A U-shaped gate valve

A U-shaped, gate valve technology, applied in valve details, valve devices, sliding valves, etc., can solve problems that are difficult to realize, and achieve the effects of avoiding excessive pressure, reducing process difficulty, and good work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

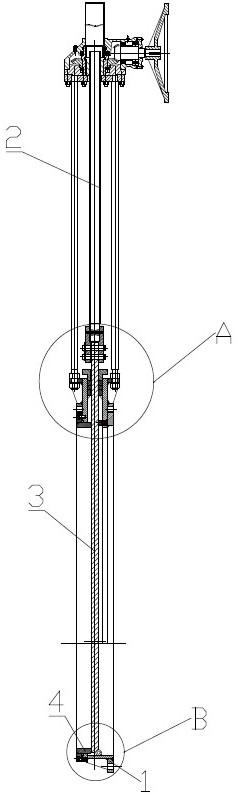

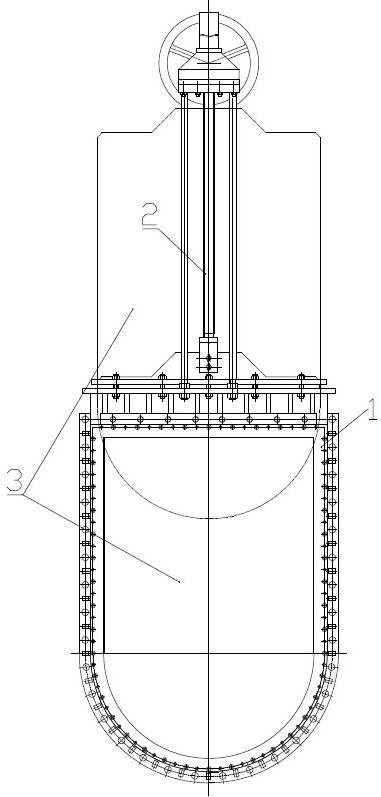

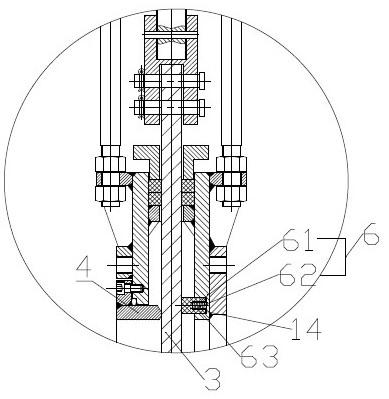

[0028] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0029] As shown in the figure, a U-shaped gate valve includes a valve body 1, a valve stem 2, a valve plate 3 and a valve seat 4, the valve body 1 and the valve seat 4 clamp the valve plate 3 together, and the valve The plate 3 is U-shaped, and an elastic member is provided between the valve plate 3 and the valve body 1 to provide the thrust required for the sealing fit between the valve plate 3 and the valve seat 4. The elastic member includes several U-shaped arrangements installed on the The first elastic member 5 on the valve body 1, the first elastic member 5 is tubular and has a gap 51 along the length direction, and the valve body and the valve seat are connected by a movable adjustable connection. The first elastic part adopts a pipe with a notch, and when it is squeezed by an external force, it will deform and generate an external elastic force, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com