Silicon free release film for silicone adhesive tape and preparation method thereof

A release film, non-silicon release technology, used in adhesives, film/sheet release liners, film/sheet adhesives, etc., which can solve problems such as non-conformity, substrate surface damage, silicon pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

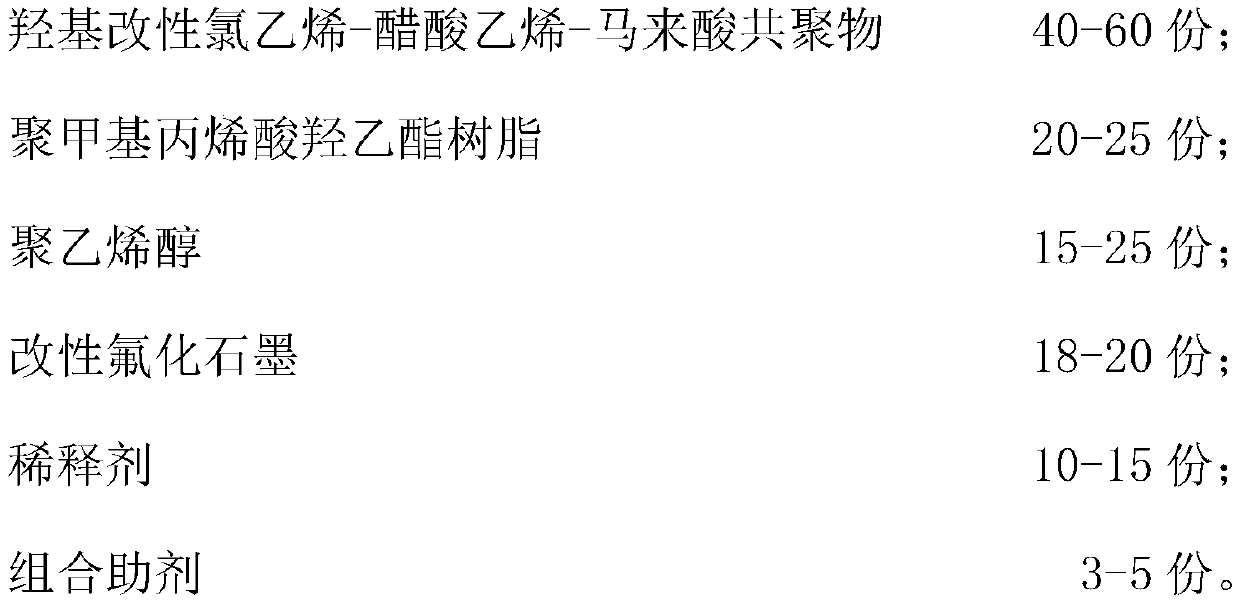

[0024] A silicon-free release film for silicone tape disclosed by the invention comprises a film substrate layer and a non-silicon release layer, and the non-silicon release layer includes the following components in parts by weight:

[0025]

