Diesel injector and method of manufacturing diesel injector

A technology of injectors and fuel injectors, applied in the direction of manufacturing tools, fuel injection devices, special fuel injection devices, etc., can solve problems such as engine performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

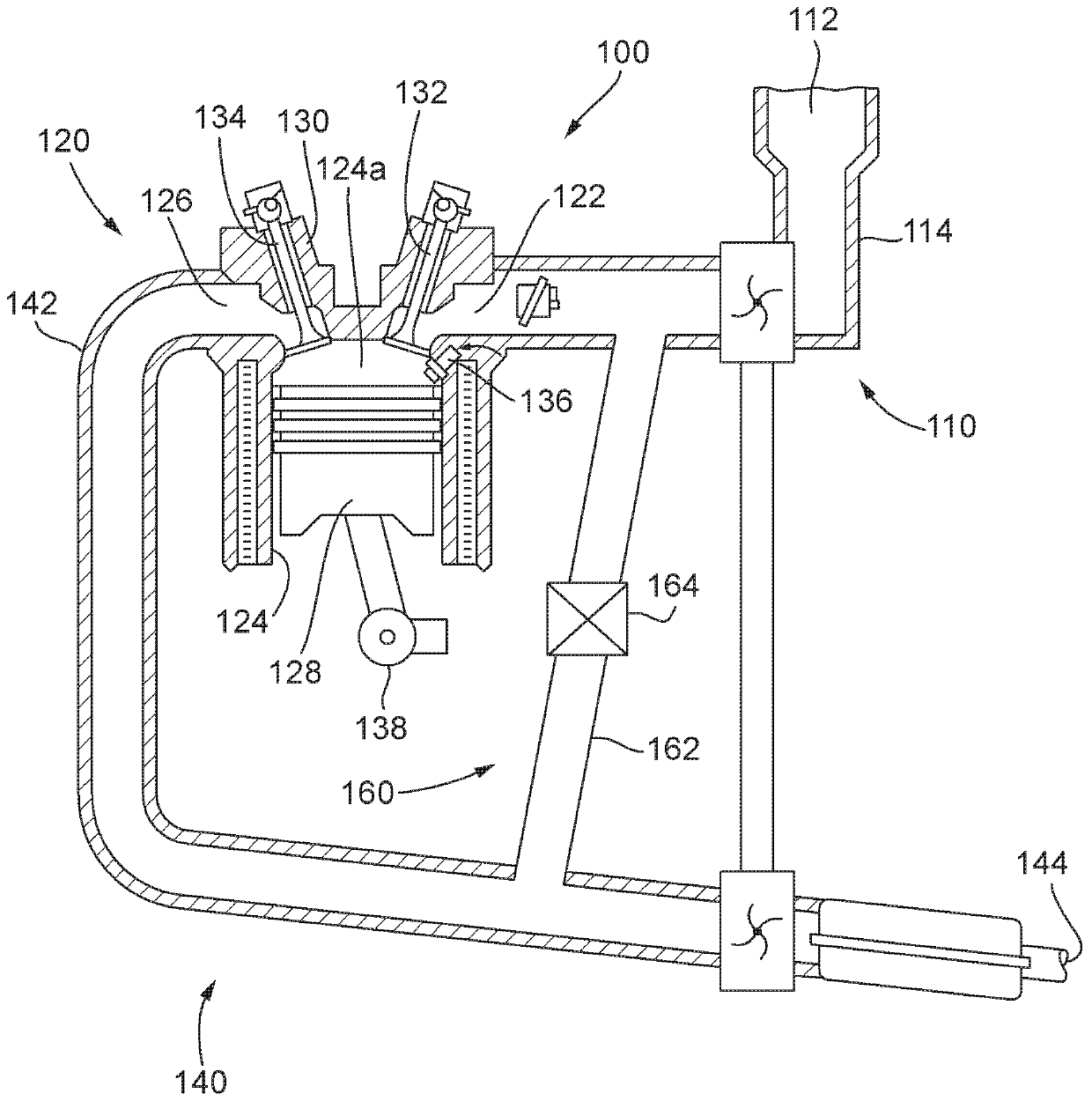

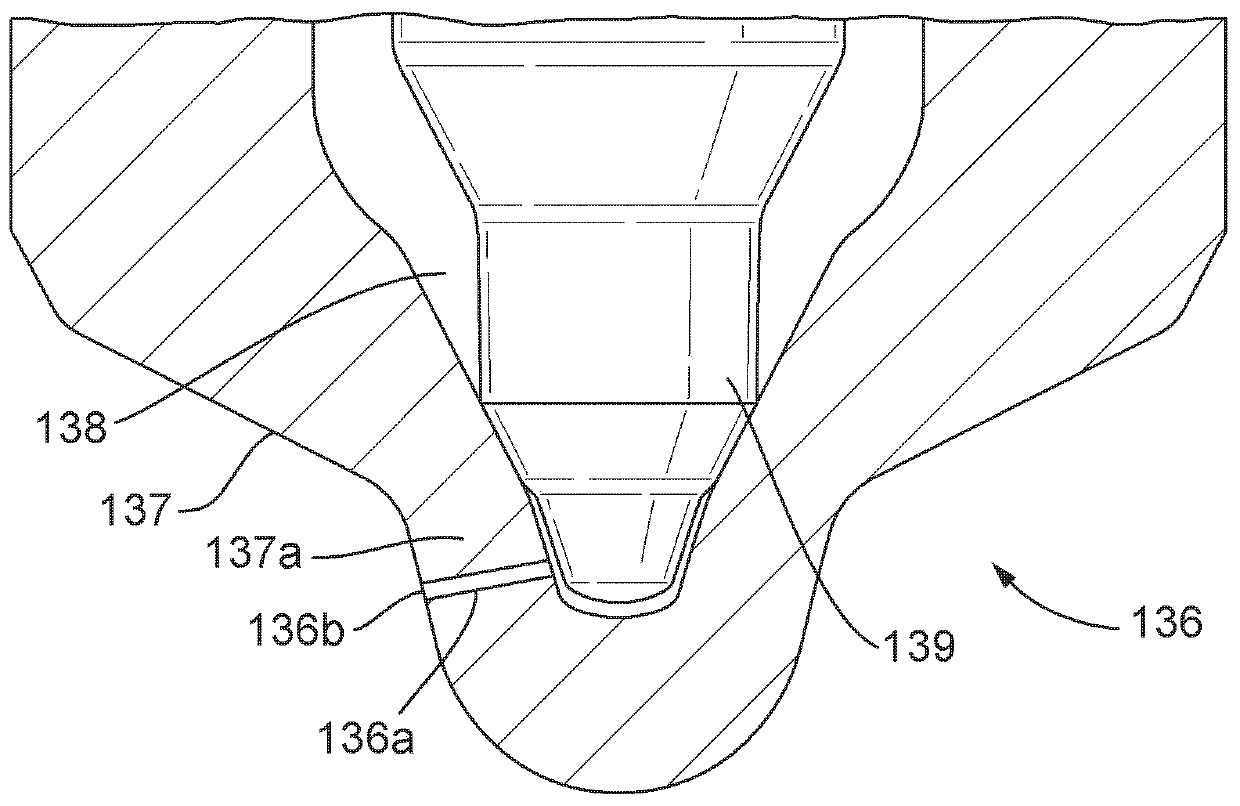

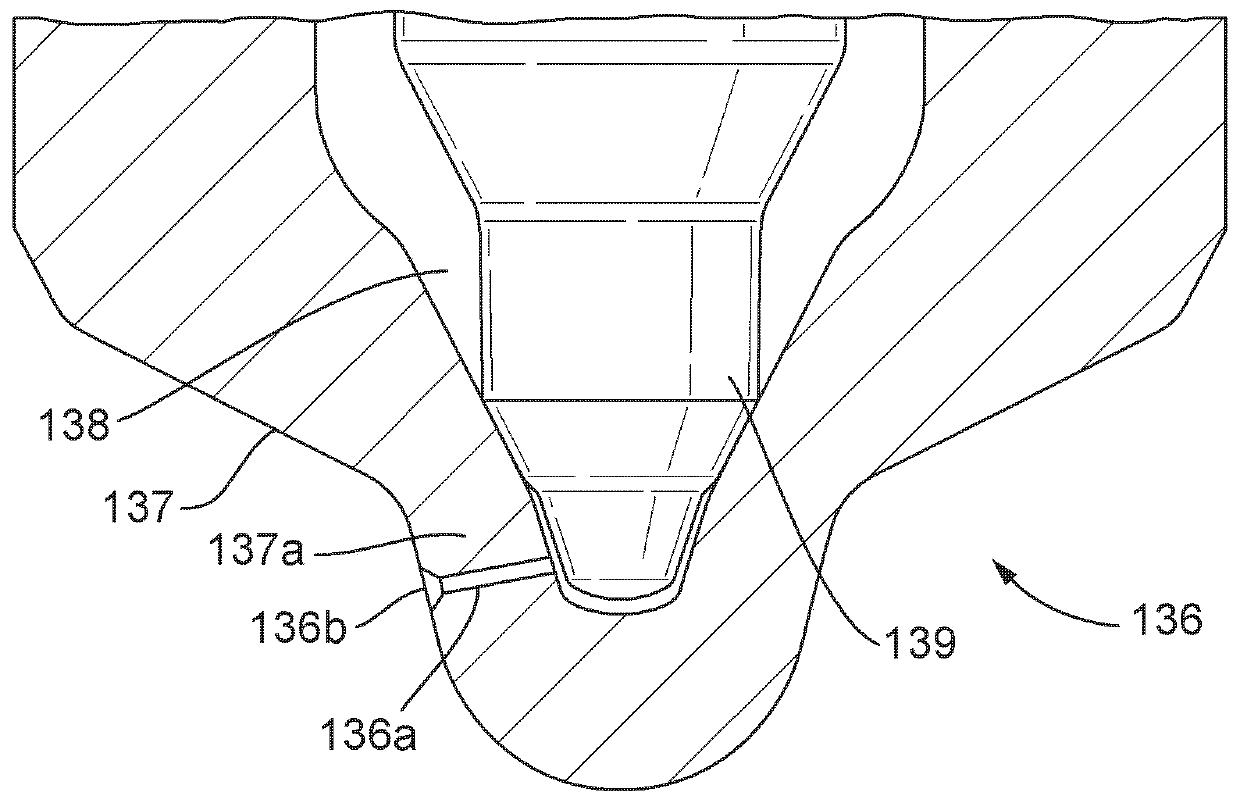

[0053] refer to Figure 3a with Figure 3b According to an arrangement of the present disclosure, a fuel injector (eg, a diesel fuel injector) 300 includes an injector body 310 defining an interior space 320 of the fuel injector wherein fuel is maintained at an injection pressure prior to being injected. The fuel injector 300 also includes a needle 330 movable within the interior space to control the operation of the injector 300 .

[0054] The injector body 310 includes a first thickness of material 312 . The first thickness of material 312 extends outwardly (eg, relative to the interior space 320 ), from an inner extent 312a of the first thickness of material to an outer extent 312b of the first thickness of material. Inner extent 312a defines an inner surface 310a of injector body 310 that at least partially defines interior volume 320 of fuel injector 300 .

[0055] The thickness of the first thickness material 312, eg, the dimension defined between the inner extent 312...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com