Electrostatic spraying device for electric mosquito swatter production and processing

An electrostatic spraying and electric mosquito swatter technology, applied in electrostatic spraying devices, spraying devices, devices for coating liquid on surfaces, etc., can solve the problems of insufficiently optimized design, single function, simple structure, etc., so as to improve the spraying effect and speed up the Spraying speed, the effect of design optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

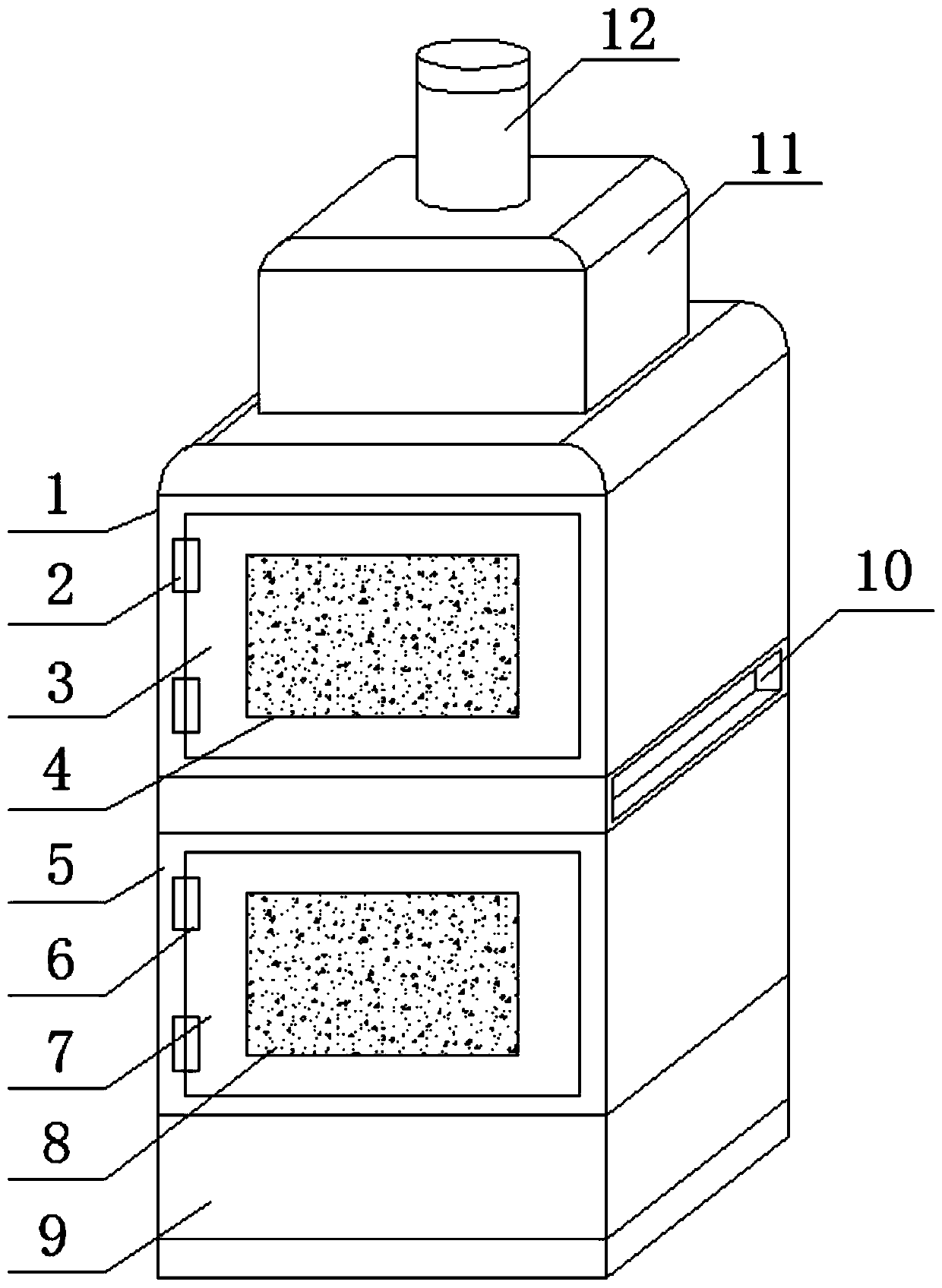

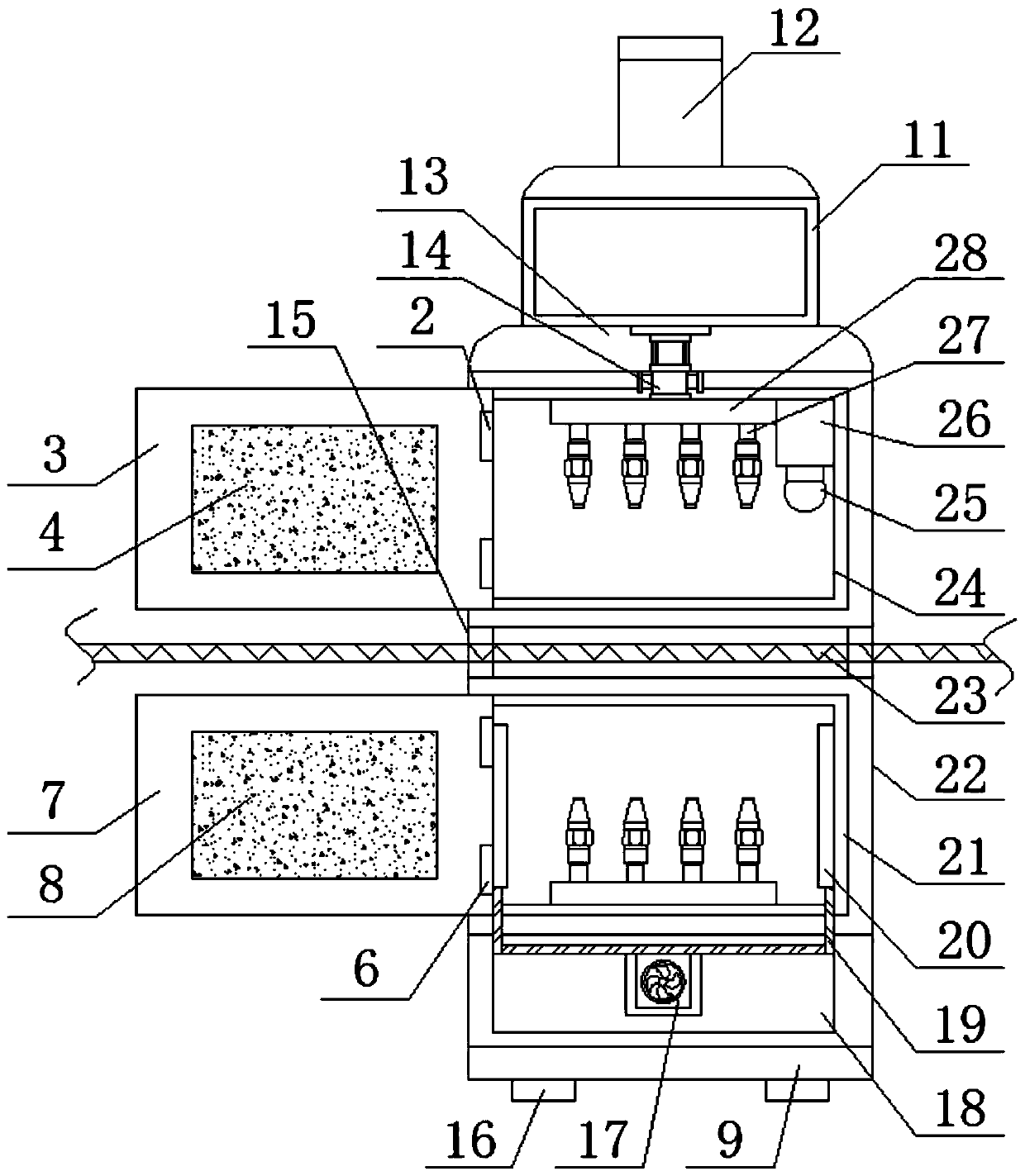

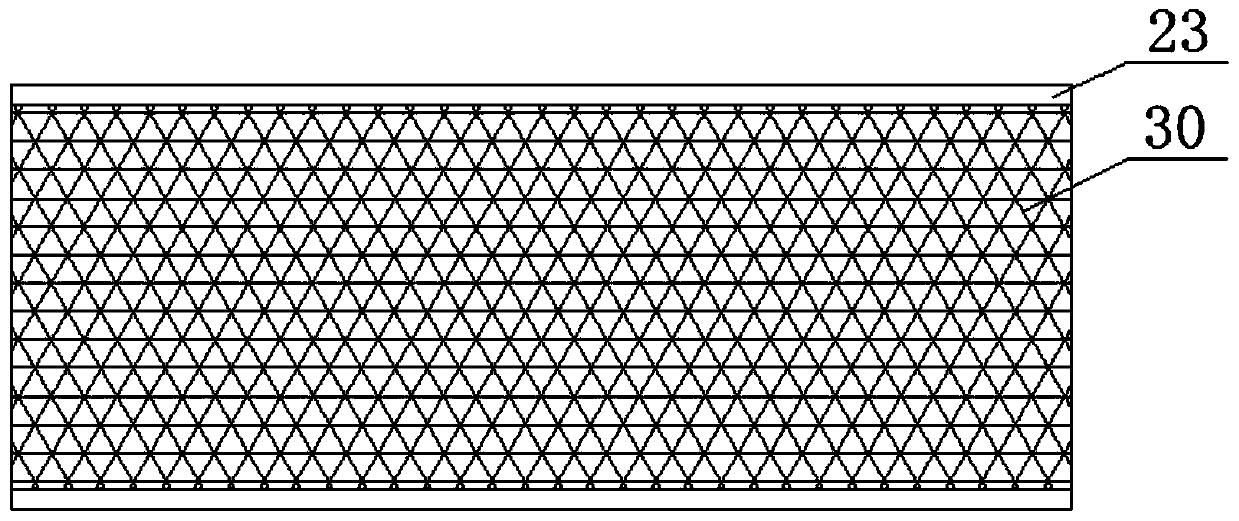

[0028] Such as Figure 1 to Figure 4 As shown, the electrostatic spraying device for the production and processing of electric mosquito swatters in this embodiment includes a body 22. The body 22 includes an upper spraying box 1 and a lower spraying box 5. Through