Thermoelectric refrigeration and film moisture permeability combined temperature and humidity control system

A technology of temperature and humidity control and thermoelectric refrigeration, which is applied in the direction of control/regulation system, non-electric variable control, and simultaneous control of multiple variables, etc., can solve the problem of inability to take into account the temperature, achieve good energy saving effect, ensure accuracy and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

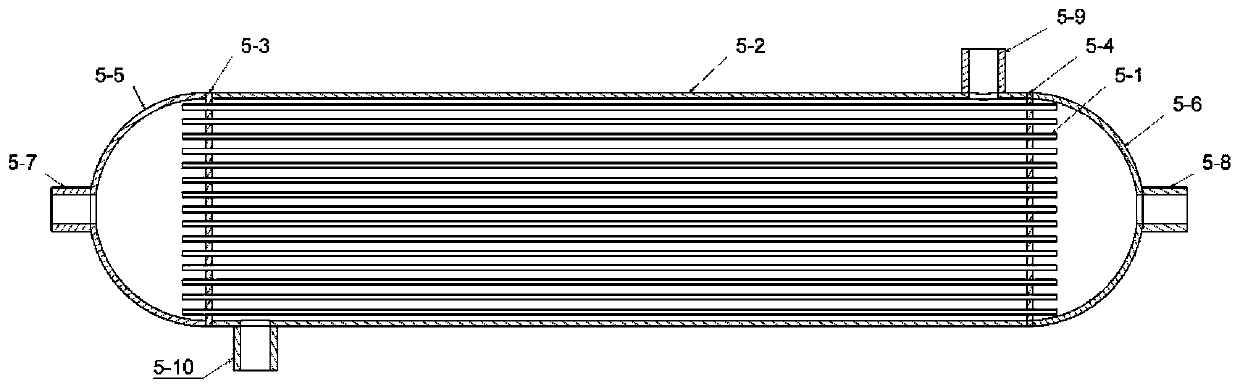

Image

Examples

Embodiment Construction

[0021] In view of the above-mentioned problems in the prior art, the present invention proposes to combine thermoelectric refrigeration with membrane moisture permeability technology, and switch the power supply direction of the thermoelectric module according to the requirement of temperature control to realize the heating or cooling function, and based on the cooling at one end of the thermoelectric module, the other The characteristic of heating at one end, while using the cooling / heating load at one end of the thermoelectric module for temperature control, makes full use of the heating / cooling load at the other end to create a mass transfer potential difference for the membrane module made of moisture-permeable membrane, driving water The steam conducts mass transfer across the membrane to achieve the purpose of humidification or dehumidification to achieve humidity control. This non-contact humidity control method can effectively avoid the problem of droplet entrainment an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com