Method for producing Luneberg lens without using adhesive

A technology of Lunberg lens and production method, which is applied to electrical components, antennas and other directions, can solve the problems of the influence of Lunberg lens performance indicators, etc., and achieve the effects of easy control of lens characteristics, excellent lens performance indicators, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

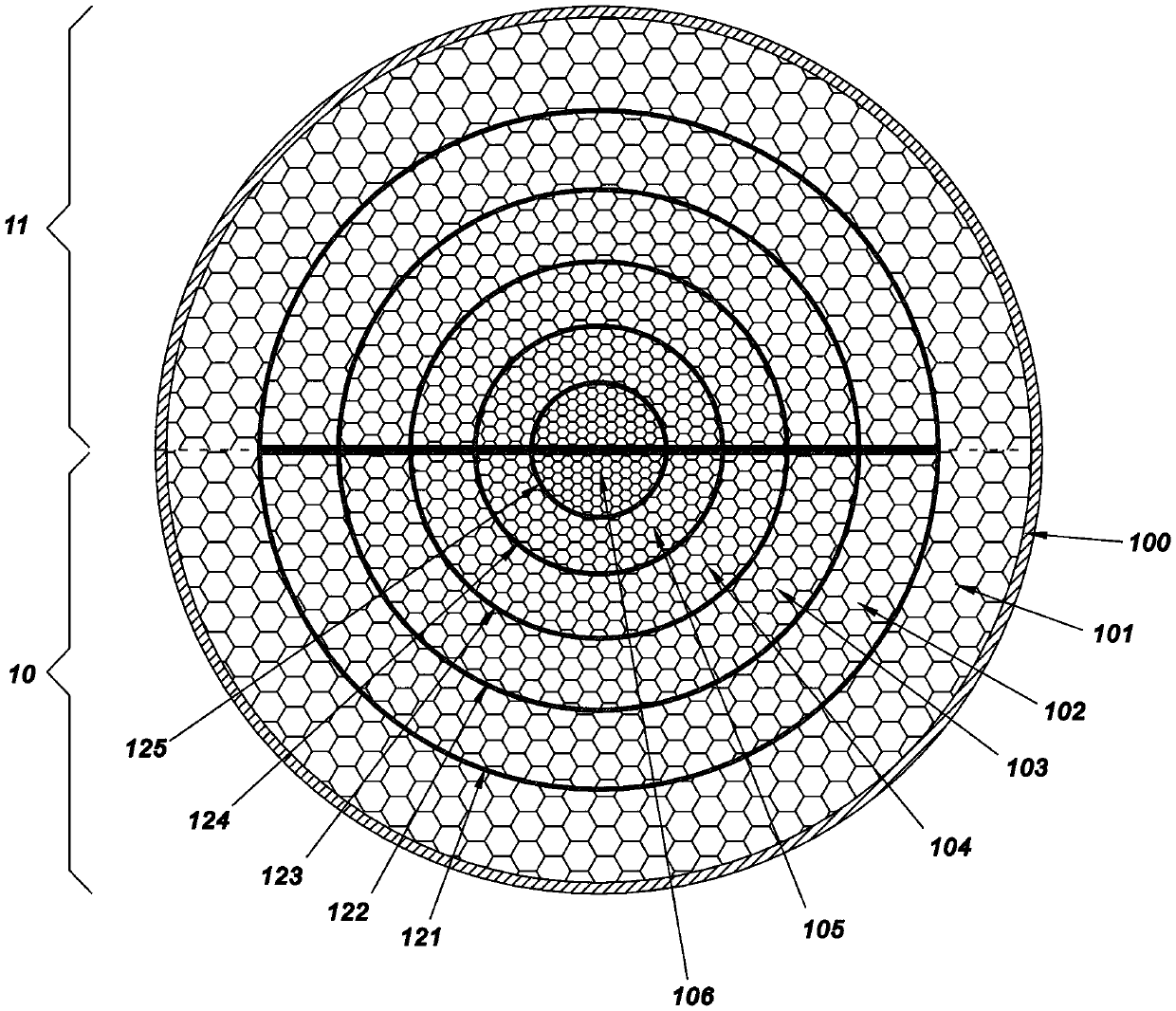

[0056] In this embodiment, the production of a spherical Lunberg lens with a mold core inside having 5 dielectric layers is taken as an example. like figure 1 As shown, such a Luneburg lens consists of two half Luneburg lenses 10 , 11 . The half-side Lunberg lens 10 comprises a hemispherical shell 100, a first dielectric layer 101, a second dielectric layer 102, a third dielectric layer 103, a fourth dielectric layer 104, a fifth dielectric layer 105 and a hemispherical core 106 from outside to inside; The Luneberg lens also includes a mold core 12 made of plastic.

