Low specific gravity high performance wall retaining mud material for medium and long horizontal freezing drilling in silty clay and preparation method

A frozen drilling and silty technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of frozen hole collapse, drill bit deviation, etc., to reduce impact, save cooling capacity, reduce disturbance and The effect of soil erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, a low-specific-gravity high-performance wall protection mud material used for long horizontal freezing drilling in silty clay is composed of basic components and external components. The index of the mud material is: the water loss of the mud is less than 15mL, Specific gravity < 1.05, mud viscosity 20s ~ 50s.

[0038] The basic component is bentonite slurry formed by sodium-based bentonite and water, adding soda ash to the bentonite slurry to make the pH value of the bentonite slurry 9.0-10.0; the external component is composed of polyacrylamide and carboxymethyl cellulose. The basic component is a bentonite slurry formed by sodium-based bentonite and water. Taking water as a reference, the admixture of sodium-based bentonite is 2% to 5% of the mass of water. Adding soda ash to the bentonite slurry makes the pH value of the bentonite slurry 9.0 to 10.0; the external blending component is composed of polyacrylamide and carboxymethyl cellulose, the ad...

Embodiment 2

[0041] In this embodiment, a method for preparing a low-specific-gravity high-performance retaining wall mud material for long horizontally frozen drilling in silty clay comprises the following steps:

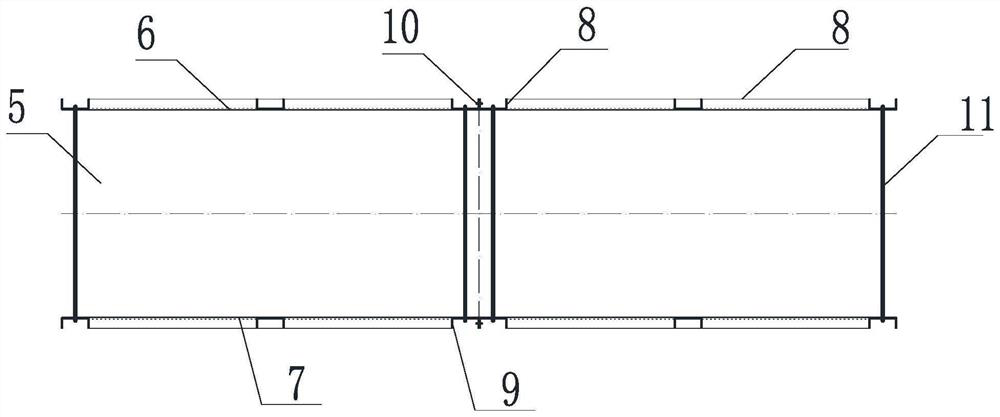

[0042] (1) Determine the main control indicators: In view of the need to form a high-performance mud cake on the mud wall for long horizontal drilling in silty clay: (a) solve the problem of bit deviation at the interface between soft and hard formations during drilling; (b) drill pipe It takes more than 9 hours to pull out and lower the frozen pipe, and the drilling is in a state of underpressure balance (such as figure 1 As shown), it is necessary to form a balanced system with the thin film support body of mud cake and the surrounding small-pore formation, so as to reduce the hole collapse phenomenon that may occur during the pulling out of the drilling tool and the lowering of the frozen pipe.

[0043] From the perspective of experimental research, a test index suitable for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com