the cooperation of the upper spraying box 1 and the lower spraying box 5, the electric mosquito The rack can be sprayed on both sides during spraying to improve the spraying effect and speed up the spraying speed. The top cover 13 is provided on the top of the body 22, the upper spraying box 1 and the lower spraying box 5 are provided with channels in the middle, and an inlet 15 is provided on one side of the channel. An outlet 10 is provided on the other side of the channel, and a transmission belt 23 is installed through the inside of the channel. The overall enclosed electrostatic spraying device can prevent the spray from leaking and cause certain harm to the staff. The surface of the transmission belt 23 is provid...

Embodiment 2

[0036] The structure of the electrostatic spraying device for the production and processing of the electric mosquito swatter of this embodiment is basically the same as the structure of the electrostatic spraying device for the production and processing of the electric mosquito swatter of the first embodiment. The difference is that the lower spraying chamber 21 is provided with mist suction on both sides The bottom of the mist suction port 20 is fixedly connected with a mist suction tube 19, the other end of the mist suction tube 19 is connected with a mist suction fan 17, the bottom of the mist suction fan 17 is connected with the mist storage chamber 18, and the mist suction fan 17 is connected to the mist suction port 20. The spray in the device can be quickly sucked, and then delivered to the inside of the mist storage chamber 18 through the mist suction pipe 19 (see Figure 5 ).

[0037] Specifically, the upper spraying box 1 is rotatably connected with the upper spraying bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com