Radio frequency thimble for production test and radio frequency test system

A production test, radio frequency technology, applied in the direction of continuity test, measurement electricity, measurement device, etc., can solve the problem of difficult to detect the deviation of radio frequency thimble, achieve low cost, good compatibility between color recognition sensor and radio frequency, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

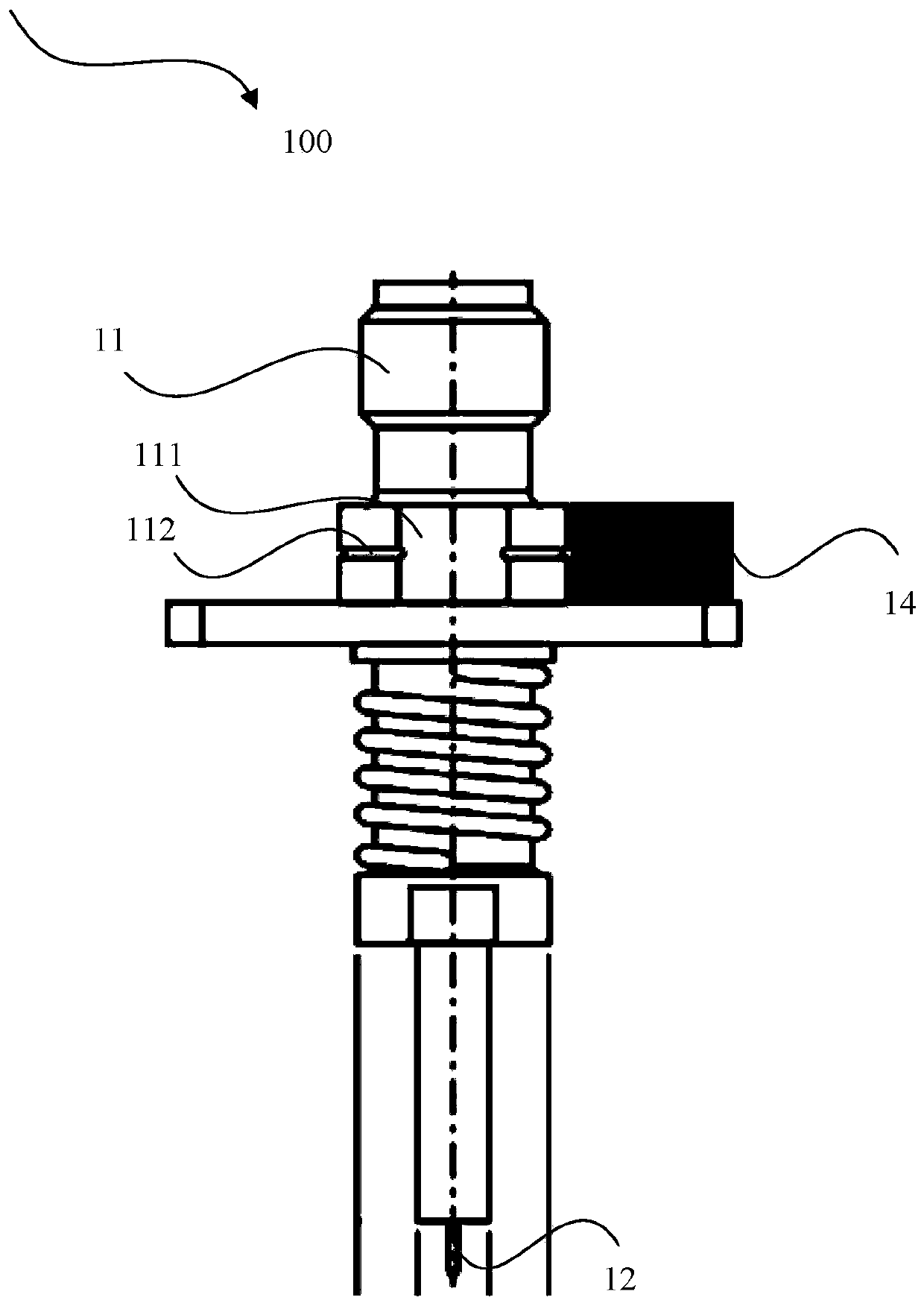

[0031] figure 1 A schematic diagram of the overall structure of the RF thimble for production testing provided by the embodiment of the present invention,

