An industrial bag filter

A bag filter and industrial technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as troublesome maintenance, low dust cleaning efficiency, and heavy dust bag maintenance and replacement workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and To facilitate its practice, but not as a limitation of the invention.

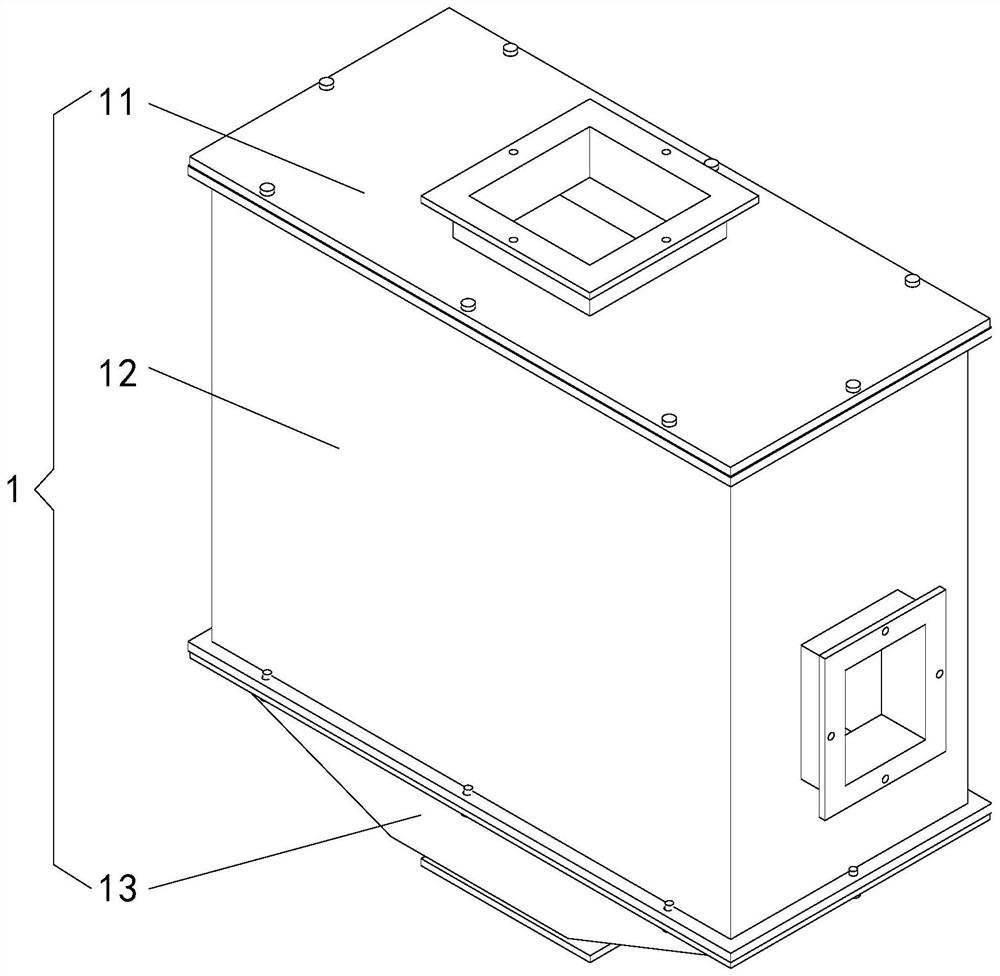

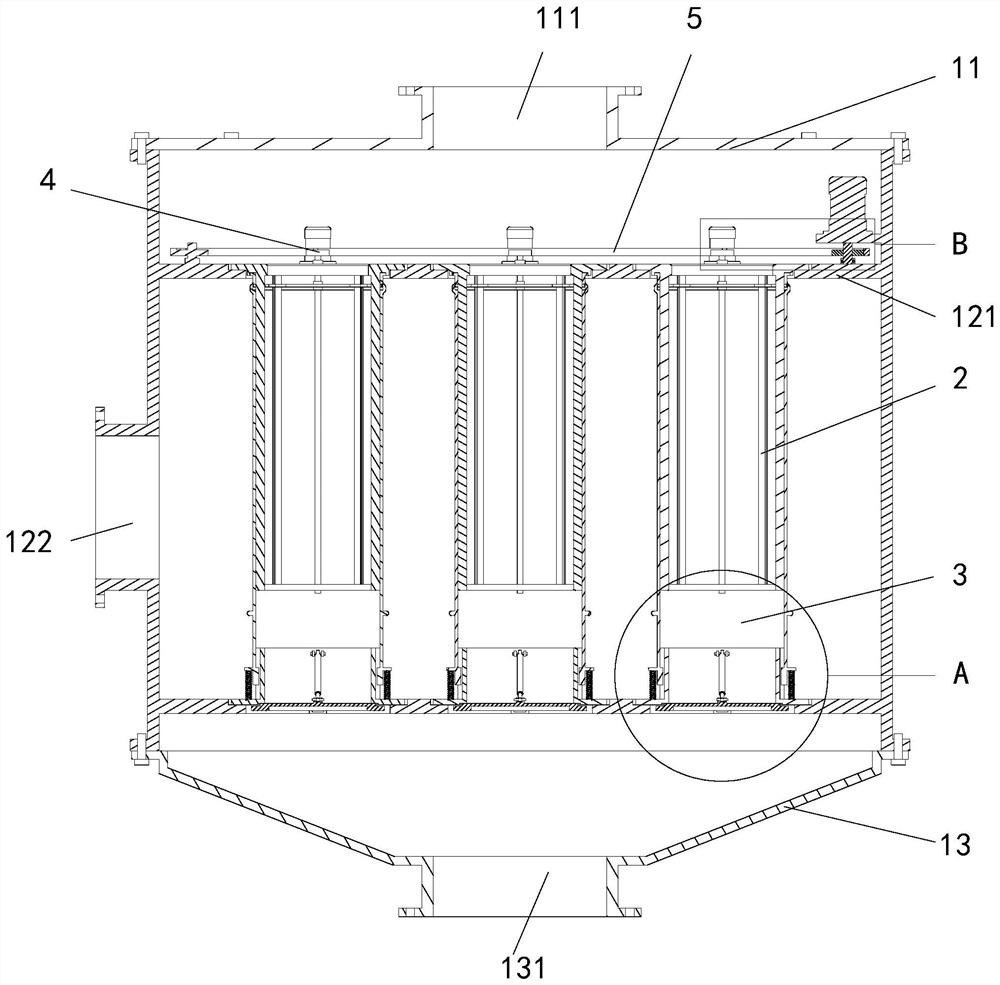

[0041] See attached Figure 1-12 As shown, an industrial bag filter includes a housing 1, three keel frame components 2, three dust bags 3, three bag-tying mechanisms 4 and a dust scraping ring drive mechanism 5, and the housing 1 includes a rectangular plate-shaped The upper sealing plate 11, the cube-shaped middle casing 12 and the dust discharge chamber 13 in the shape of an inverted square platform, the upper sealing plate 11 is fixed on the top of the middle casing 12 by bolts (in principle, the sealing of the connection should be ensured) , the dust disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com