A rolling mill guide lubricating grease heating device

A technology of heating device and lubricating grease, which is applied in the direction of engine lubrication, guiding/positioning/alignment device, lubricating parts, etc., which can solve the problems of increased hardness of lubricating grease, increased failure time, rolling waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

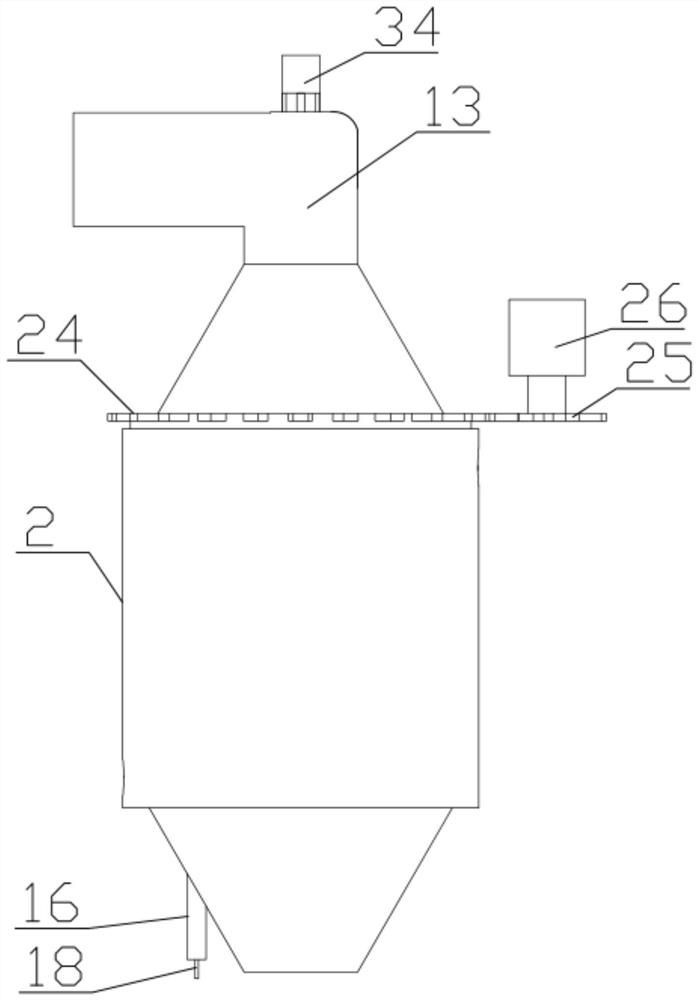

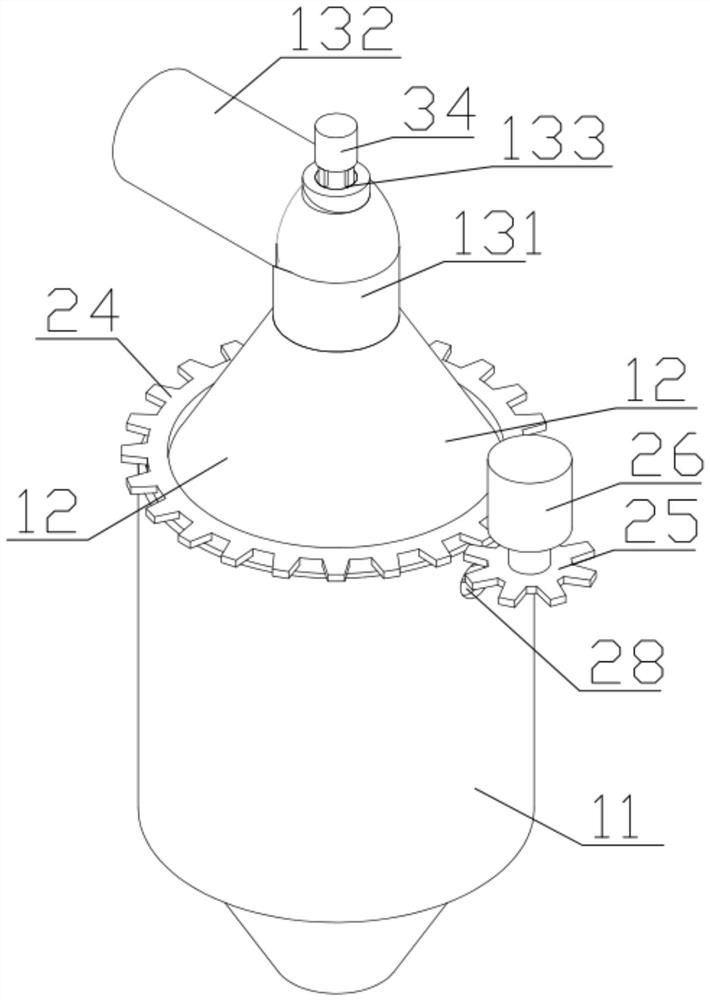

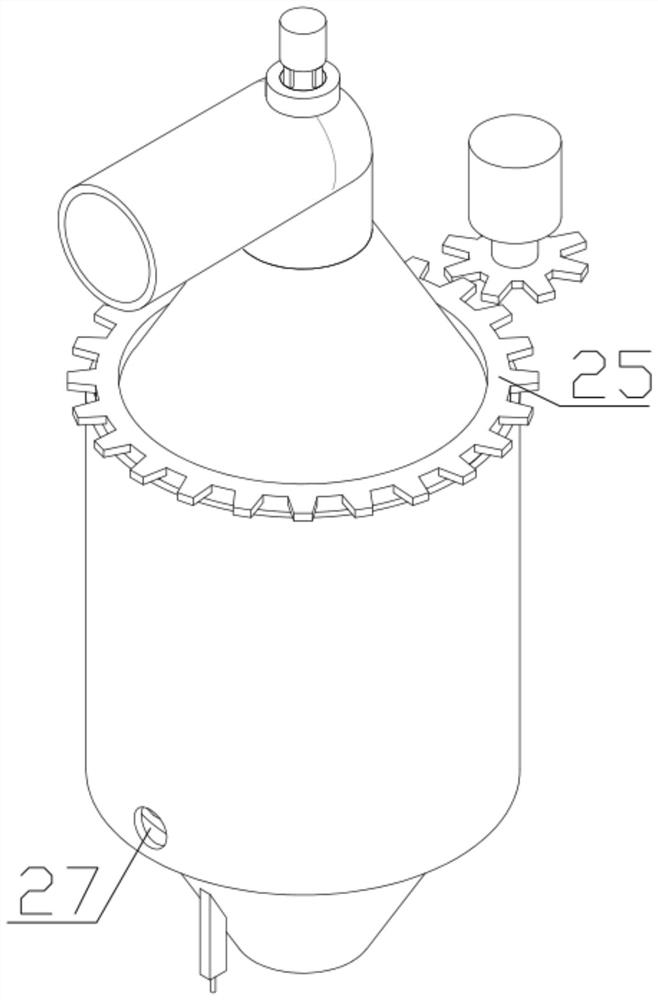

[0043]A rolling mill guide lubricating grease heating device, comprising a gas pipeline 1 and a grease pipeline 2 sleeved on the annular surface of the gas pipeline 1; the gas pipeline 1 includes an annular pipe 11 connected to the The tapered pipe 12 at the top and the bottom of one 11, the air intake pipe 13 connecting the tapered pipe 12 at the top, the filter plate 14 arranged inside the annular pipe 11; The annular pipe two 21 outside the annular surface of 11, the fat transfusion chamber 22 enclosed between the annular pipe one 11 and the annular pipe two 21, the arc-shaped scraper 23 arranged in the fat transfusion chamber 22, the arc scraper 23 arranged on the annular pipe two 21 top and connected to the gear plate 24 at the top of the arc-shaped scraper 23, the gear plate 25 adapted to the gear plate 24, the rotating motor one 26 driving the gear plate 25, and the bottom of the annular surface of the ring pipe two 21 Grease inlet hole 27, the grease outlet hole 28 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com