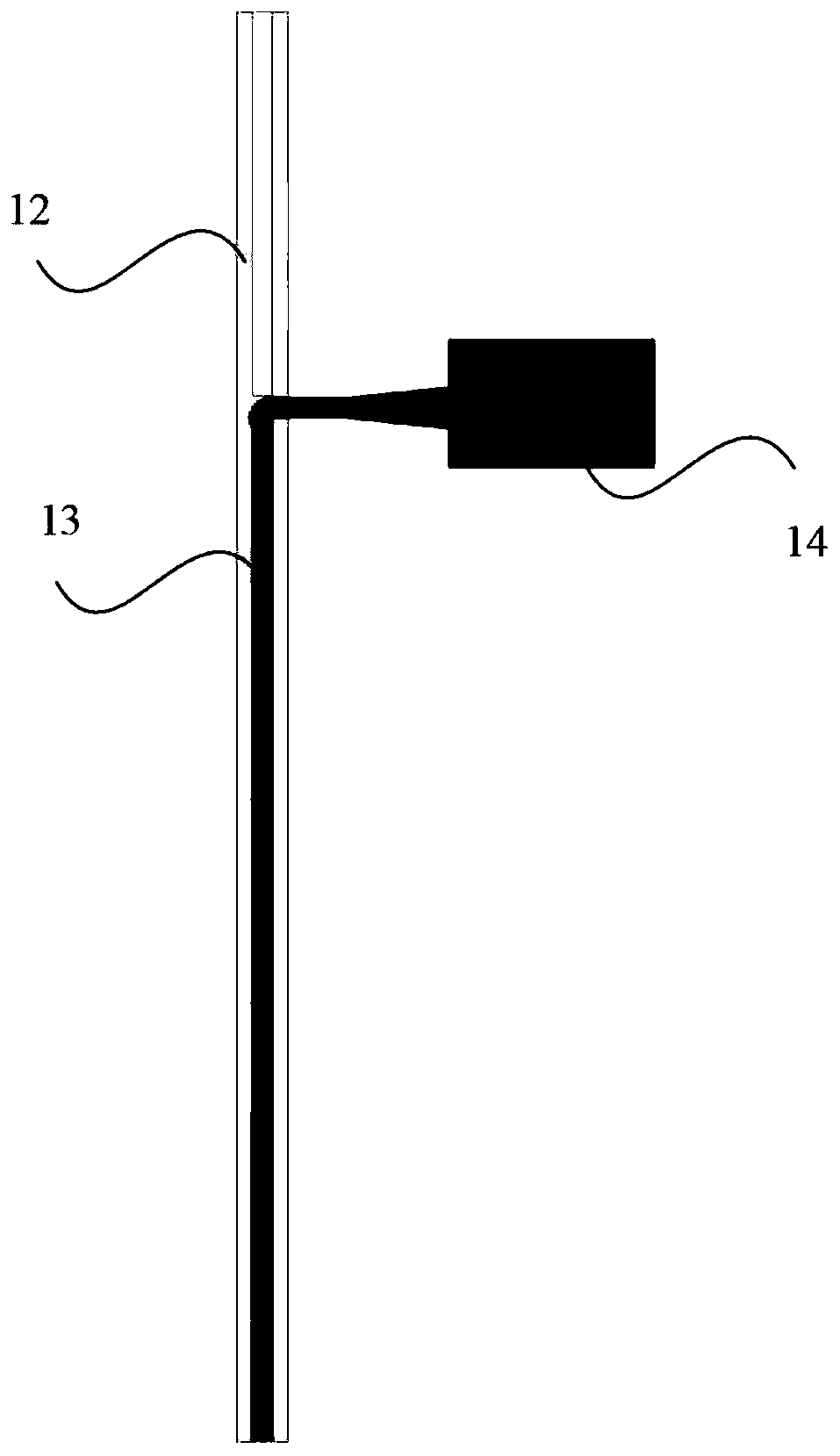

[0032] figure 2 For the connection diagram of the probe, the light guide and the color recognition sensor provided by the embodiment of the present invention, refer to figure 1 and figure 2 As shown, the embodiment of the present invention provides a radio frequency thimble 100 for production testing, which is used for mating connection with the test socket 200 .

