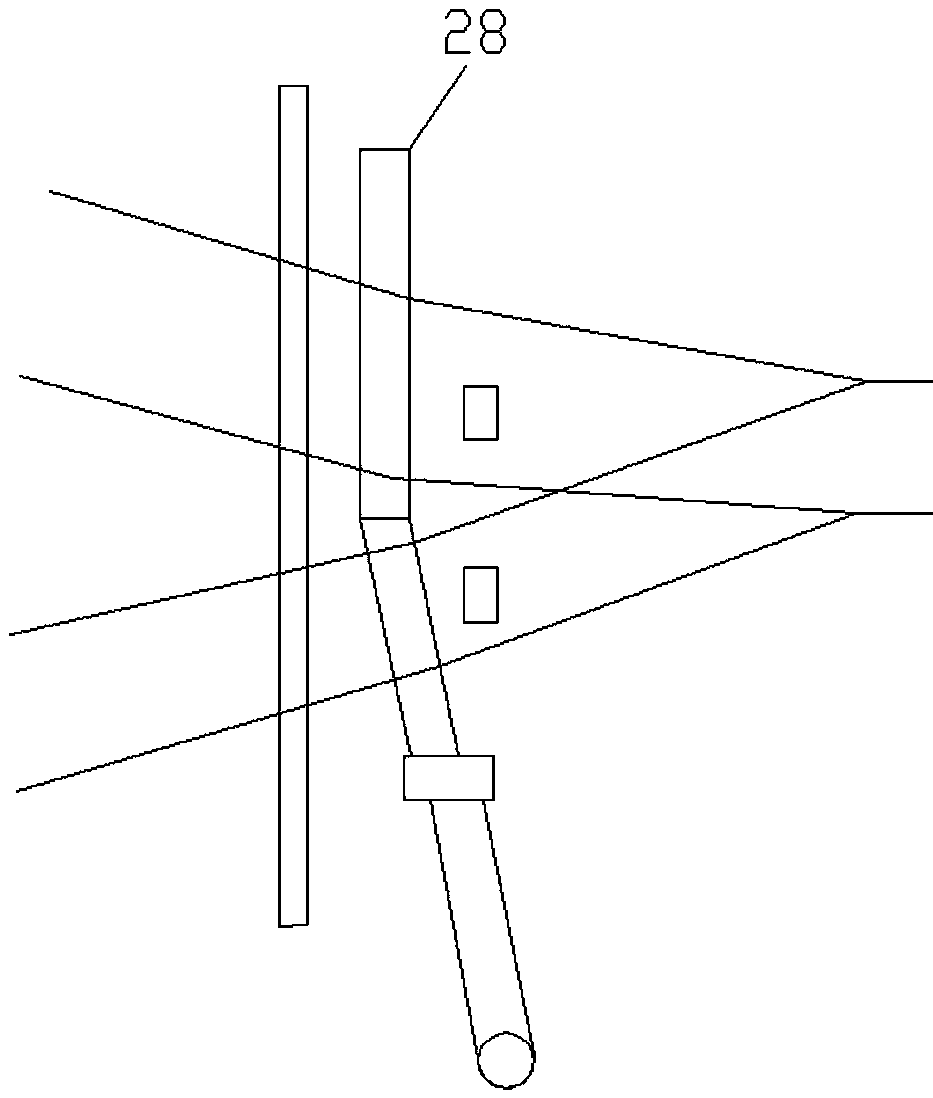

[0018] figure 1 , 2 As shown: a parallel weft beating and weft insertion mechanism includes a weft insertion power shaft 1, a weft insertion conjugate cam group 2, a weft insertion driving rotor 3, a weft insertion swing arm 4, an adjustment connecting rod 5, a weft insertion tooth arm 6, an arc Shaped tooth part 601, pinion shaft 7, tooth part 701, input bevel gear 8, output bevel gear 9, rapier drive shaft 10, rapier drive sprocket 11, rigid rapier 12, strip tooth type 121, rigid rapier Track seat 13, beating power shaft 14, beating conjugate cam group 15, beating drive rotor 16, beating drive swing arm 17, beating drive shaft 18, beating active reed foot 19, beating follower shaft 20 , beat-up follow-up swing arm 21, main follow-up swing arm connecting rod 22, sley 23, steel reed 24.

[0019] The middle part of the weft insertion swing arm 4 is movably hinged on the loom frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com