Modular high-rise building

A high-rise building and unitized technology, applied to building components, residential buildings, special structures, etc., can solve the problems of low corridor quality, thin-waisted planes that are unfavorable for earthquake resistance, and unsquare spaces, etc., to achieve improved convection and ventilation performance, Improve lighting and ventilation, improve the effect of corridor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

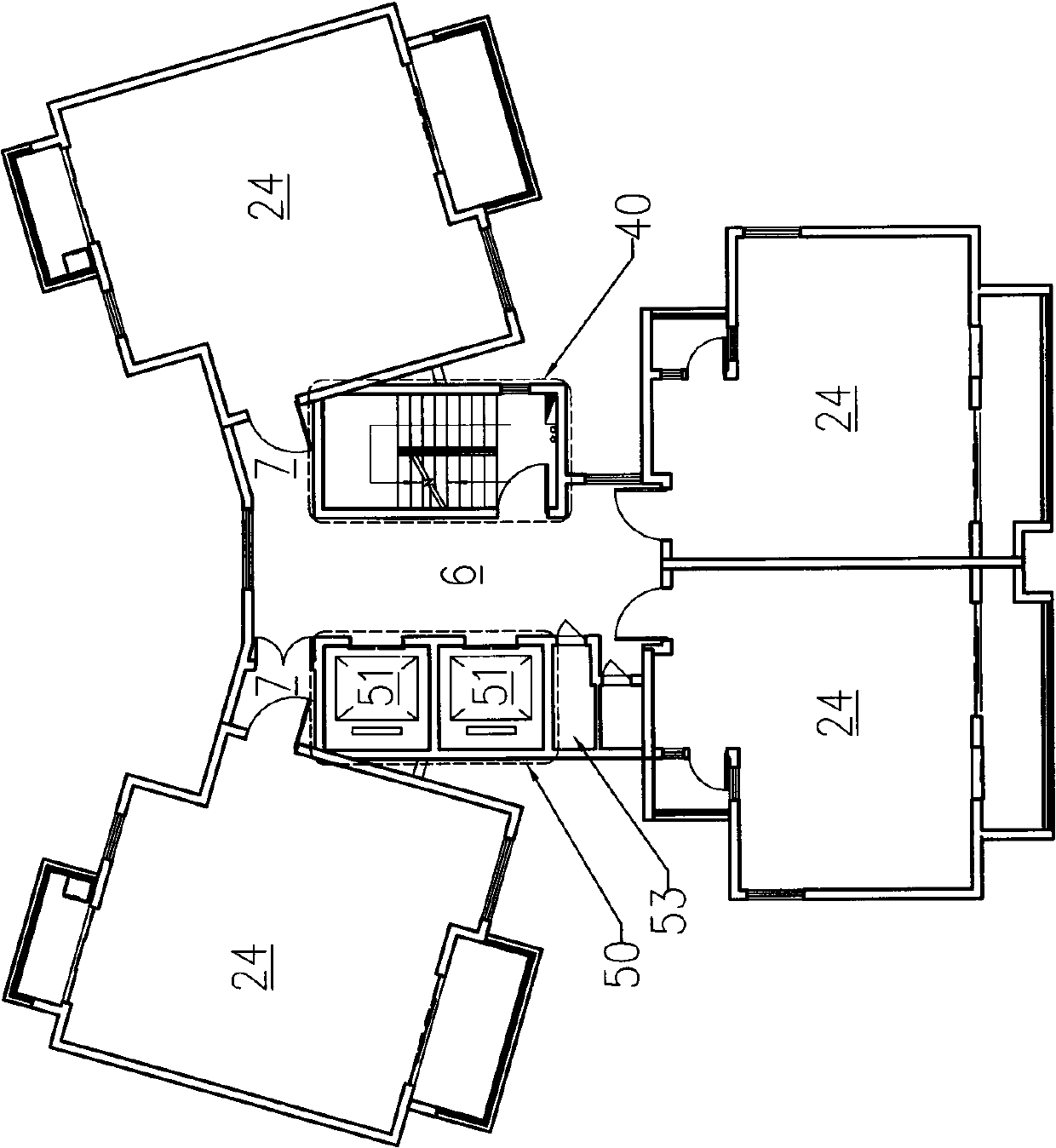

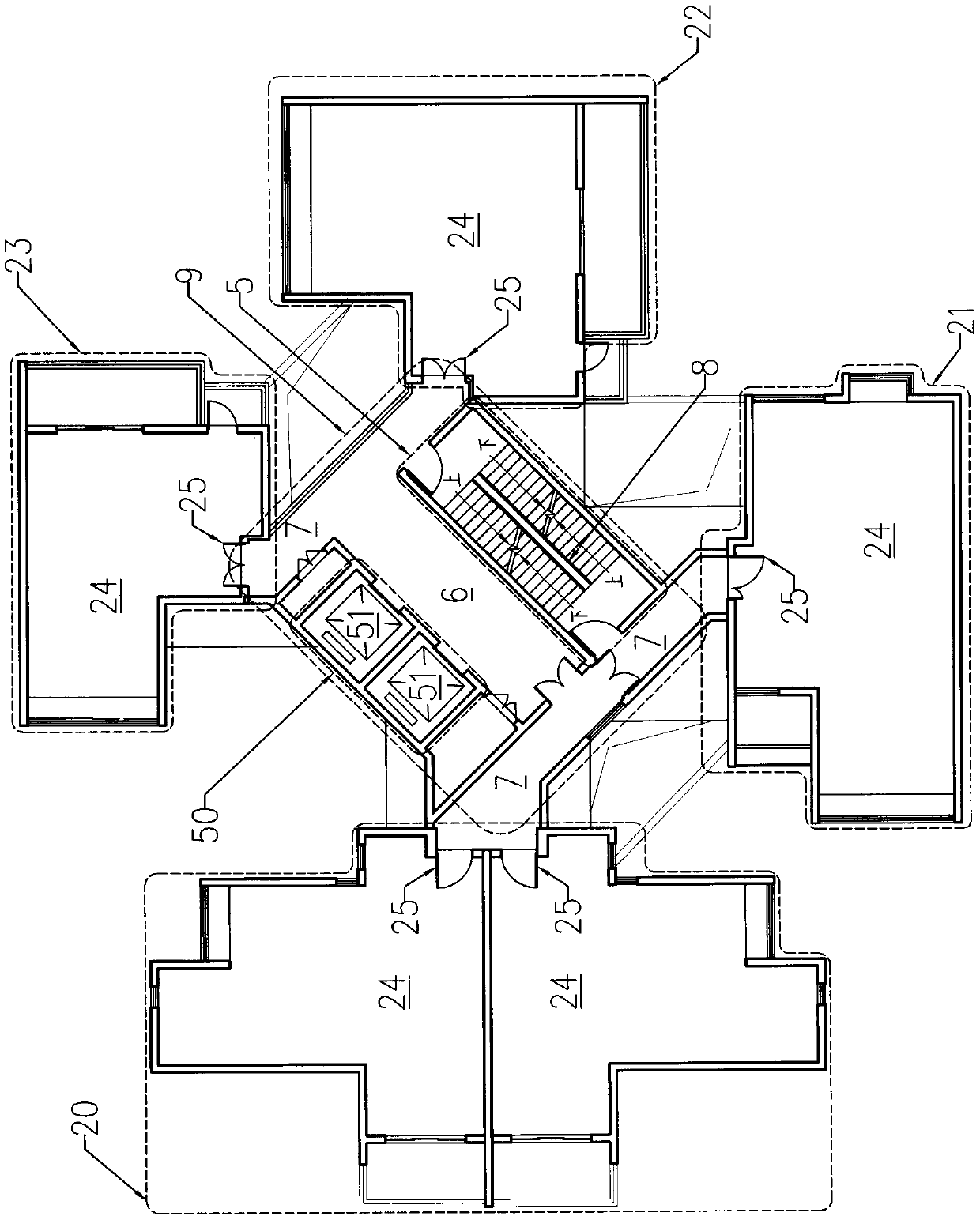