[0033] Wherein, during the production test, it is necessary to coaxially set the RF thimble 100 and the test socket 200 through the RF fixture, and press down the RF thimble 100 to make contact with the coaxial connector test socket 200 to test the RF signal.

[0034] During the production test process, there are many reasons for the poor RF signal test, which may be the design of the RF fixture, the electrical performance failure of the main board, or the ...

Embodiment 2

[0058] Embodiment 2 of the present invention provides a radio frequency test system, including a test socket 200 and the radio frequency thimble 100 for production test provided in the above embodiment.

[0059] Wherein, during the production test, it is necessary to coaxially set the RF thimble 100 and the test socket 200 through the RF fixture, and press down the RF thimble 100 to make contact with the coaxial connector test socket 200 to test the RF signal.

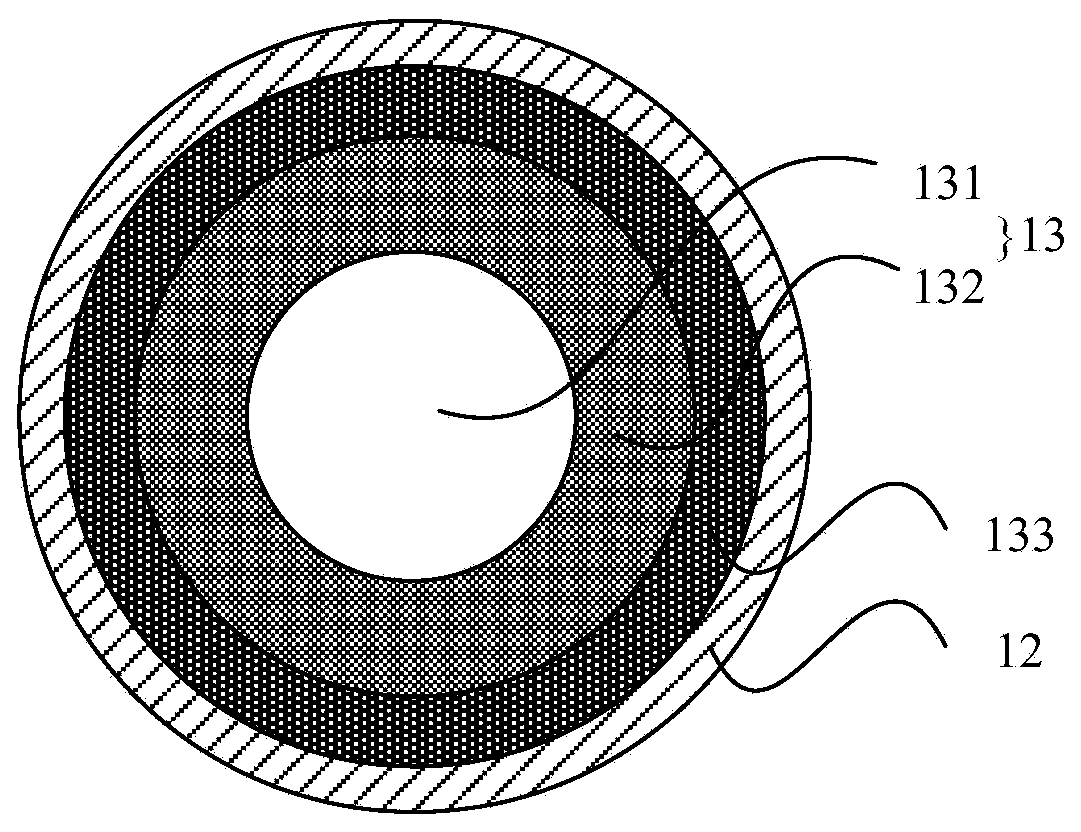

[0060] Specifically, the radio frequency thimble 100 includes: a housing 11, a probe 12, a light-conducting member 13, and a color recognition sensor 14; 13 is installed in the accommodating hole, the first end of the light-conducting member 13 is exposed at the end of the probe 12, the second end of the light-conducting member 13 is connected with the color recognition sensor 14, and the light-conducting member 13 is used to connect the end of the probe 12 The reflected light from the reflective surface close to the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com