A method for biological drying and aeration by recycling waste heat from pyrolysis combustible gas for power generation

A technology of biological drying and pyrolysis gasification, which is applied to chemical instruments and methods, combustion engines, solid waste removal, etc., can solve the problems of long drying time and low temperature of waste heat source of power generation units, and achieve accelerated drying process, shorten the drying time and cycle, and solve the effect of long drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following description is only for disclosing the present invention to enable those skilled in the art to practice the present invention. The embodiments in the following description are only examples, and those skilled in the art can think of other obvious modifications. The basic principles of the invention defined in the following description can be applied to other embodiments, variations, improvements, equivalents and others without departing from the spirit and scope of the invention.

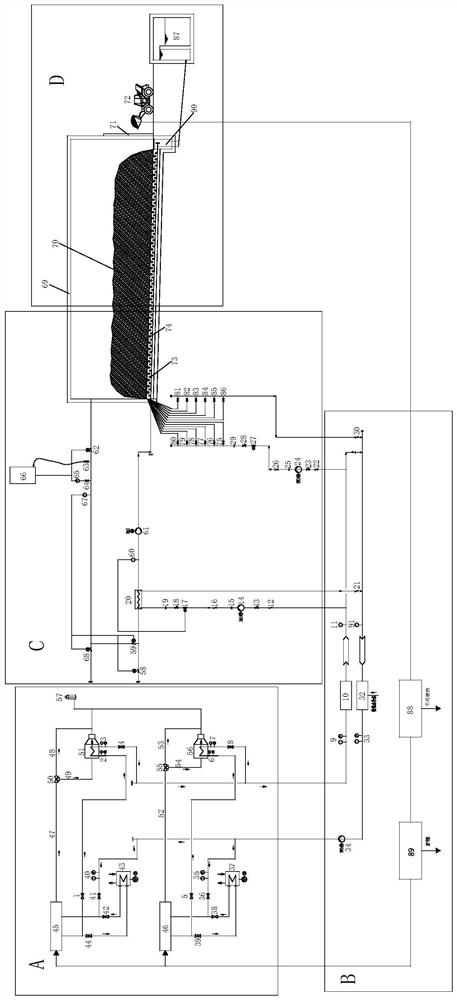

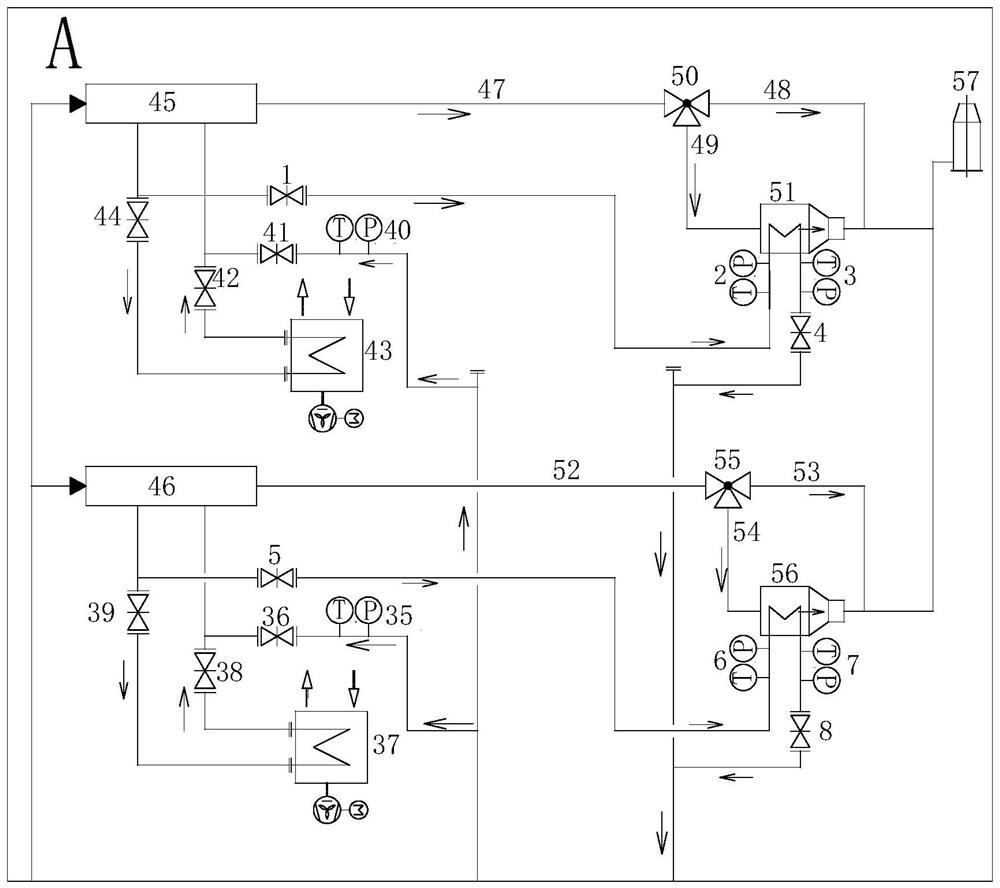

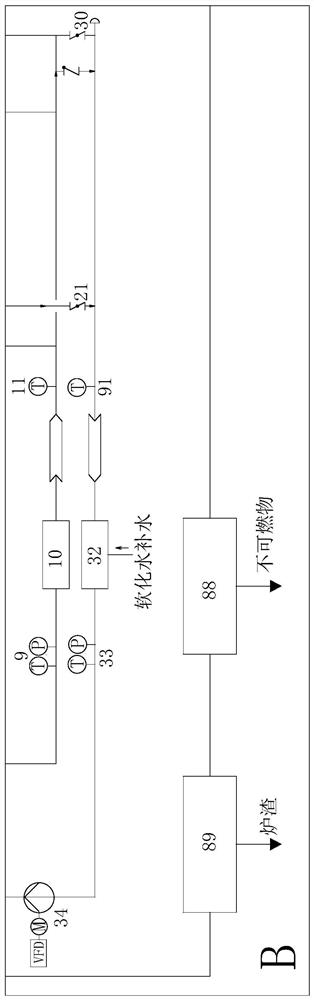

[0027] like Figure 1-5 As shown, the present invention provides a method for recycling the waste heat of pyrolysis combustible gas to generate electricity for biological drying and aeration, which realizes the full recovery and utilization of heat energy and shortens the drying time. Specifically, the method for recycling and utilizing waste heat from pyrolysis combustible gas for biological drying and aeration includes the following steps:

[0028] In the cracking gasificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com