Intelligent pulse blowing controller for bag type dust collector

A bag-type dust collector and pulse jet technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of cumbersome long-distance wiring, the need for wiring, and no data communication, and eliminate the need for wires. Aging, eliminating the need for complicated wiring, and the effect of convenient work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

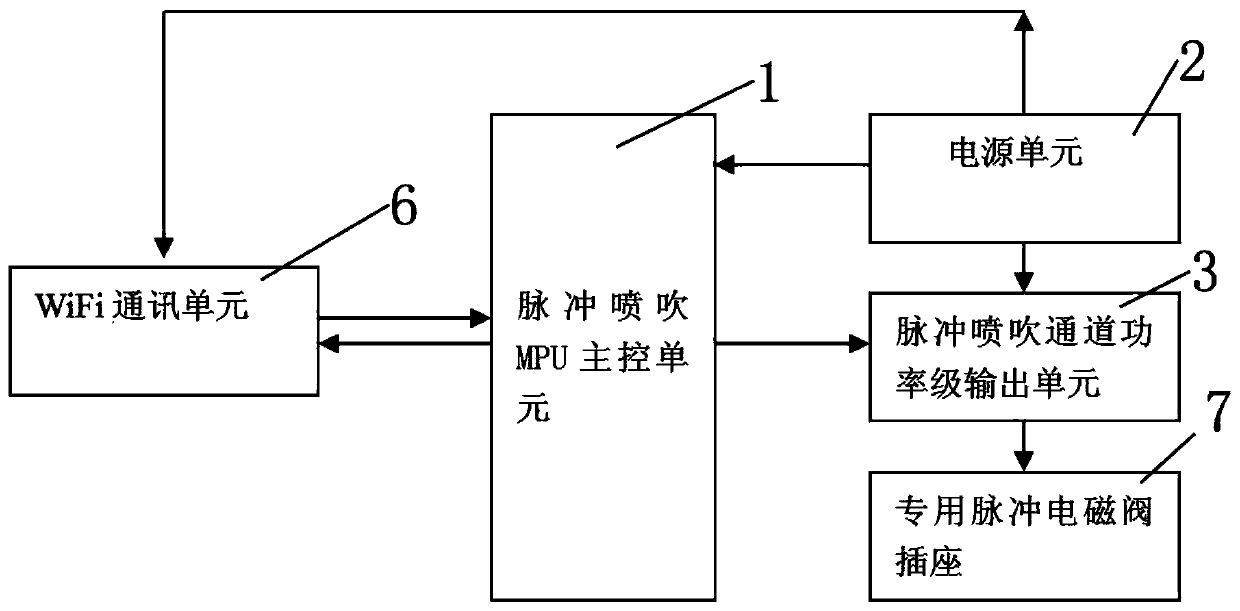

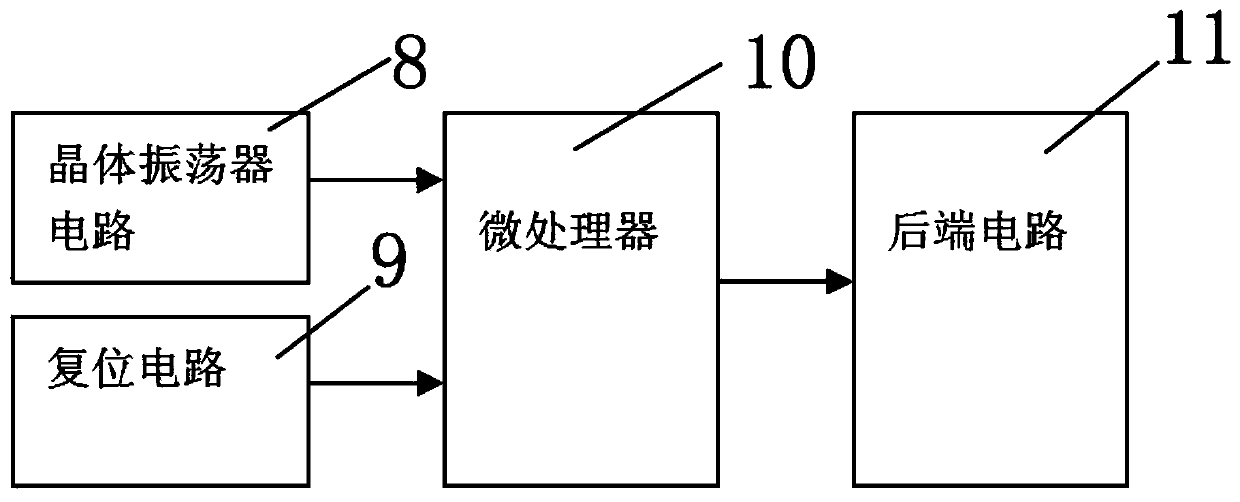

[0024] like Figure 1-5 As shown, an intelligent pulse injection controller for a bag filter disclosed in this embodiment includes a pulse injection MPU main control unit 1, a power supply unit 2, a pulse injection channel power level output unit 3, and a wireless communication unit. The power supply unit 2 is electrically connected with the pulse injection MPU main control unit 1, the pulse injection channel power level output unit 3 and the wireless communication unit respectively, and the wireless communication unit is bidirectionally connected with the pulse injection MPU main control unit 1, so The wireless communication unit described above is a Zigbee communication unit 5 or a WiFi communication unit 6. When the wireless communication unit is a WiFi communication unit 6, the power level output unit 3 of the pulse injection channel is also electrically connected to the bag filter. The pulse solenoid valve socket 7 that the pulse solenoid valve plugs in.

