Construction method for pre-stress tubular pile containing deep boulders and pile foundation structure thereof

A technology of prestressed pipe piles and construction methods, which is applied in foundation structure engineering, foundation structure tests, sheet pile walls, etc., can solve the problems that the quality of pile foundation construction is difficult to be guaranteed, and piles cannot be formed, so as to achieve economic benefits and social benefits. Significant effect, guaranteed quality, improved bearing capacity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

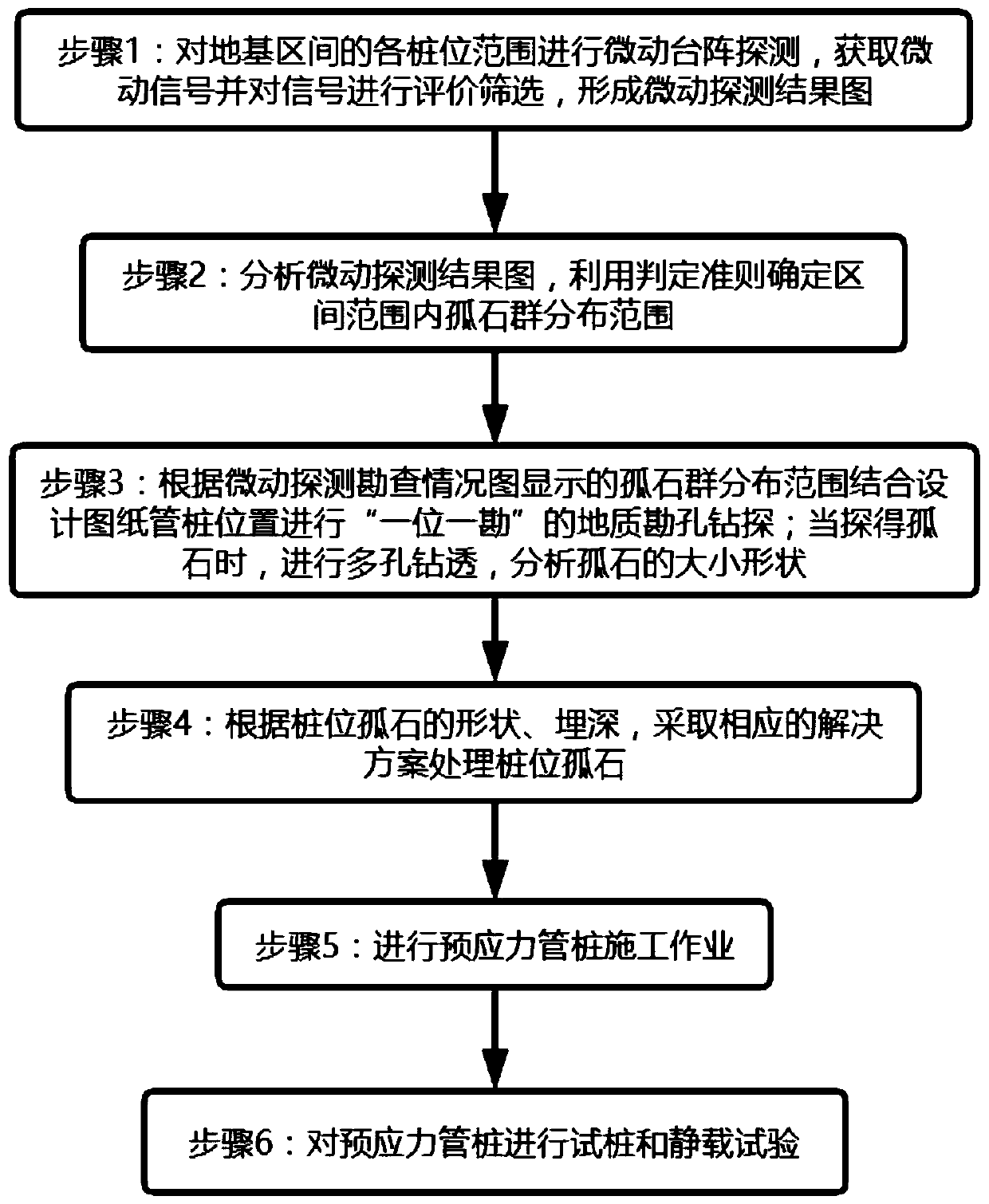

[0032] A kind of construction method of the prestressed pipe pile pile foundation structure that contains deep boulders in this embodiment, please refer to figure 1 , including the following steps,

[0033] Step 1: Perform micro-motion array detection on the range of each pile position in the foundation interval, obtain micro-motion signals, evaluate and screen the signals, and form a micro-motion detection result map;

[0034] Step 2: Analyze the micro-motion detection result map, and use the judgment criterion to determine the distribution range of boulder groups within the interval;

[0035] Step 3: According to the distribution range of the boulder group shown in the micro-motion detection and exploration situation map, combined with the position of the pipe pile on the design drawing, conduct "one-by-one survey" geological exploration drilling; when boulders are found, perform multi-hole drilling to analyze the boulders the size and shape of the stone;

[0036] Step 4: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com