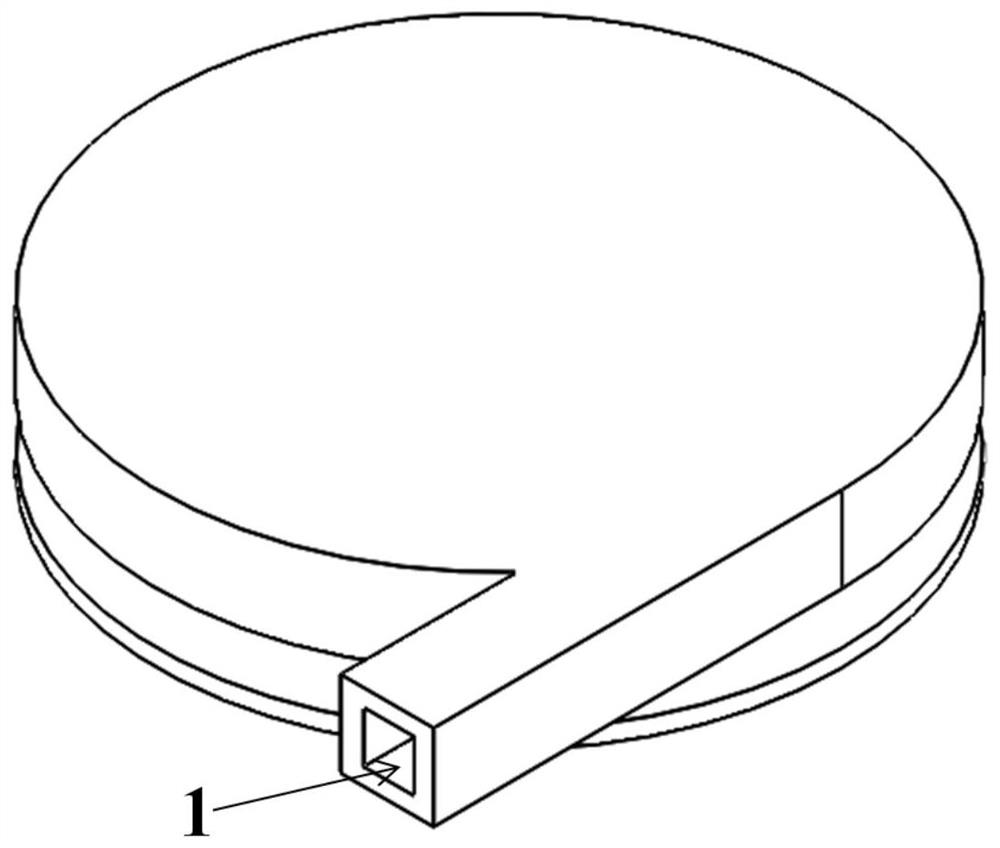

A Small Disc Premixed Burner with Efficient Preheating and Flashback Prevention

A premixed combustion and anti-backfire technology, applied in burners, gas fuel burners, combustion types, etc., can solve the problems of inability to effectively anchor the flame position, large weight and volume, and time to supplement energy consumption, etc. Flame flammable range, uniform temperature distribution, strong super-enthalpy combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0045] In this embodiment, methane / air mixture is used as fuel. The fuel preheating channel has a spiral structure, its width and height are 3mm, its outlet diameter is 2mm, the thickness of the vertical wall is 2mm, and the thickness of the upper and lower walls is 1mm; the inner diameter of the fuel channel in the center of the disc is 2mm, and the height is 3mm; the annular protrusion The inner diameter is 2mm, the outer diameter is 6mm, and the height is 2mm; the inlet diameter of the annular combustion chamber is 2mm, the outer diameter is 40mm, and the spacing is 3mm; the thickness of the lower wall of the annular combustion chamber is 1mm. The surface of the annular combustion chamber is not coated with catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com