[0025] Further...

Embodiment 2

[0034] like Figure 6-9 As shown, the general structure of an intelligent pulse injection controller for bag filter disclosed in this embodiment is the same as that in Embodiment 1, except that the wireless communication unit is a Zigbee communication unit 5 .

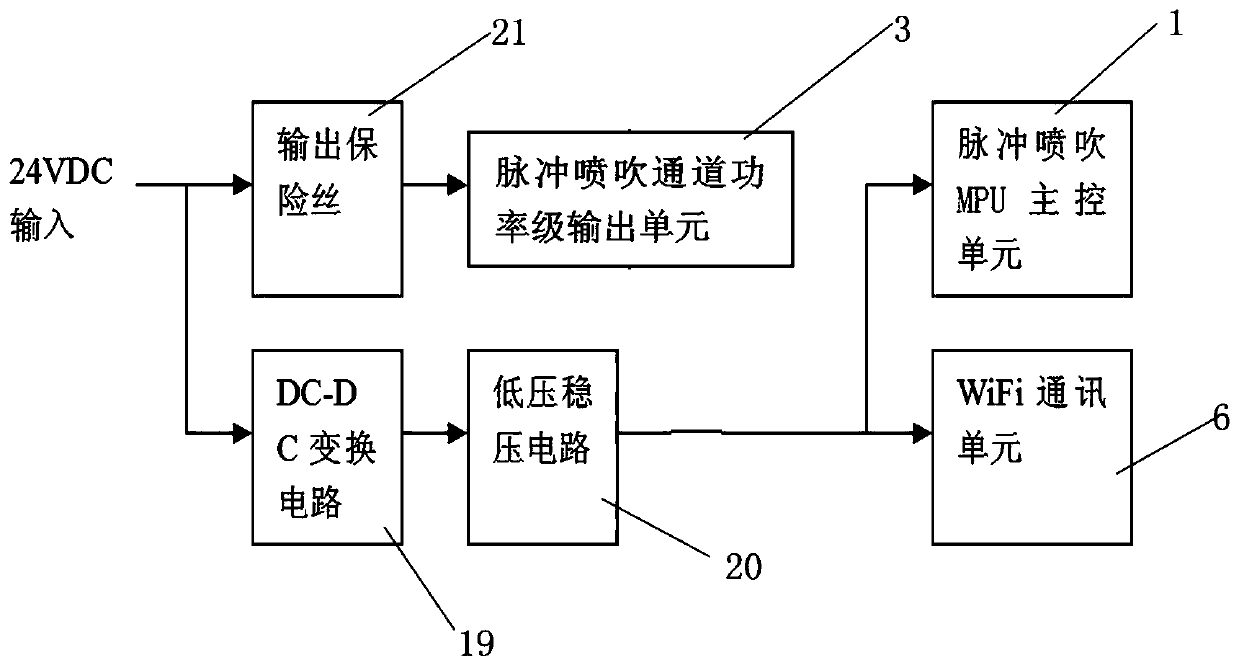

[0035] Wherein, further, the power supply unit 2 includes an input power supply, an output fuse 21, a DC-DC conversion circuit 19 and a low-voltage stabilizing circuit 20, the input power supply is electrically connected to the pulse injection channel power stage output unit 3 through the output fuse 21, The input power supply is AC voltage or 24V DC voltage. When the input is 24V DC voltage, the 24V DC voltage is directly electrically connected to the pulse injection channel power stage output unit 3 through the output fuse 21, and the 24V DC voltage is also directly connected in turn. It is electrically connected with the DC-DC conversion circuit 19 and the low-voltage stabilizing circuit 20, and the output of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com