Flow uniformizing piece, process chamber, atomic layer deposition equipment and deposition method

An atomic layer deposition and process chamber technology, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve problems affecting film thickness uniformity, composition and performance, particle contamination, pollution, etc. Effects of improved film thickness uniformity and process repeatability, improved particle levels, improved film quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

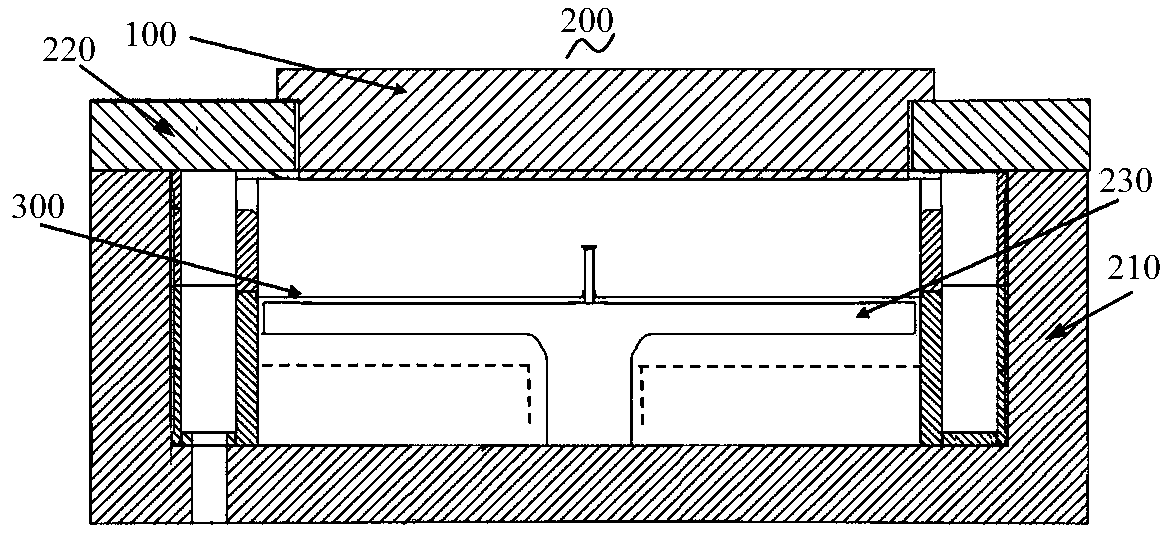

[0045] like figure 1 Shown is a schematic structural diagram of a process chamber of an atomic layer deposition equipment in the prior art. The process chamber 200 includes a chamber body 210, a top cover 220 covering the top of the chamber body 210, a flow uniform member 100 connected to the top cover 220 and communicating with the interior of the chamber body 210, and a The heating base 230 is used to support the silicon wafer 300 .

