A waste paper raw material beater

A technology for beating raw materials and waste paper, applied in the field of papermaking, can solve the problems of poor paper crushing effect, insufficient beating, and inability to control the feeding speed of waste paper raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

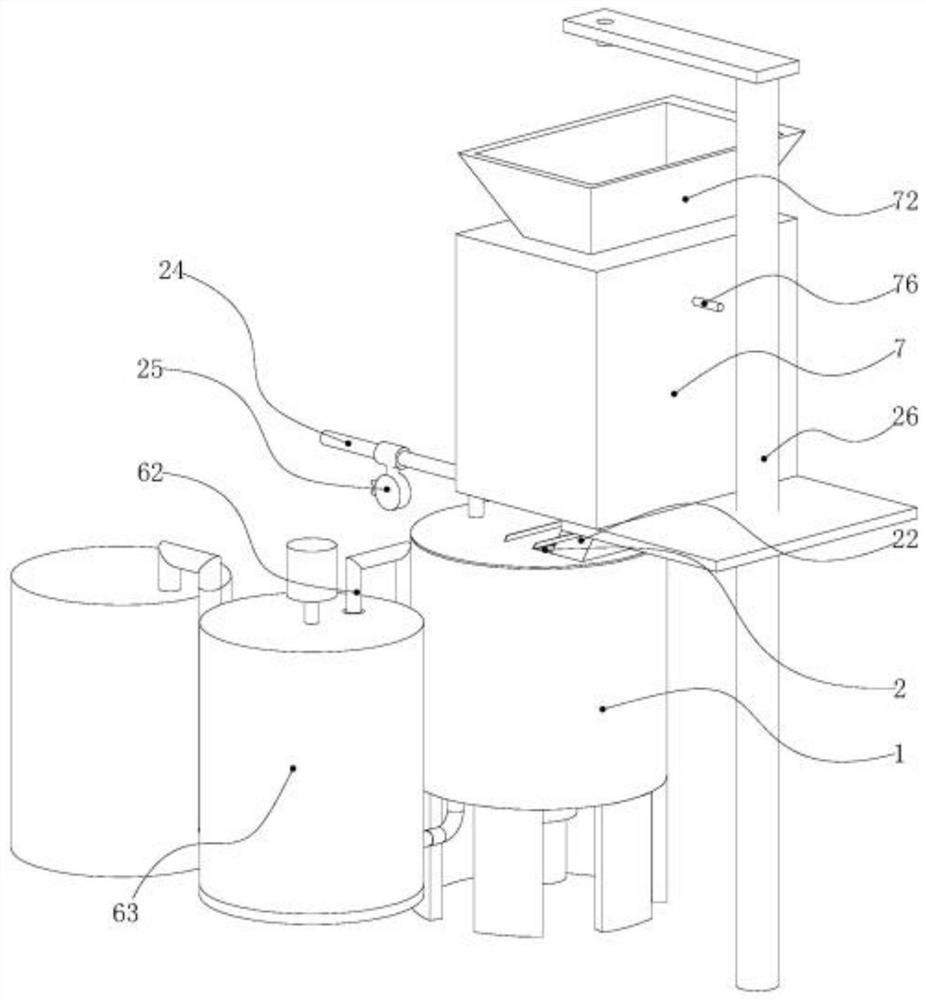

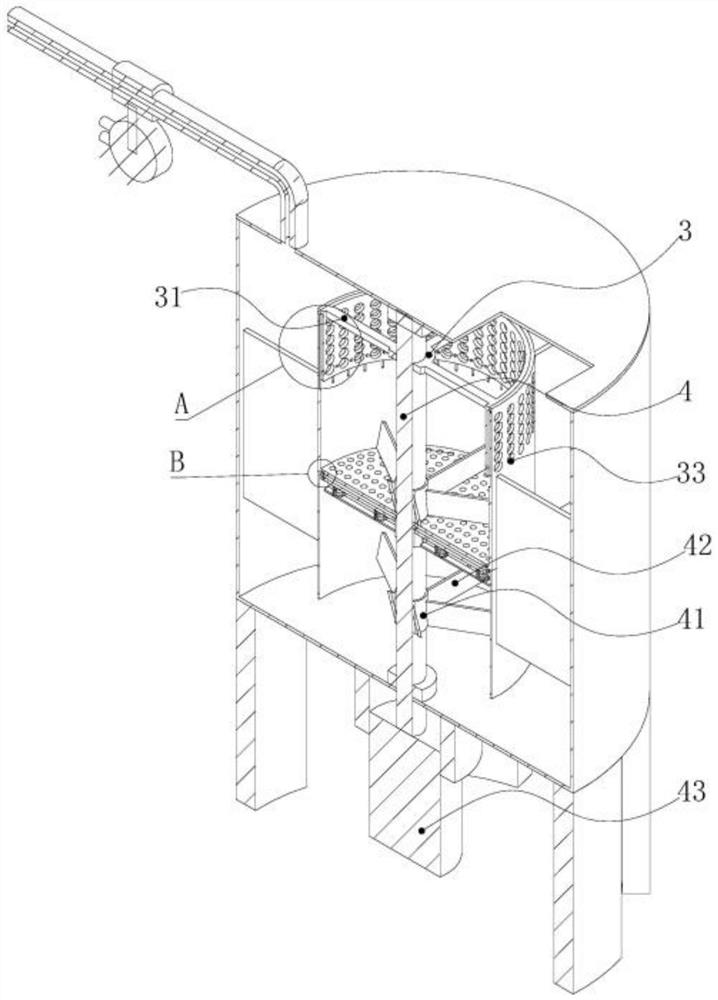

[0023] like Figure 1-10 As shown, a waste paper raw material beater includes a crushing device, a filter device, a beating cylinder 1, an inner cylinder, a beating mechanism and a drainage mechanism, and the crushing device includes a crushing box 7, a feeding port 71, a hopper 72, Plate 73, sliding groove 74, slide block 75, screw rod 76, crushing roller 77, crushing teeth 78, feed inlet 2, feeding pipe 22, water inlet pipe 24, flow meter 25 and fixed frame 26, described crushing box 7 is fixed On the fixed frame 26, the discharge port 71 is set on the top of the crushing box, the discharge hopper 72 is covered on the discharge port, the baffle plate 73 is symmetrically arranged on both sides of the discharge port, and one side of the baffle plate is hinged on the On the inner wall of the crushing box, the sliding groove 74 is provided on the lower surface of the baffle plate 73, and the slide block 75 can slide relative to the sliding groove, and the screw rod is screwed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com