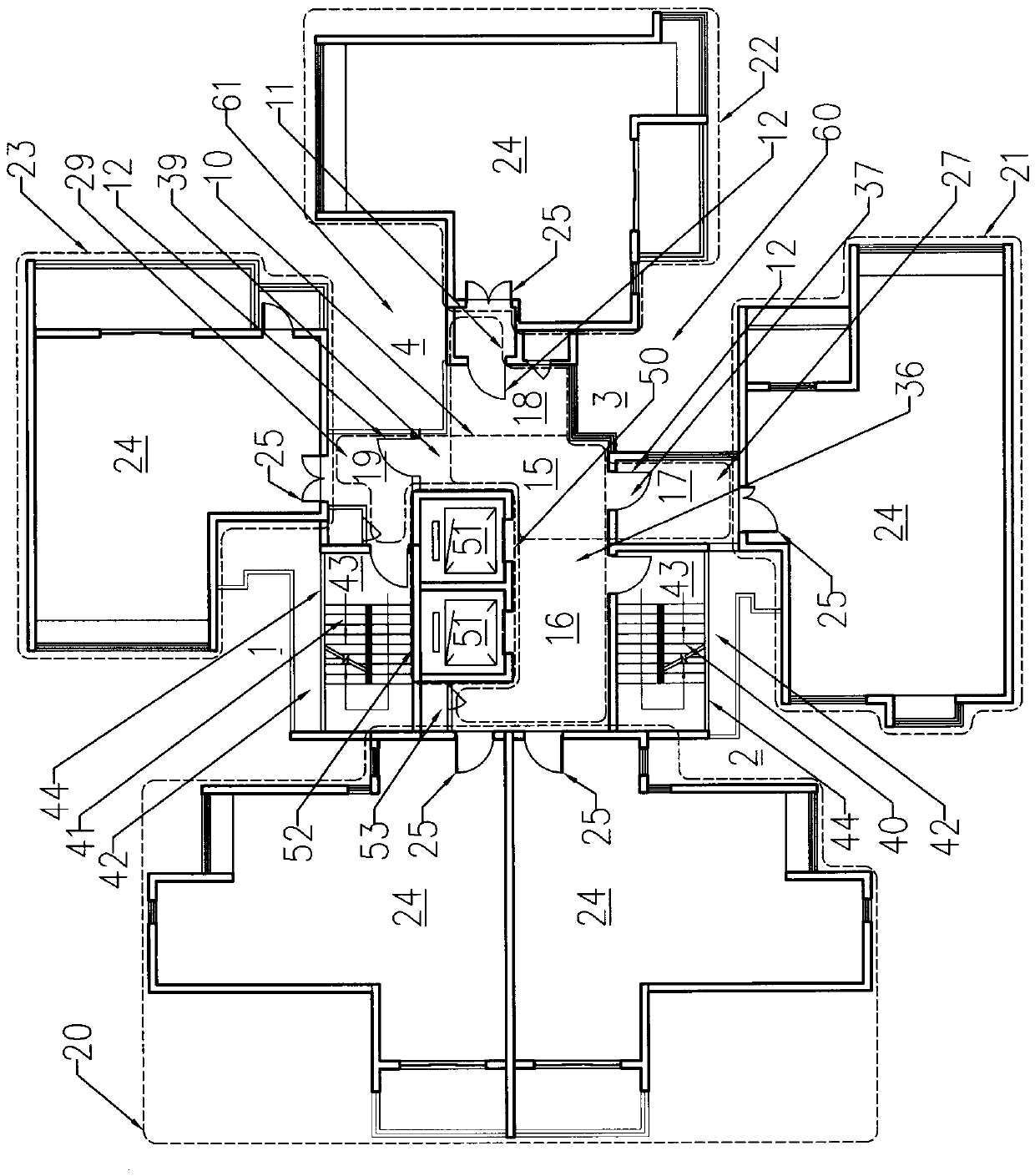

[0049] In order to explain how the invention works, the following terms are defined:

[0050] (1) Unit high-rise building: usually a building core tube is directly connected or connected to one or more units on each floor through a public corridor to form a unit high-rise building; usually a unit high-rise building can be independently formed into a high-rise building . Multiple units can also be spliced and combined to form a multi-unit high-rise building, and the multiple units of the multi-unit high-rise building can be disconnected, or only connected through the roof, or only connected through partial floors. The unit high-rise building referred to in this patent specifically refers to a high-rise building consisting of only one unit, or one of the units of a multi-unit high-rise building.

[0051] (2) "Ten" planar corridor: It is composed of two belt-shaped planar corridors, which cross each other. The intersection of the two strip-shaped corridors forms four internal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com