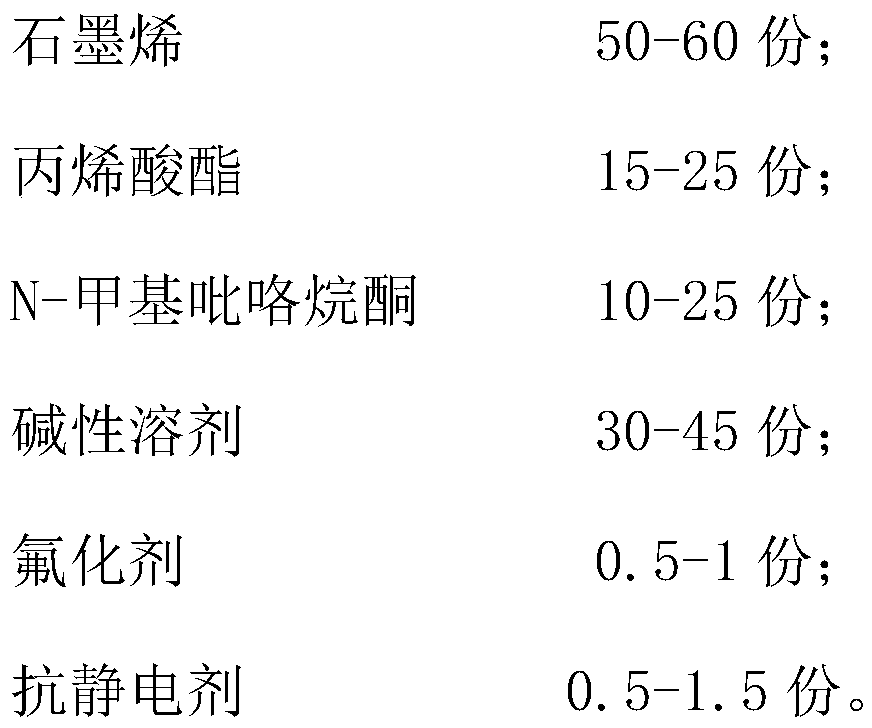

[0026] Further, the preparation method of the hydroxyl-modified vinyl chloride-vinyl acetate-maleic acid copolymer is: add 100 parts of maleic anhydride esterification product and 80 parts of vinyl acetate to the high-pressure polymerization kettle under vacuum conditions, and then separately Add 150 parts by weight of vinyl chloride and 1.2 parts by weight of dispersion stabilizer, stir and heat up to 60°C, then introduce 20 parts of desalted water and 3 parts by weight of initiator potassium persulfate, keep warm for 3 hours, cool down and filter to obtain modified vinyl chloride - vinyl acetate-maleic acid copolymer; wherein, the molecular weight of the modified vinyl chloride-vinyl acetate-maleic acid copolymer is 30,000, and the ...

Embodiment 2

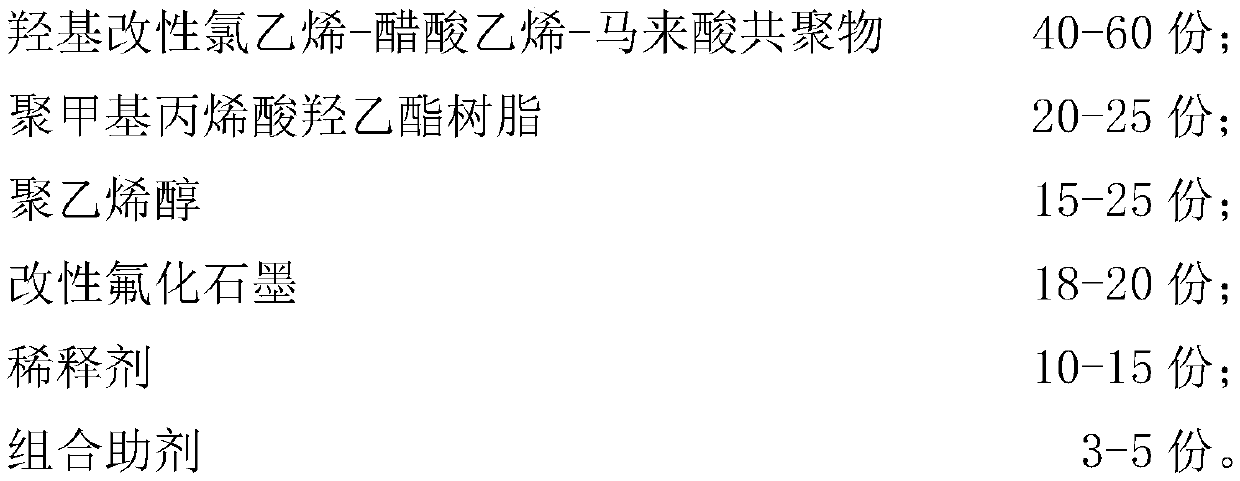

[0038] A silicon-free release film for silicone tape disclosed by the invention comprises a film substrate layer and a non-silicon release layer, and the non-silicon release layer includes the following components in parts by weight:

[0039]

[0040] Further, the preparation method of the hydroxyl-modified vinyl chloride-vinyl acetate-maleic acid copolymer is: add 100 parts of maleic anhydride esterification product and 80 parts of vinyl acetate to the high-pressure polymerization kettle under vacuum conditions, and then separately Add 160 parts by weight of vinyl chloride and 1.8 parts by weight of dispersion stabilizer, stir and heat up to 65°C, then introduce 28 parts of desalted water and 4 parts by weight of initiator potassium persulfate, keep warm for 3 hours, cool down and filter to obtain modified vinyl chloride - vinyl acetate-maleic acid copolymer; wherein, the molecular weight of the modified vinyl chloride-vinyl acetate-maleic acid copolymer is 32000.

[0041]...

Embodiment 3

[0052] The raw materials and process of this embodiment are basically the same as those of Embodiment 1, the only difference is that hydroxyethyl acrylate is changed to hydroxypropyl acrylate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com