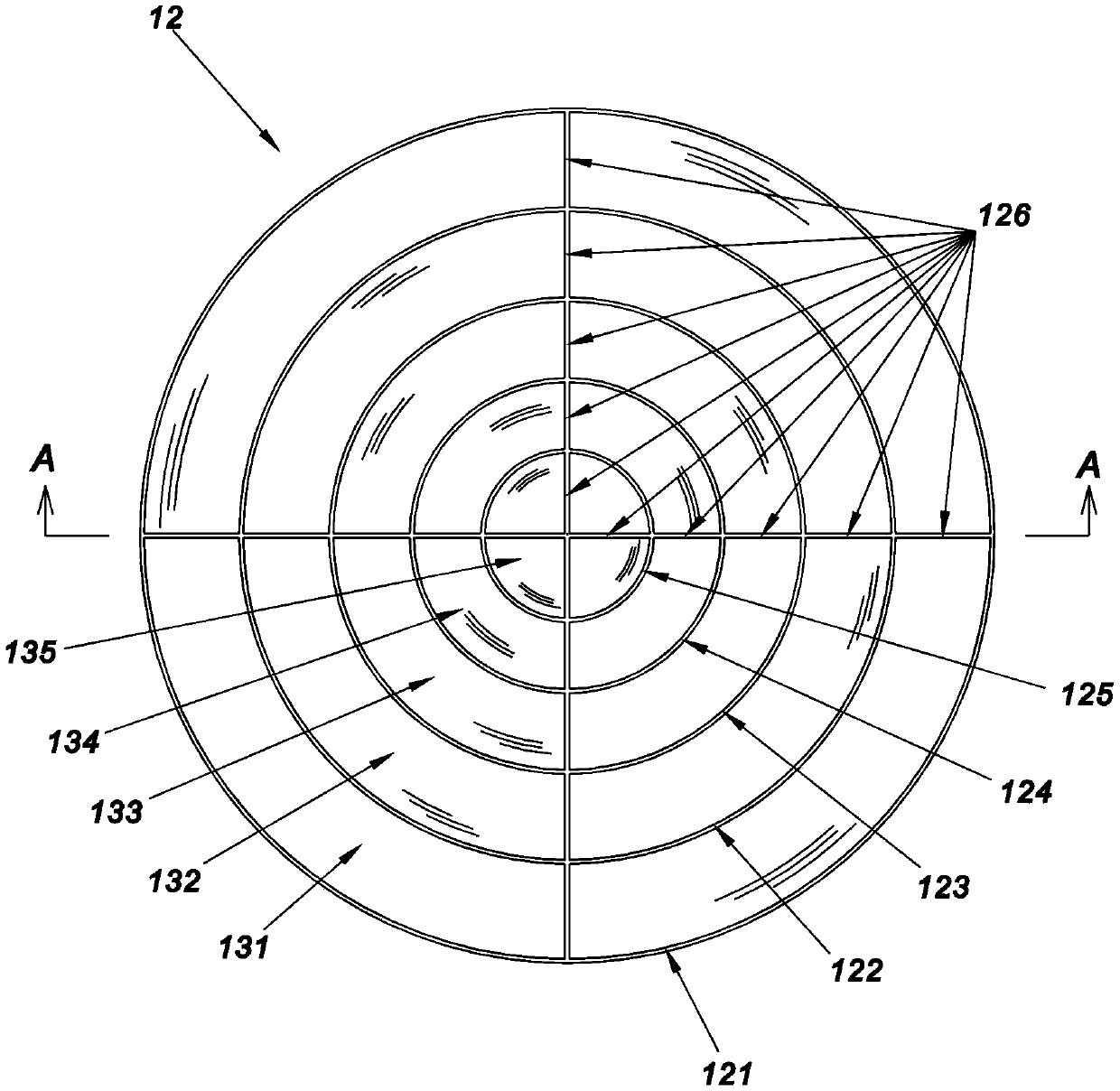

[0057] The structure of mold core 12 is: as figure 2 , image 3 As shown, it includes a first hemispherical shell part 121 , a second hemispherical shell part 122 , a third hemispherical shell part 123 , a fourth hemispherical shell part 124 , a fifth hemispherical shell part 125 and a connecting rib 126 . The first hemispherical shell part 121, the second hemispherical shell part 122, the third hemispherical...

Embodiment 2

[0068] In this embodiment, the production of a spherical Luneberg lens without a mold core with 5 dielectric layers is taken as an example. like Image 6 As shown, such a Luneburg lens consists of two half Luneburg lenses 50 , 51 . The half Lunberg lens 50 includes a hemispherical shell 500 , a first dielectric layer 501 , a second dielectric layer 502 , a third dielectric layer 503 , a fourth dielectric layer 504 , a fifth dielectric layer 505 and a hemispherical core 506 from outside to inside.

[0069] This embodiment also needs to use a mold core 52, and this mold core 52 can be made of plastics, also can be made of metal. like Figure 7 , Figure 8 As shown, the mold core 52 includes a first hemispherical shell part 521 , a second hemispherical shell part 522 , a third hemispherical shell part 523 , a fourth hemispherical shell part 524 , a fifth hemispherical shell part 525 and a rotating shaft 526 . The first hemispherical shell 521, the second hemispherical shell 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com