Food preservation antibacterial container vacuumizing and nitrogen charging device

A technology of food preservation and packaging cans, which is applied in the direction of pressurized/gasification packaging, etc., can solve the problems of food safety that cannot meet people's needs, poor packaging technology, and short preservation time, so as to inhibit microbial reproduction and prolong food preservation. The effect of shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

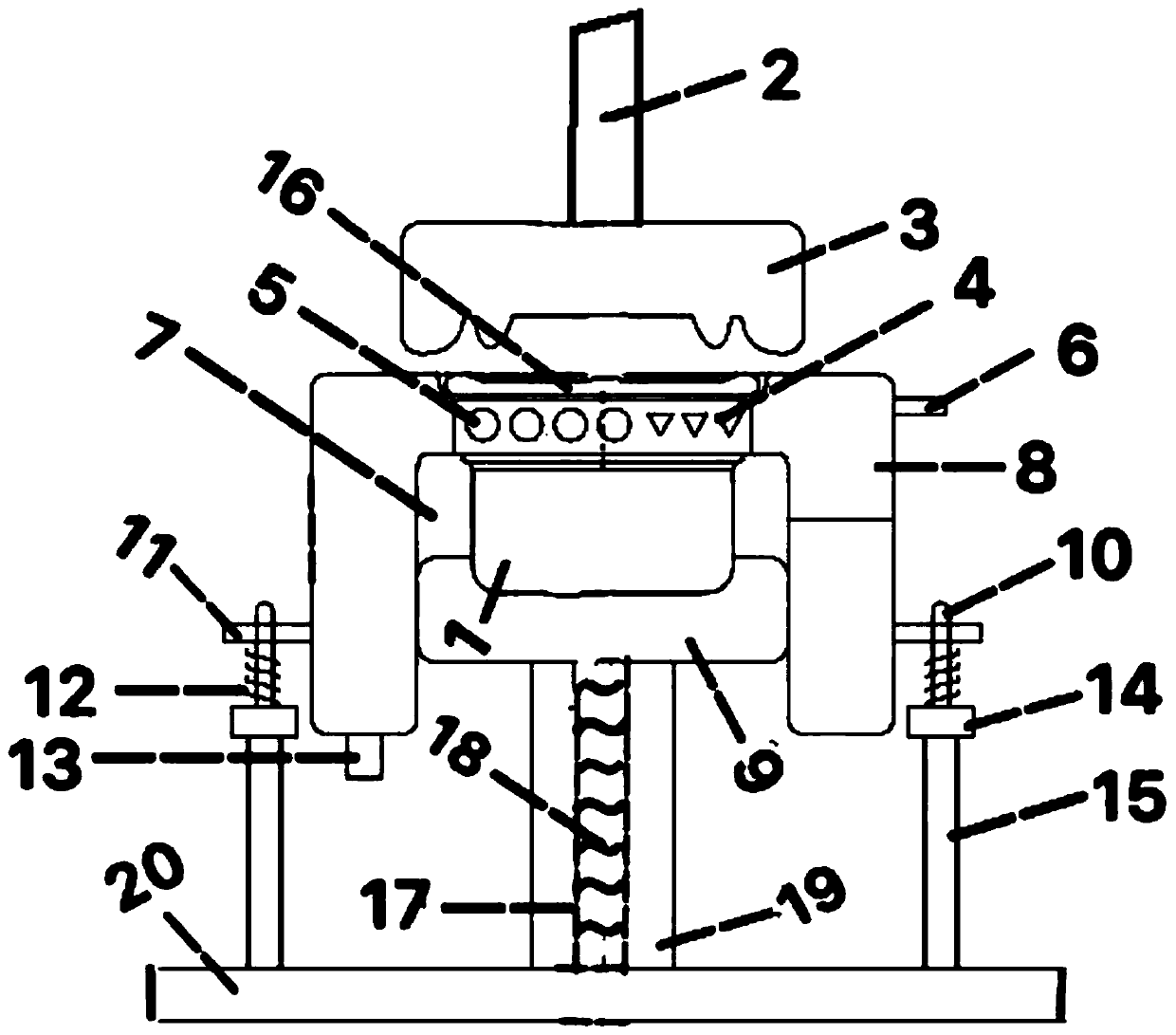

[0016] see figure 1 , a food preservation antibacterial packaging tank vacuum nitrogen charging device, including a main device base 20, a tray telescopic base 19 is provided on the main device base 20, and a tray spring telescopic rod 17 and a tray telescopic spring are arranged inside the tray telescopic base 19 18. The tray telescopic spring 18 is set on the outside of the tray spring telescopic rod 17, the top of the tray spring telescopic rod 17 is connected to the tank tray 9, and the tank tray 9 is used to lift the food packaging jar 1 to facilitate fixing the food packaging jar 1 After vacuuming and nitrogen filling work, the pallet spring telescopic rod 17 is used to eject the packaged products, and a pressure spring is arranged in the center of the pallet spring telescopic rod 17, and the pallet telescopic spring 18 is the pallet spring telescopic rod 17 for ejecting the package The power source of a good product; a nitrogen space 8 is set outside the tank tray 9, an...

Embodiment 2

[0022] On the basis of Embodiment 1, the base 20 of the main body device is also provided with a tank tubular positioning column 15, and the pressure regulator 14 is fixed on the tank tubular positioning column 14, and the pressure regulator 14 is provided with There is a tank body stroke control column 10, the top of the tank body stroke control column 10 is provided with a stroke regulator 11, the stroke regulator 11 is docked with the outer wall of the nitrogen space 8, a stroke control spring 12 is set on the tank body stroke control column 10, the stroke control The spring 12 is located between the stroke regulator 11 and the pressure regulator 14. The can body tubular positioning column 15 is used to adjust the pressure on the food packaging can 1 during the packaging process. The stroke regulator 11 is convenient for packaging according to different The standard food packaging jar 1 is set for pressure regulation, and the pressure regulator 14 is used to adjust the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com