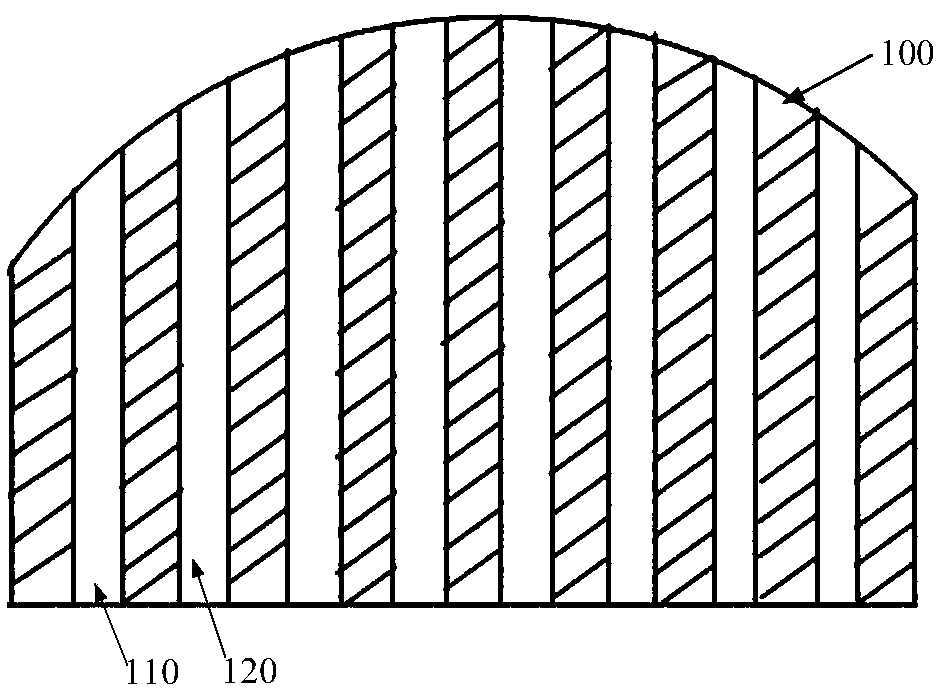

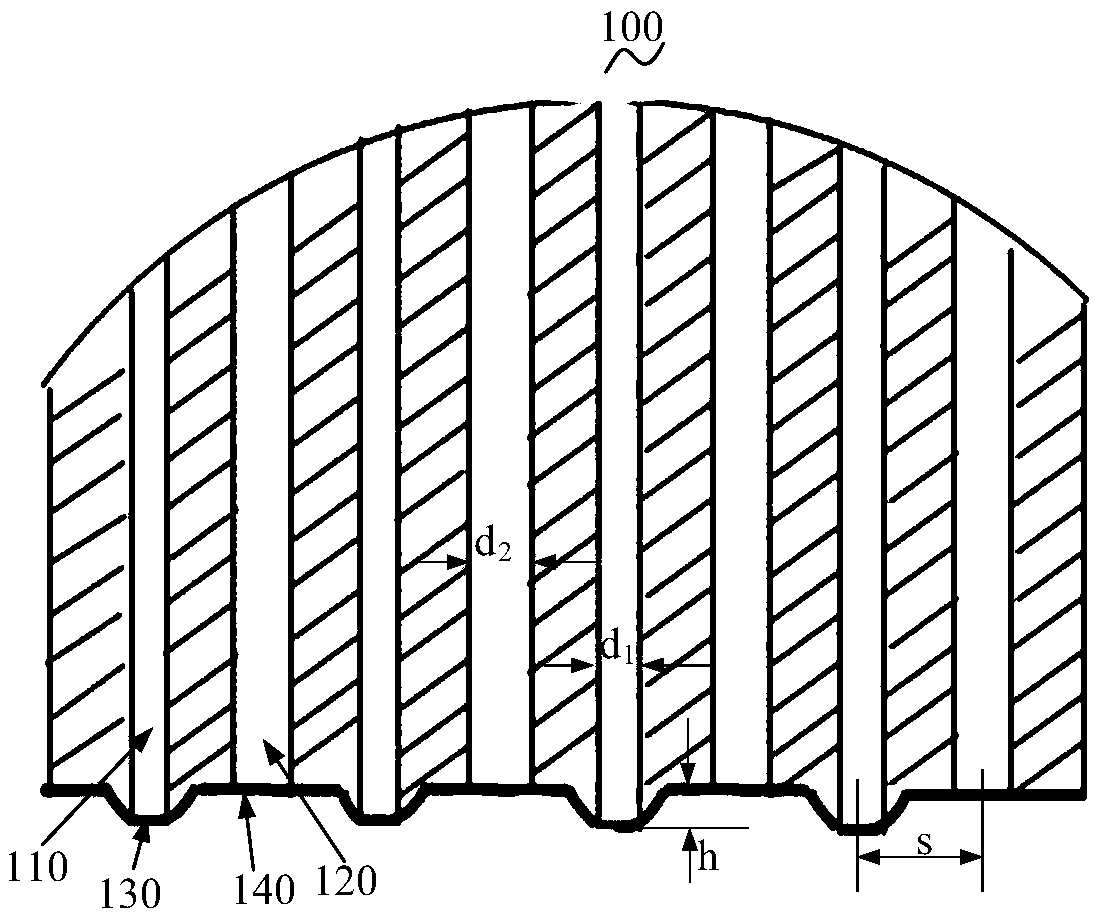

[0046] like figure 2 Shown is a schematic structural diagram of a flow equalizer in the prior art. The flow uniformity member 100 includes a plurality of first flow uniformity holes 110 and second flow uniformity holes 120 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com