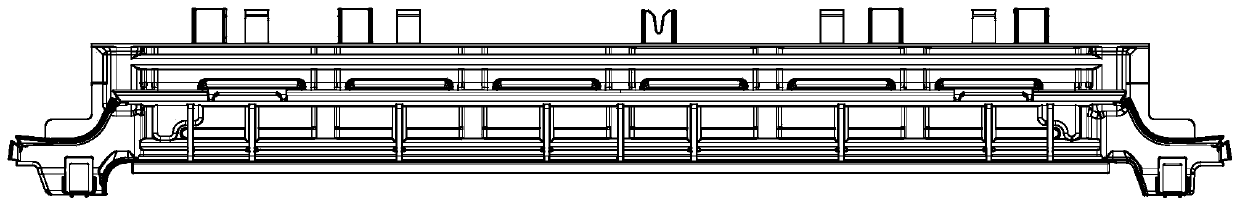

Internal pulling type double-color injection mold

A two-color injection molding and mold technology, which is applied in the field of injection molds, can solve the problems of complex structure of the core-pulling drive mechanism, large amount of product undercuts, and difficult process, and achieve the effect of simple structure, cost reduction and process difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

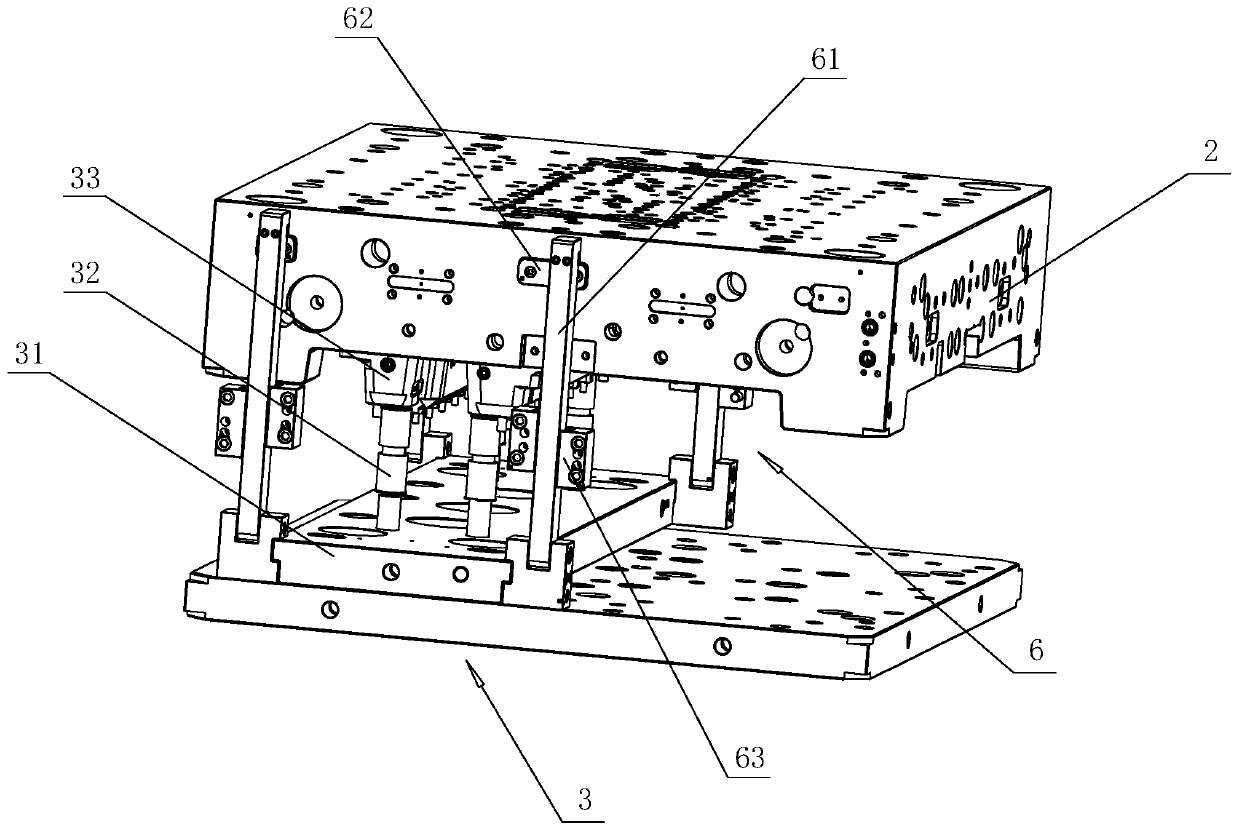

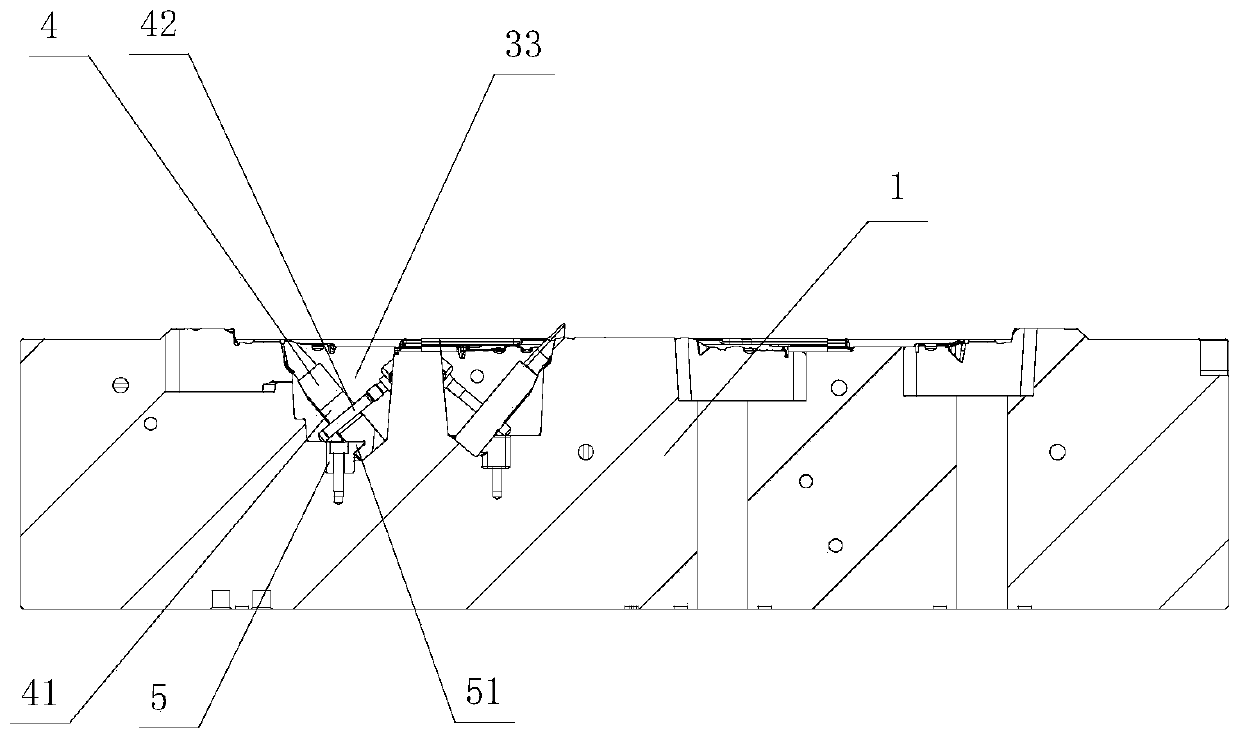

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

[0037] combine Figure 2 to Figure 5 , an internally drawn two-color injection mold, comprising a front mold 1, a rear mold 2, an ejection mechanism 3, a core puller 4, a fixed block 5 and a needle plate driving mechanism 6, and the ejection mechanism 3 is arranged on the side of the front mold 1 , which includes a needle plate 31, a push rod 32 and a top block 33, and the top block 33 is set in the front mold 1 in an inlaid manner. The needle plate 31 is located on the side of the top block 33 away from the back mold 2 , and the top block 33 is fixedly connected with the needle plate 31 through the ejector rod 32 . There are two ejector rods 32 of each ejector mechanism 3, and the two ejector rods 32 are respectively located on both sides of the ejector block 33. One end of the ejector rod 32 is fixedly connected with the ejector block 33, and the other end is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com